For all of you seeking tougher 3D printing materials, carbon fiber 3D printer filament presents a relatively easy alternative.

Instead of opting for much more expensive and demanding materials such as polycarbonate (PC) or PEEK, carbon fiber is the way to go. With the benefits of cost reduction, you also get the increased level of strength provided by the carbon fiber particles.

So, overall, you get greater dimensional stability that helps you avoid warping and shrinking. But when it comes to buying a carbon fiber 3D printer filament, you need to take some points into account. And we will take you through those points in this article.

But before that, let’s get to know what makes carbon fiber so special from other materials. It is a lot more advanced material than say metals or any other that is quite ancient.

After going through the carbon fiber material in brief, let’s look at the characteristics of the same and then get to the overview of carbon fiber 3D printer filaments, and the printer settings that you need for the same.

Before concluding, we will also make you familiar with the top brands, the carbon fiber 3D printer filaments which offer very good quality filaments and can easily comply with your 3D printer. Excited?

What is Carbon Fiber?

Produced for the first time by Joseph Swan in 1860, carbon fiber is manufactured from a long chain of carbon atoms bonded together. The diameter of the chain usually ranges from 5 to 10 micrometers and varies in length according to its application.

With the passing of time, carbon fiber has become popular across many industries not only because it offers interesting properties, including high stiffness, high tensile strength, but also because of being low weight, high chemical resistance, high-temperature tolerance, and having a low thermal expansion.

Pure carbon fiber is normally at least five times stronger than steel and twice as stiff. Despite all this, it is lighter in weight.

So imagine these characteristics, because they are the ones that make the material suitable for applications that rely on a material’s properties to optimize performance.

So, fields such as aerospace, automotive, military, or civil engineering are some of the industries in which the material finds the most use.

Typical characteristics of carbon fiber

- Commendable physical strength, toughness, and yet light in weight.

- Excellent vibration damping.

- High dimensional stability.

- Low coefficient of thermal expansion.

- Low abrasion.

- Good electrical conductivity.

- Is biologically inert and x-ray permeable.

- Resistance to fatigue.

- Self-lubrication.

- High damping.

- Good electromagnetic properties.

- Chemical inert and has high corrosion resistance.

After having gone through a brief about carbon fiber and its characteristics, let’s explore Carbon fiber 3D printer filament.

Overview – Carbon Fiber 3D Printer Filament

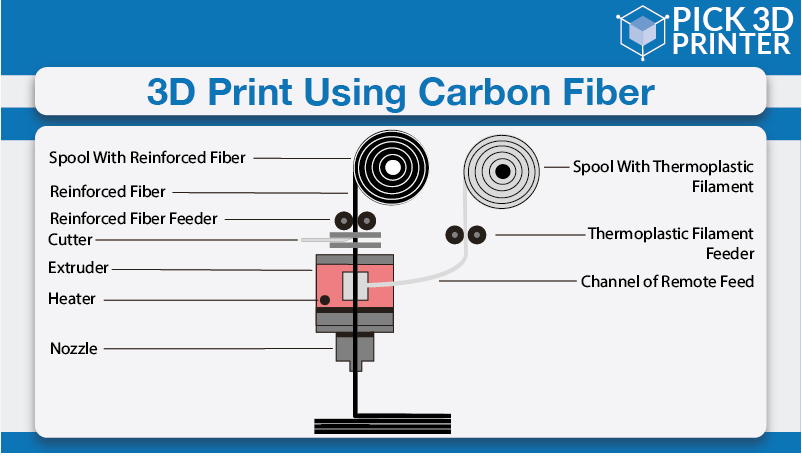

Using short carbon fibers comprising of segments less than one millimeter in length, in a carbon fiber 3D printer filament, the fundamental material is mixed with a thermoplastic known as the base material.

Carbon fiber 3D printer filament can be bought with PLA, PETG, Nylon, ABS, and Polycarbonate. Because these fibers are extremely strong, they can cause an increase in the overall strength and stiffness of filament.

Additionally reducing its overall weight! One point that you must note is that: the 3D printing requirements for carbon fiber filaments should be matching the characteristics of the base material that the carbon fibers were added to.

Some brands have developed carbon fiber filaments for using it in more technical applications. These filaments use high-performance polymers (HPPs) such as PEEK or PEKK as the base material.

Because of the same reason, they not only offer the benefits of HPPs such as a) durability, b) strong mechanical performance, c) strong chemical performance, but also an improved strength-to-weight ratio.

Although you will have to adjust the printing parameters as HPPs rely on extruders that can reach around 400°C, there are systems that have heated chambers and build plates.

Can you 3D Print Using Carbon Fiber Filament?

While printing with carbon fiber filaments, note that the printer settings will vary based on your base material. This means that, if you are printing with carbon-fiber infused ABS, then it is advisable to use the optimal settings for ABS.

So, check out the heated bed temperature settings, adhesion, printing speed, and cooling fan settings for the base material while printing with carbon fiber filaments. For getting aid with the best printer settings, you can check out with your printer manufacturer.

Things to remember when printing with carbon fiber filaments

Below mentioned are the three most important parts to take care of while 3D printing with this filament.

Nozzle

The carbon fibers infused into the filament are quite hard and can wear down on the nozzle of your 3D printer, especially the heated end after repeated use.

Brass nozzles – the most found in 3D printers today, are soft and especially vulnerable to wearing down by carbon fiber.

A completely worn-out nozzle will drastically change the way in which molten filament flows to the print bed. As a result, the prints have very poor quality!

To ensure your nozzles are maintained in good shape, it is recommended to use a nozzle made of 100% heat-treated steel.

Such nozzles are highly durable to withstand the abrasive properties of carbon fiber. Also, they are known to be less thermally conductive than brass.

Meaning that you may have to set your printing temperature 20 to 40 °C higher than usual for preventing clogging at the extruder due to the cooling down effect of the filament. Also, the carbon fiber infused into the filament does not melt along with the base plastic material.

This is another challenge while using carbon fiber filaments, as they can easily clog the extruder nozzle, especially during retractions.

Retraction

It is recommended to disable retractions completely when printing with carbon fiber filaments. In case you cannot completely help it, then use a design that minimizes retraction distances.

There have also been cases in which users have reported better results when using nozzles with larger bores. Doing so reduces the chances of clog formation.

Nozzles with a diameter of 0.6mm to 0.8mm bores are also advisable, although 0.4mm to 0.5mm bores are known to be used with a little difficulty.

Print Speed

As usual, printing at a low speed puts less stress on the extruder. Also, it reduces the chances of clogging in the nozzle.

So, it is recommended that printing at a speed 50% lesser than the regular printing speed for the material of your choice.

This will indirectly convey to you what works best. At best, around a 25% printing speed reduction is known to be the best print speed.

What are the Pros and Cons of Carbon Fiber 3D Printer Filament?

Despite offering wonderful strength and many other features, the filament has its own flaws too.

- The filament offers increased strength and stiffness in parts manufactured using it.

- They are known for providing good dimensional stability.

- Overall, the surface finish of parts and functional prototypes manufactured using the filament is decent.

- The parts are light in weight.

- Frequent clogging in nozzle.

- Wears down brass nozzles and requires special hardware.

- Polymer/carbon fiber mixture increases the material’s brittleness which makes it less suitable for a certain type of applications

What are the Best Carbon Fiber Filament Brands?

After seeing an increase in demand for this filament, many companies have started manufacturing it, however, not each of those offers good quality filaments.

So, it is advisable to search for the below-mentioned brands which are handpicked based on their reliability in the filament market.

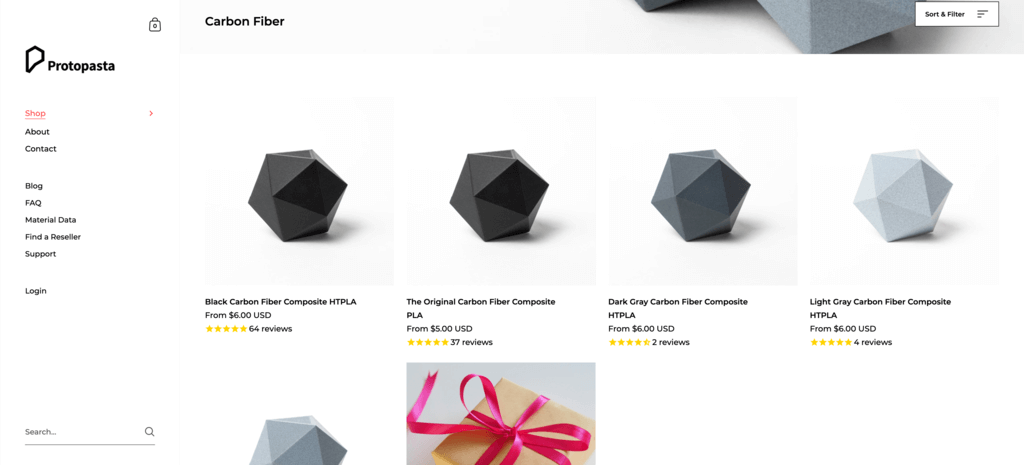

Proto-pasta

Offers two filament diameters; 1.75 mm, and 2.85 mm. The density of the filament is 1.3 grams per cubic centimeter. Recommended bed temperature is 50 °C (not required, but if available then preferred).

Similarly, recommended hot end temperature range is 200-230 °C. The price of this filament is $30 for 500g.

Proto-pasta’s carbon fiber PLA is perhaps the easiest material to print due to its base material. The company claims how its filament offers great layer adhesion, low warpage, and a nice matte finish.

The bulk material of this filament contains 15% (by weight) chopped carbon fibers, which makes it more brittle than standard PLA.

MatterHackers

Available in two filament diameters 1.75 mm, 2.85 mm, this brand has a density of 1.0 grams per cubic centimeters.

It is recommended to have a bed temperature range of 60-65 °C with PVA glue stick bed material while printing with carbon fiber filament.

Whereas the hot end temperature range is advised to be around 250-260 °C! This filament is priced at $60 for 500 g.

Composed of a nylon base with 20% (by weight), MatterHackers micro-carbon fibers combine the durability of nylon and the stiffness of the chopped carbon fibers.

Overall, what you get is a tough, shatter-resistant material ideal for producing functional parts.

Nylon is known for being a difficult material to 3D print; when infused with carbon fibers it provides enough dimensional stability to reduce warping significantly.

3DX Tech

The carbon-fiber-reinforced ABS offered by 3DX Tech is made from premium Sabic MG-94 ABS with 15% high-modulus carbon fiber.

According to the company, besides increased stiffness, the filament also offers higher chemical resistance, dimensional stability, and ease of printing.

3DXTech is an American filament manufacturer offering a wide range of carbon-fiber-reinforced materials, the company’s CarbonX product line includes: a) composites of PLA, PETG, ABS, polypropylene (PP), polycarbonate (PC), b) different types of nylon (PA6 and PA12), and c) even higher-grade plastics such as PEI, PEEK, and PEKK.

Its carbon fiber 3D printer filament is available in two diameters: 1.75 mm, and 2.85 mm.

The recommended bed temperature range is 100-110 °C (with Kapton tape or ABS/acetone slurry). Whereas the hot end temperature range should be 220-240 °C. The filament is priced at $60 for 750 grams.

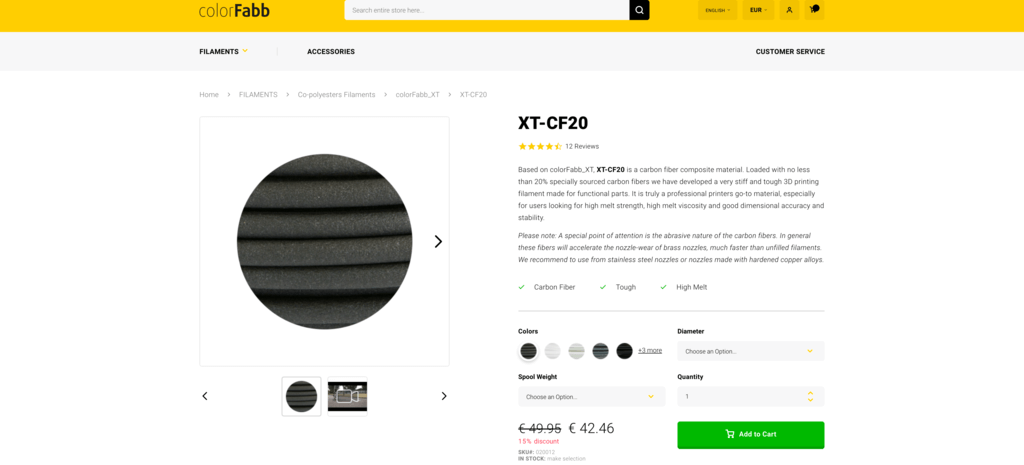

Colorfabb

This 3D printer filament manufacturer claims that its XT-CF20 has great dimensional stability and heat resistance. Additionally, it’s ideal for drone parts and automotive prototyping.

Colorfabb recommends Active cooling at 50 to 90% power and when the print is finished, you are advised to let the build plate cool down to room temperature before attempting to remove the part.

XT-CF20 has a mixture of Colorfabb’s proprietary PETG Amphora 3D polymer with up to 20% carbon fibers. It’s obtainable in two diameters i.e. 1.75 mm, and 2.85 mm.

The density of the filament is 1.27 grams per cubic centimeter. It is recommended to have a bed temperature range of 60-70 °C while printing with the filament and a hot end temperature range of 240-260 °C. The price of this filament is $60 for 750 g.

eSun

Available in two diameters, 1.75 mm, and 2.85 mm, eSun’s carbon fiber filament has a density of 1.20 grams per cubic centimeter and it is recommended to be printed at a bed temperature of 80 °C, hot end temperature range of 240-260 °C. The price of this filament is $45 for 500 g.

In addition to the properties such as increased stiffness and wear resistance, this filament is flame-retardant (UL94-V2), which makes it extremely useful for applications susceptible to higher temperatures.

As with other carbon-fiber-reinforced filaments, the company recommends using hardened nozzles while printing with this material as well.

The Conclusion

Having stated that, 3D printing with carbon fiber filament has its own issues. The infused carbon fiber particles are not known to melt by the nozzle during extrusion. And this may lead to frequent clogging.

Additionally, carbon particles work as abrasive agents during extrusion, which over the passing of time will wear down a brass nozzles’ internal bore. So, a lot of care would be needed on your part.

Special nozzles like hardened steel are suggested for printing with carbon fiber 3D printer filament. The main difference that it will make is, the fibers can clog the nozzles of the 3D printer.