In the list of 3D printers that we are going to share with you in this article, we have classified metal 3D printers into three different categories that will let you analyze them easily based on cost while you are out there buying a 3D printer.

It is to be noted here that in recent years, companies manufacturing these machines have made immense efforts to make them more and more accessible as well as affordable than ever.

So, your question i.e. What does this and that metal 3D printer cost?

This would be answered in this article along with other questions that surround that printer.

How much does a metal 3D printer cost?

To give an answer that can be well understood to all, we will use comparison criteria.

Like metal 3D printers, we have 3D printers based on other materials as well.

Like we have 3D printers based on thermoplastic filaments, 3D printers based on thermoplastic resins, etc.

If you make a comparison of the cost of printers that are based on thermoplastic filaments, resins, and metal 3D printer. Metal 3D printer cost will be more than the other two.

And the reason for this is not only the cost of material that is used for 3D printing of parts and functional prototypes but also the 3D printing technology which is been employed in the task.

In our list of 3D printers, you would read about the 3D printing technology that has been used by every metal 3D printer for manufacturing. Now let’s dive into the list.

List of metal 3D printers

Like we mentioned while starting this article, this list is divided into three categories so that it is easier for you as a user to access while buying a metal 3D printer.

So, as a user, a comparison of different printers can be made on various criteria and in this list, we have made build volume as a criterion for categorizing metal 3D printers.

Build volume is one of the most important criteria to observe when you are out in the market surveying different printers for choosing which one is best for you.

Obviously, the more build volume you have, the larger would be the volume of the part or functional prototype you would be able to build, that’s the golden rule of thumb you’ve got to keep in mind.

Low Build Volume Offering Metal 3D Printers

All of the printers mentioned in the list below would have a lesser build volume than the next category of 3D printers.

Sharebot MetalOne

Based on the Direct Metal Laser Sintering technology of 3D printing, this printer offers a build volume of 65 mm * 65 mm * 100 mm.

The feedstock of this printer needs to be filled with metal powder for starting the printing process of this printer.

Metals with which you can 3D print using this printer are Stainless Steel 316L, and Cobalt Chrome, you need Nitrogen-Argon gas 0.25 liters per minute for maintaining the inert gas environment inside the print chamber of this printer.

The build platform on which printing takes place is the one that is established by Sharebot Snowwhite, which is a predecessor of this 3D printer.

The difference between both of them is that the predecessor used a variety of sintered polymer powders, whereas the MetalOne uses a powerful laser for selectively sintering the metal powder.

The inert gas circuit of this printer is equipped with a group of three filters and its system has the advantage of being a dust-free environment and the ability to sinter any metal dust including that of reactive metals such as titanium.

For knowing the price of this printer, you would have to request the company to send you a quote for this printer.

This, you can do from the printer’s website, on the webpage dedicated to this printer.

EOS M100

Similar to Sharebot MetalOne, the EOS M100 is also based on Direct Metal Laser Sintering 3D printing technology. This printer offers a build volume of 100 mm * 100 mm * 95 mm.

The feedstock of this printer needs to be filled in with EOS metal powder for ensuring the start of the printing process.

Available metals that you can 3D print with, using this printer are Stainless Steel 316 L, Cobalt Chrome SP2, and Titanium 64.

The inert gas requirement for the printer’s printing chamber is gas at 50 liters per minute, increasing the flow to 600 liters per minute during flooding, and decreasing up to 2.5 liters per minute during the printing process is going on.

In the list of 3D printers that are mentioned on the EOS’ websites, the M100 is an entry-level 3D printer that is equipped with 200 Watt fiber laser for melting and fusing fine metal powders such as aluminum, maraging steel, high-grade steel, titanium, nickel, and cobalt chrome alloys.

For reducing the post-processing of parts or functional prototypes and cleaning time, there is a separate system in the printer which allows parts to be produced quickly than otherwise.

And for making the maintenance and operation easy, the modular design of the printer is all there to help.

For getting the price of this printer, you would have to request a quote from the company. This, you can do from the printer manufacturer’s website.

|

Admatec Admaflex 130

Based on the Digital Light Processing technology of 3D printing parts and functional prototypes, this printer offers a build volume of 96 mm * 54 mm * 110 mm.

Admatec Admaflex’s feedstock takes in the metal-photopolymer slurry for starting the 3D printing process.

The available metals to 3D print using this printer are Stainless Steel 316 liters, 17-4 PH, and Inconel: 625 Copper.

In comparison to MetalOne and EOS M100, there is no need for inert gas when you are printing with this printer.

The slurry is generally made of ceramic or metal powder with a little bit of photopolymer binder composition.

This printer cures the entire layer of any model in snapshots i.e. with a reel of continuous tape distributing the material which is necessary for a given layer, before winding on, reclaiming unused material, and exposing the fresh slurry in this process.

The main benefits of using this 3D printer are:

- High throughput.

- Cleaner workplace and no material waste.

- Quick and easy material switch.

- Works with broad viscosity range.

There are two Admaflex printers:

- Admaflex 130.

- Admaflex 300.

As we are talking about the low volume range of metal 3D printers, right now we are discussing Admaflex 130, the printer that offers a lower build volume than Admaflex 300.

Although we will mention Admaflex 300 in the latter part of this article.

You need to request a quote to get the price of this printer, which can be done easily from the website of the printer manufacturer.

After having seen a list of low volume metal 3D printers, you have got an idea that metal 3D printer cost is something not out there in the open, even if you refer to the websites of the manufacturers.

So, for getting a metal 3D printer cost, you would have to fill the request form and Get A Quote from the concerned manufacturer for its metal 3D printer.

Let’s look at the medium volume metal 3D printers.

Medium Build Volume Offering Metal 3D Printers

All the printers mentioned in the list below have greater build volume than the ones that are mentioned till now.

Aurora Labs S-Titanium Pro

Based on the same 3D printing technology that EOS M100 is based on, this printer offers a build volume of 200 mm * 200 mm * 250 mm.

The feedstock of this printer needs to have additive manufacturing grade metal powder for starting its printing process.

For inert gas inside the print chamber, you need Argon at 8 to 11 liters per minute after the initial flush at 25 liters per minute.

Flexibility in terms of material experimentation is the key attracting factor that this printer carries with its name.

The printer has an open system that benefits education and research regarding 3D printing technology.

On the website of its printer manufacturer, the fast speed of this printer is something that has been boasted a lot.

Apart from that, the cost of manufacturing one part, and its efficient power usage is also mentioned on the website.

The price of the printer is not explicitly mentioned on its website.

So, you would have to get a quote for it. Although as reported on the website All3Dp, the price of this printer is $55,000.

Admaflex 300

Based on DLP 3D printing technology, this printer offers a build volume of 260 mm * 220 mm * 500 mm.

The parts and functional prototypes built by this printer are known to have a layer thickness range of 10 to 200 micrometers. Admaflex 300 operates on a build speed of up to 3000 layers per hour.

The working temperature required for this printer is 22 degrees Celsius with a tolerance of two degrees Celsius.

Four of the printer’s features mentioned on the website of its manufacturer are Large Build Volume, Patented Feedstock System, Modular Concept, Open platform, and In-process monitoring system.

The price of this printer can be known by contacting the manufacturing company that is based in the Netherlands.

The company offers Materials, and Services apart from 3D printers.

After having seen medium build volume offering metal 3D printers, we will now have a look at high build volume offering metal 3D printers.

|

High Build Volume Offering Metal 3D Printers

This category of 3D printers will have the highest build volume amongst all the three categories mentioned in this article.

Concept Laser XLine 2000R

Based on Direct Metal Laser Melting, this printer has a build volume of 800 mm * 400 mm * 500 mm.

The feedstock of the printer needs to be filled with additive manufacturing grade metal powder.

You can print with the printer using AlSi10Mg (Balanced or Productivity), Titanium Ti6AL4V Grade 23, and Nickel 718.

The inert gas required for the print chamber is Nitrogen in the quantity range of 17 to 34 liters per minute.

The machine uses two 1000 Watt lasers for ensuring the production happens on time and high-quality parts and functional prototypes that can be used in automotive as well as aerospace industries.

Sciaky EBAM 300

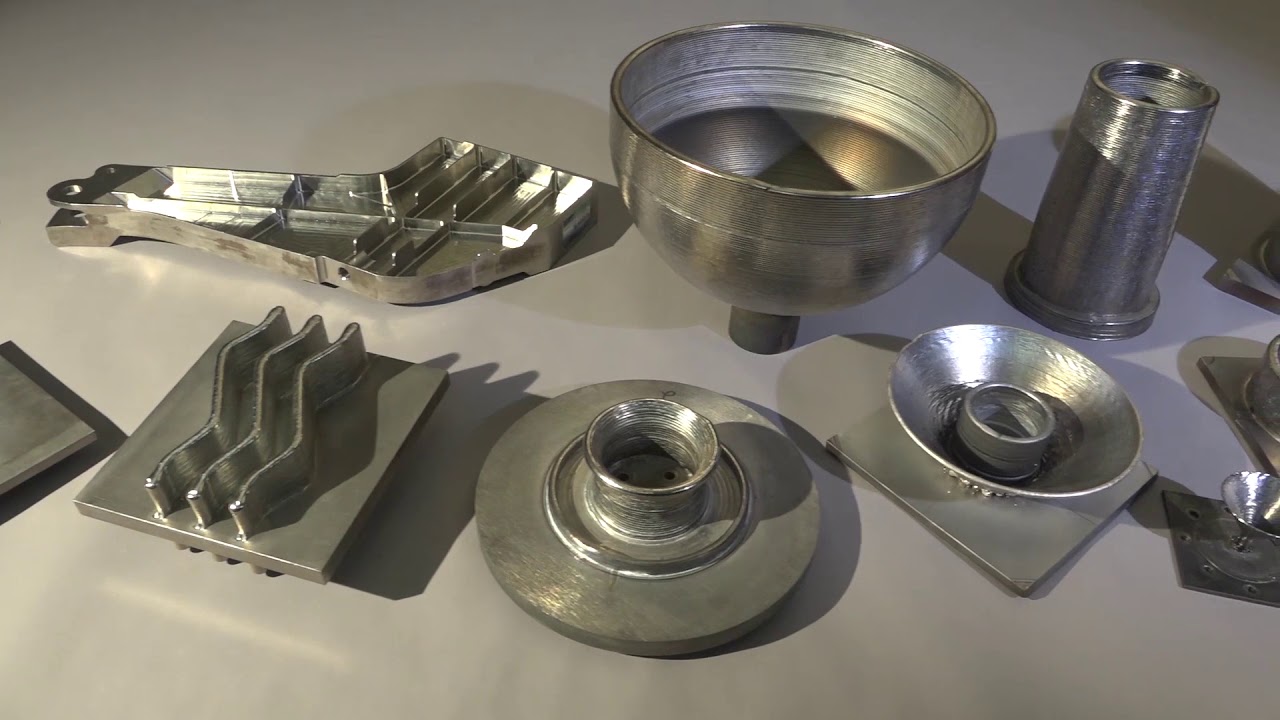

Based on the Electron Beam Additive Manufacturing technique, this printer offers a build volume of 5791 x 1219 x 1219 mm.

The feedstock of this printer needs Welding Wire for starting the printing process of the printer.

The printer allows you to print using Titanium alloys, Inconel: 625, 781, Tantalum, Tungstem, Niobium, Stainless steel: 300 series, Aluminum 2319, 4340 Steel, Zircalloy 70-30/30-70, and Copper-Nickel.

You do not require any inert gas to maintain the temperature of the print chamber.

The machine utilizes a process that is capable of building huge volumes at high deposition rates which range anywhere from three to seven kilograms of metal per hour.

Claims are that parts and functional prototypes that can take up to 12 months can be printed within days of printing with this printer.

To check out the price of printers mentioned in this category, you would have to visit the printer manufacturer’s website and request a quote.

|

The Conclusion

Build Volume is here used as a criterion for comparison of metal 3D printers.

Although build volume is used as a criterion, the cost comes associated with it completely.

As in, the low build volume offering metal 3D printers would also be a metal 3D printer costing low, and vice versa.

So, when you compare them according to the metal 3D printer cost, you would end up with a similar list as you do have up here.

Because the low volume offering is going to cost you lower than the medium and the high volume offering metal 3D printer.

The quality of these metal 3D printers changes according to the 3D printing techniques employed by them.

So, you have to take that into account and ask yourself an important question i.e. till what level are you fine with metal 3D printer cost?

Related Articles