The world of 3D printing is constantly changing because of the ever-evolving 3D printing technologies. One such technology that grew from a hybrid of two of the already existing technologies, SLS and Binder Jetting, is the MJF 3D printing technology.

MJF is an abbreviation for Multi-Jet Fusion. Before dwelling into the world of Multi-Jet Fusion and how it functions inside a 3D printer, let’s go through the overview of SLS and Binder Jetting.

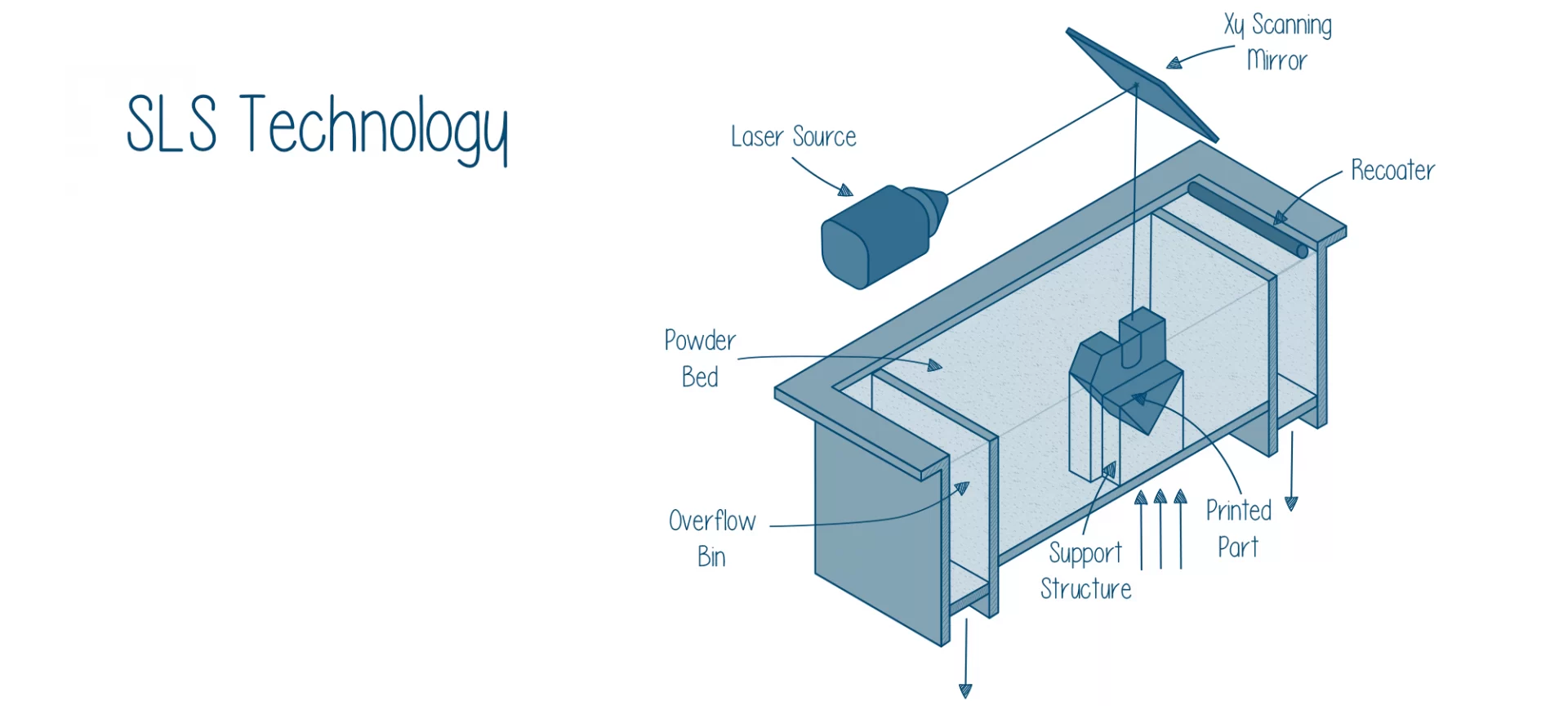

What is SLS 3D Printing?

SLS is the short form of Selective Laser Sintering. It belongs to the same class of 3D printing technologies as MJF i.e. Powder bed fusion.

The difference is that after starting out with the powder, SLS does not continue with jetted adhesive. Instead, the technology utilizes pulsed laser sinters and tiny volumes of Nylon powder together.

The firing of the laser adds a voxel to that location, and as the process goes on, more and more time implies the firing off lots of voxels.

These are then laser-sintered solid with each other from successive layers of powder, leading to a part formation according to the 3D design file.

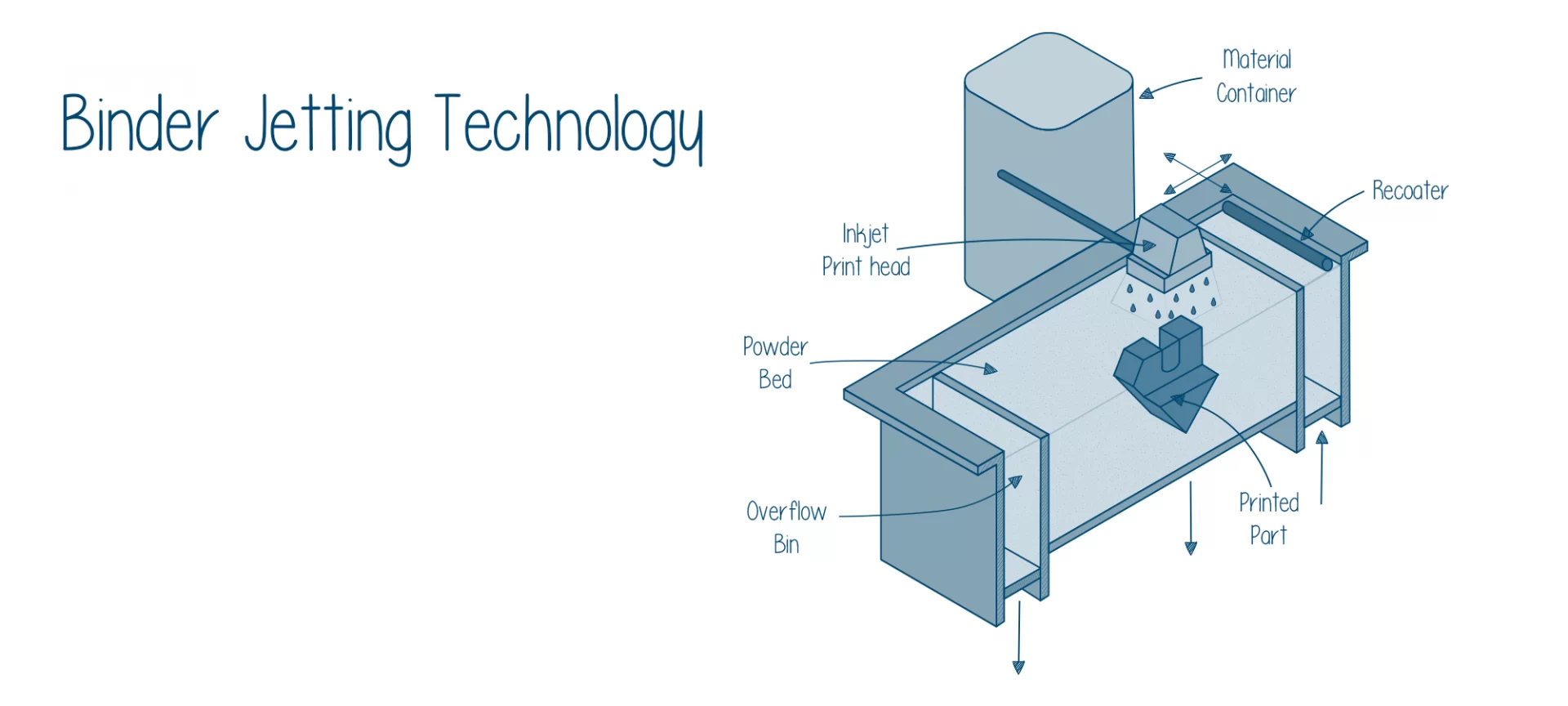

What is Binder Jetting 3D Printing?

This process is easy to understand if you understand the meaning of the words “binder” and “jetting” individually. The substance that plays the duty of binder in this 3D printing process is a printed adhesive and a powder substrate such as sand or gypsum.

What leads into the complete geometry of a part or functional prototype is the pattern of these jetted binders sprayed onto successive layers.

Layer after layer the binder is jetted across, according to the 3D design file, finally leading to the production of the intended part or functional prototype.

Both SLS and Binder Jetting 3D printing technology is known in the market as two of the most successful technologies that can produce high-quality part and functional prototypes.

How is Working of MJF 3D Printing?

This technique is believed to be brought into the market of 3D printing technologies by HP. You may all be familiar with the company as a manufacturer of 2D printers, aren’t you?

Experts believe that because HP was already into the area of heavy-duty 2D printing, MJP 3D printing worked a little more naturally with the company. If you are in your head with the question, “How exactly?” Just wait to find out.

MJF 3D printing powders bed in a better manner than the previously mentioned 3D printing technologies.

When it comes to defining a part’s geometry, the technology does function similarly to binder jetting. But a shift comes in the fusion of the identified powder into a part.

The nuance in this process lets it speed-up the time needed for 3D printing by including technologies of a printing press in two important areas:

- The print head.

- The heater arms that sweep across the fully available print area for each layer of the part.

Three-step treatment of millimeter of every fraction of the part:

- The first step involves the spreading of powder across the print bed of any MJF 3D printer.

- The second step starts the process of depositing millions of drops of light-absorbing ink by inkjet print heads sweeping across the powder-spread. The accomplishment of that defines voxels worth keeping and voxels that will fall away like powder. The surplus inks can help in marking a crisp part boundary and in providing other properties like color.

- In the third step, an infrared heater sweeps across the print bed. Till then, there has been enough absorption of the IR energy from the ink-marked areas for sintering the underlying part. And what is remains is the full-color powder.

This process repeats in MJF 3D printing until the completion of the entire part. After the build is completed, the entire powder bed with the created part is transported to a processing station.

Here the removal of the majority of loose powder is done by an integrated vacuum. Before reaching the finishing department, the parts are bead-blasted for removing any kind of residual material.

In the finishing department, they are dyed black for improving their cosmetic appearance.

Specific use of MJF 3D printing:

- When it comes to achieving a high quality of parts and functional prototypes in no time, Multi Jet Fusion holds a record of finesse like no other 3D printing technology.

- MJF’s ability for producing functional prototypes made of Nylon material and parts for end-production in a single day with quality surface finishes and fine feature resolution is unmatched.

- Manufacturers prefer MJF over 3D printing technologies such as Selective Laser Sintering when they want to strive for more mechanical properties in parts and functional prototypes.

- Some objects demand complex and intricate detailing features. In the creation of such parts, MJF is specifically used because it is able to offer such complexity. This, the technology is able to do by applying fusing agents across the bed of nylon powder and then fusing them into a solid layer via heating elements.

- Companies also offer a fast and advanced way for creating durable parts using commercial grade unfilled Nylon 12 material on-demand.

- Parts that cannot be printed via FDM 3D printing technology because support structures cannot be used in their construction can be printed using MJF 3D printing.

- Some of the most popular applications of this technology are in electronic component housing, enclosures, mechanical assemblies, and durable but accurate jigs and fixtures.

Advantages and disadvantages of MJF 3D printing over SLS and FDM:

Just like every other technology MJF 3D printing is preferred over other technologies due to some reasons and vice versa.

- Fully-functional parts of high quality can be printed using MJF that offers more flexibility than parts and functional prototypes produced using FDM.

- The part of printing a single printed part is very low when printed using MJF technology. Also as soon as the part is printed it is ready for application and requires no finishing, nothing.

- Compared to SLS 3D printing technology, the overall cycle times of MJF are faster.

- The amount of powder that can be recycled from the total powder defined as the wasted powder is more in MJF than in SLS.

- MJF 3D printing is scalable for producing hundreds of thousands of parts and hence more favorable for mass production of components.

- Using some of the HP Fusion printers that are based on MJF, you can print colored parts and functional prototypes.

- Compared to FDM, the build area used for nested parts is denser in MJF.

- The wide range of material options that you get while printing with FDM technology is something you cannot when printing with MJF. The production is limited to two materials i.e. Nylons.

- The wide range of color options that you get while printing parts and functional prototypes with other technologies get limited to Gray and Black, on an industrial scale, when using MJF.

- The 3D printers based on MJF are large and expensive machines that can be hardly affordable by small manufacturers and hobbyists in the field of 3D printing.

- Since the build size of MJF 3D printers is huge, they are not preferred for home 3D printing.

Brief about HP’s Products Based on MultiJet Fusion

There are three printers that HP offers under their Jet Fusion series. They are:

- Jet Fusion 5200 Series.

- Jet Fusion 4200 Series.

- Jet Fusion 500/300 Series.

To give you a better idea about MJF technology, we’d like to share with you a little introduction and features of these three 3D printers.

Jet Fusion 5200 Series

This MJF 3D printer is meant for those users who wish to drive into new growth and expand their volume production. It is robust and manufacturing ready to become an industrial 3D printing solution.

This MJF 3D printer allows you to print using three types of 3D printing materials namely; HP 3D High Reusability PP5 enabled by BASF, HP 3D High Reusability PA 118, and HP 3D High Reusability PA 1211.

All three of them have different characteristics and so do the parts and functional prototypes manufactured by them.

HP 3D High Reusability PP5 enabled by BASF is chemical resistant, weldable, low moisture absorbing, and can be used in making functional parts.

HP 3D High Reusability PA 118 is used for producing ductile quality parts. Whereas HP 3D High Reusability PA 1211 is strong, available at low cost, and produces high-quality parts.

|

Jet Fusion 4200 Series

This MJF 3D printer is specially used for producing quality parts and optimizing productivity and cost. It is the ideal solution for producing a functional prototype and short-run production.

Jet Fusion 4200 Series lets you achieve predictable print time and parts with best-in-class isotropy.

You can also choose from the different print modes that the company has installed in it for achieving mechanical, functional, and aesthetic properties without compromising on accuracy and speed.

The printer also enables you to produce more parts in a day by continuous printing. Its workflow is streamlined and its enclosed print chamber allows for a cleaner experience and automated mixing of materials.

Using Jet Fusion 4200 Series you can reduce your operational costs, invest in a 3D printing solution, and produce a low cost per part.

Jet Fusion 4200 Series allows you to print with five materials namely, HP 3D High Reusability PA 117, HP 3D High Reusability PA 129, HP 3D High Reusability PA 12 GB12, ESTANE 3D TPU M95A14, and HP 3D High Reusability TPA enabled by Evonik. Each of them has different characteristics.

HP 3D High Reusability PA 117 produces high-quality ductile parts. HP 3D High Reusability PA 129 lets you print strong parts at a low cost. HP 3D High Reusability PA 12 GB12 enables you to produce stiff and dimensionally stable parts.

ESTANE 3D TPU M95A14 grants you the access to produce high rebound and good abrasion resistance parts. Lastly, HP 3D High Reusability TPA enabled by Evonik is meant for parts that are easy-to-process, flexible, and light in weight.

|

Jet Fusion 500/300 Series

The main area of application of this MJF 3D printer is in producing parts with full-color, black, or white. It lets you gain voxel control in a very short span of time.

This is one of the most compact Jet Fusion 3D devices produced by HP. It is meant for small to medium-sized product development teams experimenting in the field of 3D printing technology.

Mostly for design firms and universities. The printer aims to increase your productivity by letting you produce multiple design iterations in the amount of time that it takes to produce a single part.

You can also produce engineering-grade thermoplastic parts with optimal mechanical properties using the printer.

This would allow you to stay ahead of the competition by associating yourself with the future-ready MJF 3D printing technology, additionally permitting your print a full-color, black, or white functional parts.

Printing is possible using HP 3D High Reusability CB PA 125. The characteristic of this material lets you print engineering-grade parts in full color, black and white.

The Conclusion

MJF 3D printing prepares you for the future era of digital manufacturing like no other 3D printing technology.

It transforms the part properties voxel by voxel enabling you to apply the part produced by it in many areas.

Smart parts with embedded electronics and integrated traceability are the future that this technology lets us envision.

Overall, HP MJF 3D printing technology lets you print parts and functional prototypes that cannot be printed using other 3D printing technologies.

And this is possible by the control it lets you have over the 3D designing and printing aspect. The complete authority over each voxel via individual agents is not possible to gain with any other 3D printing technology.

Each layer manufactured by this 3D printing technology has agents on the top of it. And the previous layer is so molten that both the layers fuse in a manner that’s very uncompromising.

The result is a stronger, high quality, detailed and functional 3D printed part.