Printing with Nylon may come as a challenge for those who have never used the material before. Likely to be tricky for beginners, Nylon can really make it difficult for you to master its settings.

If you have worked with PLA or ABS before, you must know that every material works differently. While PLA is the easiest to tame, ABS could make things complicated for the first few usages.

Similarly, Nylon is among the stubborn materials with various unique settings needs including Nylon print temperature. Needing high temperature for extrusion, the material definitely is resistant to heat. However, the same property brings with itself a few challenges one must be aware of.

Hence, if you are looking forward to printing Nylon and create precise parts, it is imperative to go through its various properties and find the right settings requirements. Otherwise, you may end up destroying your prints. And who likes to go through the trouble of repeating print jobs?

So, read the 3D printing tips for mastering Nylon print temperature and other parameters necessary for accurate printing.

Nylon – Overview

Nylon which is also referred to as Polyamide is one of the most demanded materials within materials belonging to the plastic family. The material allows parts to stay tough and at the same time flexible.

Thus, offering great strength to the 3D printed parts. Nylon is made of synthetic polymer, made of polyamides. Polyamides are usually polymers that are linked using amide bonds.

Talking about additive manufacturing, Nylon comes with advanced materials. This is because of the fact that the material isn’t very friendly to print.

On the contrary, it requires experience with a proper skill set to master its printing.

Also, one must have the proper machine with a hot end capable of reaching the required temperature to extrude Nylon. Unlike PLA, Nylon print temperature is much higher.

To be precise, Nylon needs a temperature over 250 degrees Celsius for extrusion. You may find a few brands offering printing temperatures as low as 220 degrees Celsius. And, this is because of the difference in their chemical composition.

Hence, if you do not have a printer that can reach a significant printing temperature, you can always choose the versions with lower temperature requirements.

Or else, you can also choose to swap to an upgraded hotend for working with nylon at 250 degrees Celsius.

Why Choose Nylon?

You must be thinking: why all the extra hard work of switching to Nylon when it’s easier to work with other alternatives?

Well, the answer lies in the various perks that the material offers, which otherwise isn’t possible with PLA or ABS.

Physical Properties

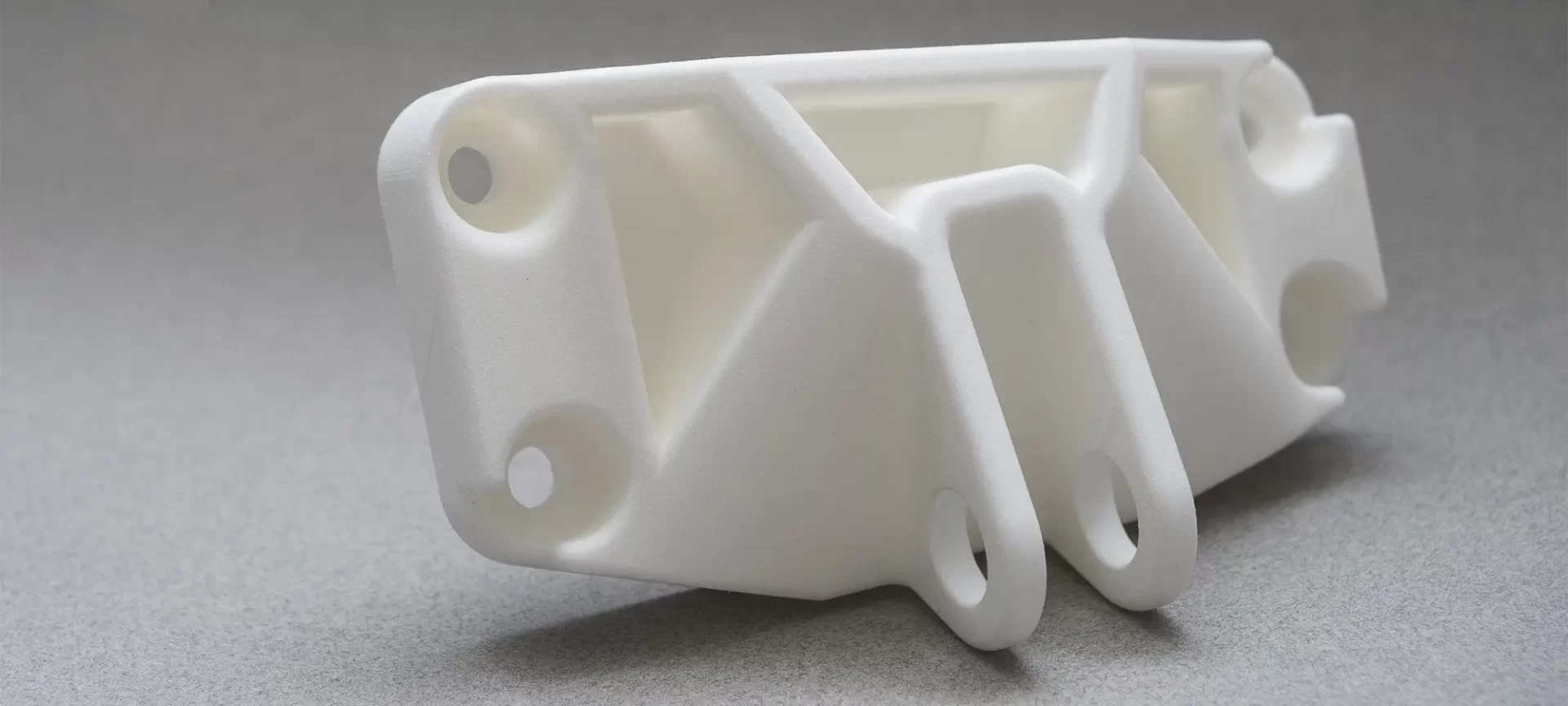

As already said, despite its difficult printing settings, Nylon is popular because of the properties it shares. It’s the most chosen material for industrial 3D printing applications.

Thanks to the strength and durability it offers. Its abrasion-resistant property makes the material fit for a number of tough applications.

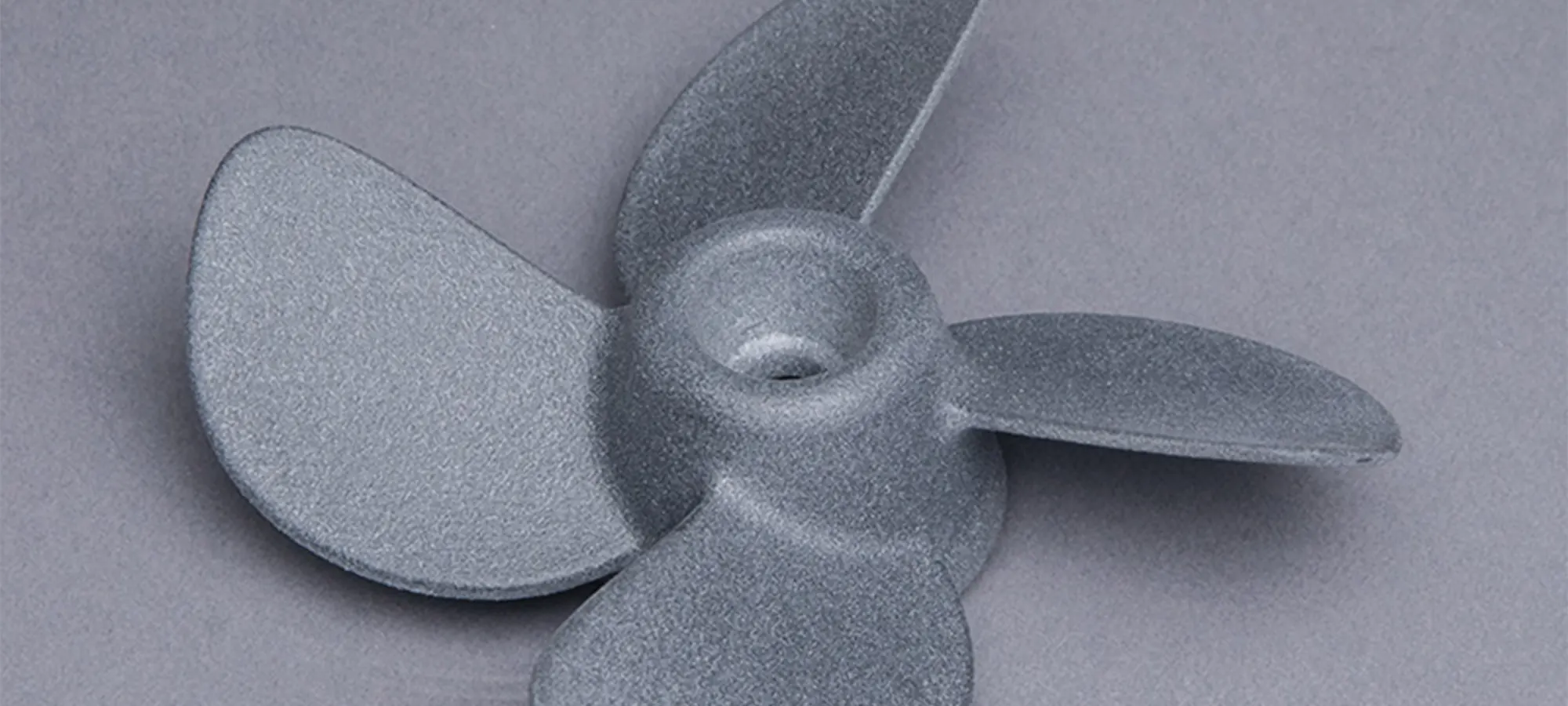

If your parts are considerably thinner, printing with Nylon would allow achieving flexibility along with toughness. Isn’t that a killing combination?

In addition, the material has a low coefficient of friction. Therefore, users can make parts mean for functional moving prints.

Hence, Nylon is very much preferable for creating functional prototypes, gears, living hinges, along with many similar end parts.

Chemical Properties

Making Nylon such interesting is the other two chemical properties. And, it’s very necessary to understand each of these properties and how these affect the print settings.

The first one is the melting point of Nylon which is too high. Hence, as mentioned before, you need a printer with a hot end capable of reaching a high temperature for extrusion.

Another important chemical property is that Nylon is hygroscopic. This means that the material absorbs moisture easily. While it may come as a perk for users when painting the parts made of nylon.

Because the surface easily adheres to the paint and makes it easier to color the prints as needed. However, the same property also brings a challenge for the users.

Nylon can easily absorb moisture from the atmosphere. Hence, users need to have a proper storage solution for the material.

What Are The Common Issues When Printing with Nylon?

Now that we have discussed nylon properties, it’s time to understand the challenges that are often more pronounced with the material.

These challenges if not handled correctly with the right Nylon print temperature settings can certainly end up in failed prints.

So, let’s check out the problems that users often encounter when working with Nylon.

Warping

By now, you must have got an idea of the low-temperature Nylon exhibiting different chemical properties. While these may not be very prone to warping, high-temperature Nylons are.

This is because of the high-temperature change that is prevalent between the extruded material and the ambient surrounding. While heated beds may come in handy when trying to resolve the issue, its isn’t sufficient all the time.

Hence, one must ensure that the printing happens within an enclosed chamber. Usually maintaining a temperature around the prints at 45 degrees Celsius helps in eliminating the warping issues.

Doing so can reduce the difference in the Nylon print temperature, offering a consistent flow of heat around build space.

There are other ways too for avoiding warping. For instance, keeping the first layer a bit thicker than the subsequent ones and printing it with a lower speed than the original print speed.

Proper Machine Needed for Printing Nylon

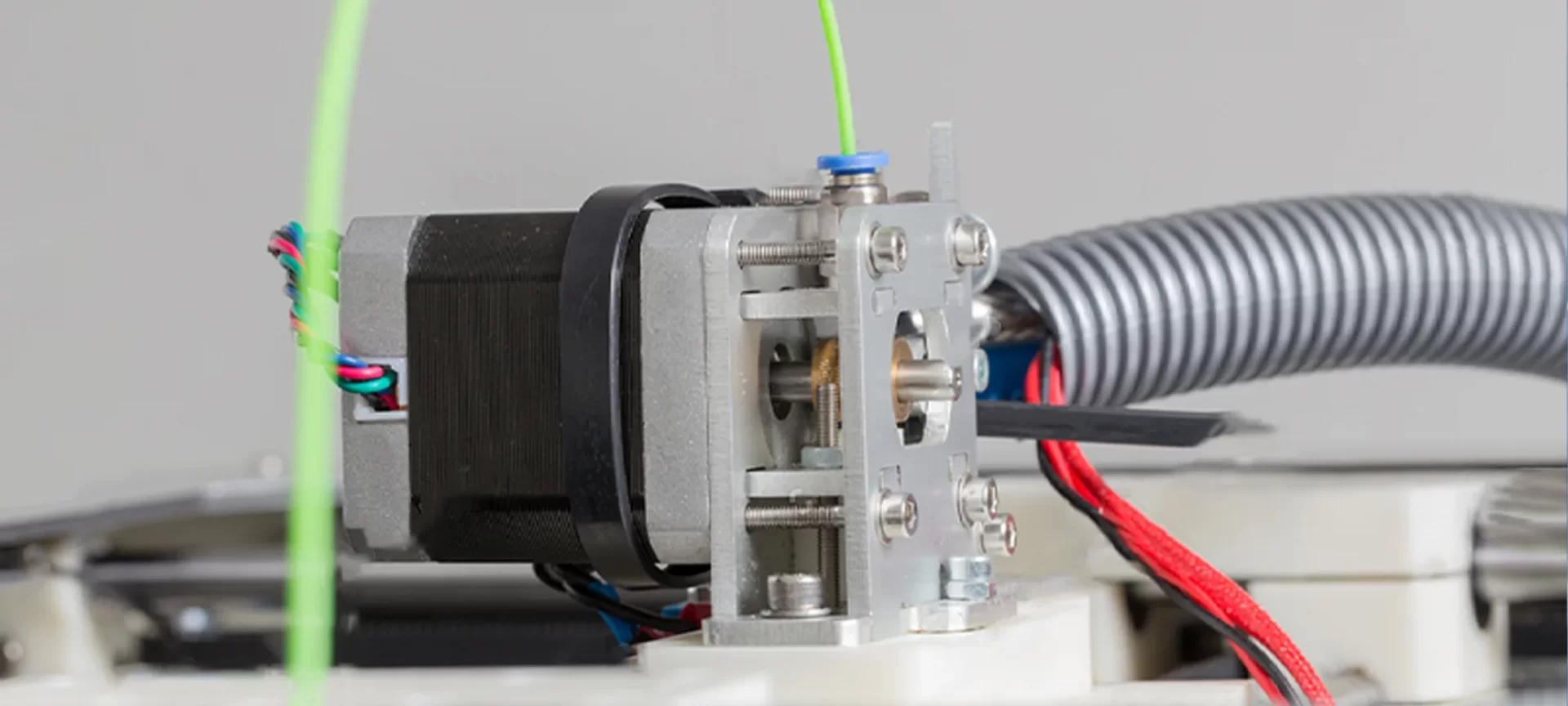

As discussed, Nylon has a higher melting point. This means, to extrude Nylon material, the hotend must enable a temperature higher enough to melt nylon before extruding it on the build plate.

Usually, 3D printers are equipped with hotends that can support the temperature required for printing with PEEK or PTFE. And, these materials start to break when exposed to a temperature higher than 240 degrees Celsius.

When this happens, these materials start emitting noxious fumes. On the other hand, Nylon filaments require a hotend that reaches 250 degrees Celsius to the least.

Hence, it is very important that you make sure to buy the right 3D printer. Or else, if you already have a printer without a capable hotend to work with Nylon, you can upgrade to one. Just change the hotend that can work with Nylon and you can start printing with this stubborn material.

What Are the Recommended Settings For Nylon Print Temperature?

Not every 3D printer can let you print Nylon. While that is certainly true, it is also possible to upgrade a few components and start working with the material, as briefly described earlier in the article.

So, what are the Nylon print temperature settings that could allow you to create astonishing prints? Well, let’s read through.

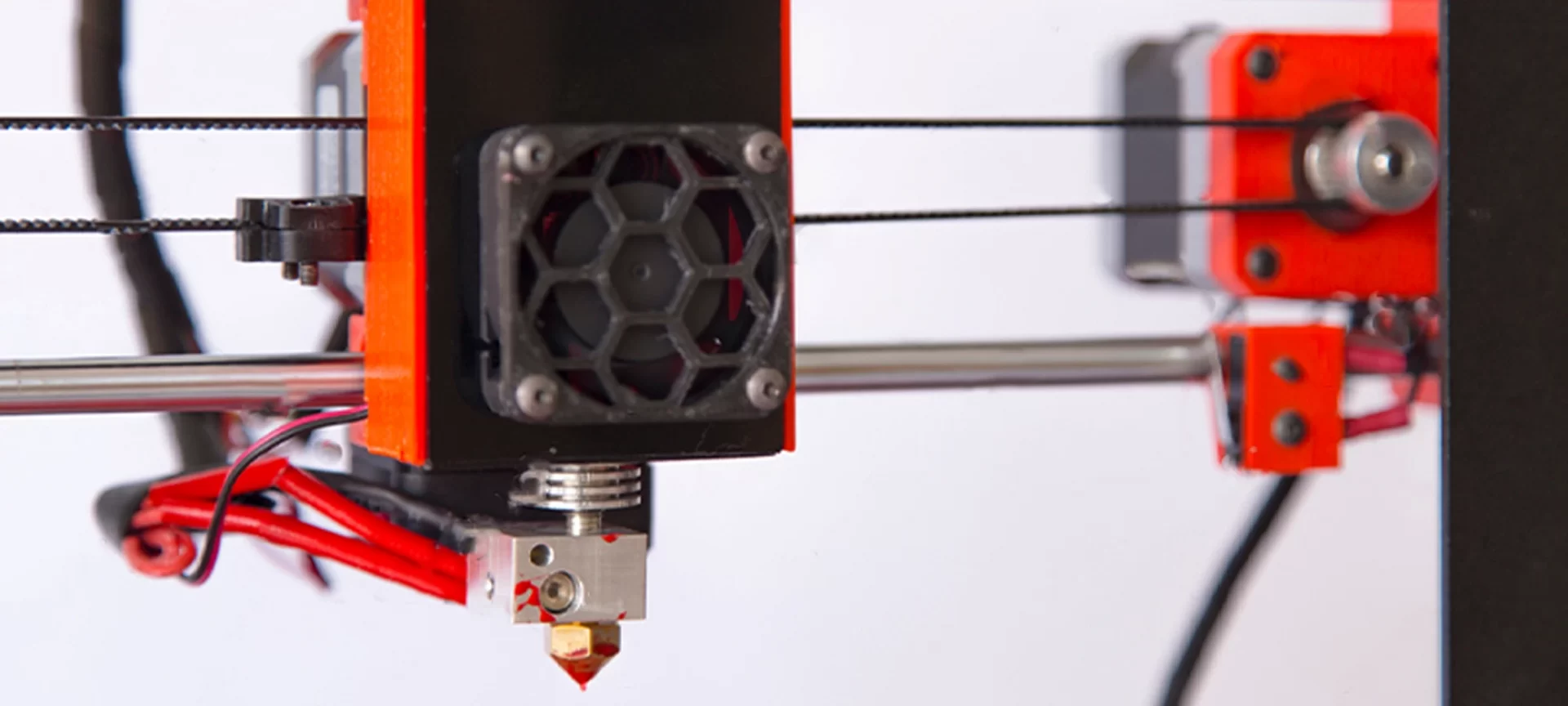

Extruder Temperature

There must not be any second thoughts when working with Nylon. You will encounter issues, sooner or later. That is why users must know the right settings that could allow them to avoid such challenges.

When talking about Nylon print temperature, the first setting that comes to mind is the extruder temperature. The extruder temperature ranges between 240 degrees Celsius to 260 degrees Celsius.

For printing with Nylon, it is recommended to start with 250 degrees Celsius hotend temperature. However, different brands’ settings differ.

So, you must try incrementing the temperature by 5 degrees Celsius with every new print until you achieve a durable and smoother surface finish.

Do not forget, there are low-temperature versions also available for Nylon. Hence, the correct extruder temperature may vary widely for different nylon-based filaments and brands.

It is always recommended to read the complete printing direction for each Nylon filament you purchase and look for the advisable print temperature settings.

Print Bed Temperature

Then comes the print bed temperature. And, it definitely holds huge importance when printing with Nylon. As already discussed, printing with Nylon will require a heated bed, no matter if you are printing on Glass or Garolite.

However, this is not all. You will require a glue stick, mostly PVA-based for increased bed adhesion.

Precisely, if you are working on glass plates, the build plate must be able to reach a temperature of 75 degrees Celsius.

Given that the build surface is applied with a thin layer of glue, especially when finished with a cross-hatch pattern. The settings work astonishingly for glass plates.

With Nylon printing, Garolite surface is a very common pick. However, you do need a heated bed in this scenario as well.

You can use Garolite surface directly over the heated bed. Or, you can also use the same with a glass sheet, PEI glass, and even the FlexPlate System.

Attaching Garolite sheet with a build plate will enable the transfer of heat to the build surface.

Also, do not forget to add PVA-based glue to the build surface. This will again help in increasing the first layer adhesion to the bed.

Moreover, if you are in need of stronger bed adhesion, try sanding the Garolite surface evenly to achieve a textured surface. With that, the material will hold on to the surface more firmly.

When printing with a Garolite surface, you must maintain the bed temperature ranging between 55 degrees Celsius to 65 degrees Celsius.

The exact temperature will depend on the brand of the nylon material as well as which nylon-based filament you choose to print with.

It is always advisable to read the guidelines for Nylon print temperature that brands usually mention for their materials.

Ambient Temperature

Maintaining a consistent temperature around the build surface is very crucial when printing with Nylon. This is why an enclosed frame is required for printing with this material. It helps avoid warping too.

The recommended ambient temperature is 45 degrees Celsius for finer results.

Additional Printing Tips

Nylon does need special storage because of its property of absorbing moisture from the air. Unlike many other alternatives, keeping Nylon spool exposed to the open surroundings will hamper its quality.

Hence, if printed with moisture-exposed Nylon filament, one can experience parts with foggy rough surfaces.

It is even possible to see some small holes and bubbles on the print’s surface.

While the looks will be compromised, the parts may also fail to exhibit desired strength and performance. Hence, if you are working with Nylon, ensure to place the leftover spool right away inside the air-tight container once you are done printing.

In case, removing and storage seem like a constant job, you can buy the storage containers which lets you print with the filament while keeping it dry at the same time.

One more way to overcome the issues with moisture is to dry the Nylon spools inside the food dehydrator before printing.

And, if you did not know, Nylon can be a great hack for those wanting to clear the nozzle. With the help of cold pulling, it is easier to clean the nozzle with Nylon filament. Just let the debris attach to the filament. Once, nylon is partially cooled, pull it through the nozzle head.

The Conclusion

It is always fun to create astonishing prints on your own. And, 3D printing allows you to do that with perfection. With so many choices of materials, the technology enables the printing of precise parts with ease. However, few materials, such as Nylon aren’t that easy to handle.

While Nylon has just the right mix of properties making it apt for a wide array of applications, it does come with a few challenges. Those wanting to work with this material must have the required skills to do so. Or else, the parts may not be suitable for the jobs, they are intended to go with.

But all these hurdles can be crossed by simply making yourself acquainted with the print settings and probable issues that come along with Nylon printing. Such as, a high melting point of the material requires more than the usual temperature range for extrusion.

Mastering Nylon print temperature will help complete most of the complicated settings of the material. Alongside, you must also consider the other variables such as speed, layer height, and more.