If there is a filament that’s easy to print for beginners, it’s PLA. Made with green renewable sources such as starch, corn, or sugar cane, the Polylactic Acid (PLA) is also environmentally friendly. Not just that, PLA is less expensive when compared to other materials and does not require a heated bed for printing.

Already excited to work with the material? Well, why not first go through the PLA 3D print speed settings to make sure we create the best quality parts?

Given its different perks, PLA is one of the most popular choices for 3D printing beginners. Apart from parts creation, PLA 3D printer filament can be used in the process of prototyping as well.

PLA filament is a common choice in 3D printing and is used in many industries and companies where 3D printing is still a relatively new addition. It is ideal for a group of individuals who are looking to carry out fast prototyping, which is why it’s the perfect choice for quick work.

Moreover, PLA as a flexible filament enables the printing of strong parts. PLA is one of the rare flexible filaments that offers unique physical and mechanical properties. But you need to be very cautious of it and take utmost care, especially in the print speed section.

So, let’s explore the features and advantages of PLA and then finally look at the printer settings that you need to make sure you have while 3D printing with PLA.

Overview of PLA

As mentioned above the PLA material is made from renewable resources, and is completely different from plastics that are petroleum-based. They are made from oil or natural gases that are in shorter supply throughout the world.

Therefore, PLA is such a material that is extremely reliable in terms of availability. It is compostable and that is something that makes it completely different from other types of 3D printing materials.

PLA can break down into natural elements in commercial compost facilities and it is a known fact that, when melting, plastics can pose a risk to health as they release harmful and toxic chemicals. Whereas, contrary to this, this material doesn’t produce harmful toxic fumes when it gets incinerated!

- It is available at low cost.

- Has immense strength.

- Can be easily post-processed.

- Objects printed with PLA can deform when subjected to higher temperatures.

Tips for Printing PLA Print Speed, Temperature, and Other Criterions

It’s important to understand the strengths and weaknesses of PLA filament which will enable you to make the most from this material. For this, you need to take into account the possible issues when deciding to start 3D printing with PLA.

Below mentioned are the points that will tell you how to exactly print with PLA to achieve success.

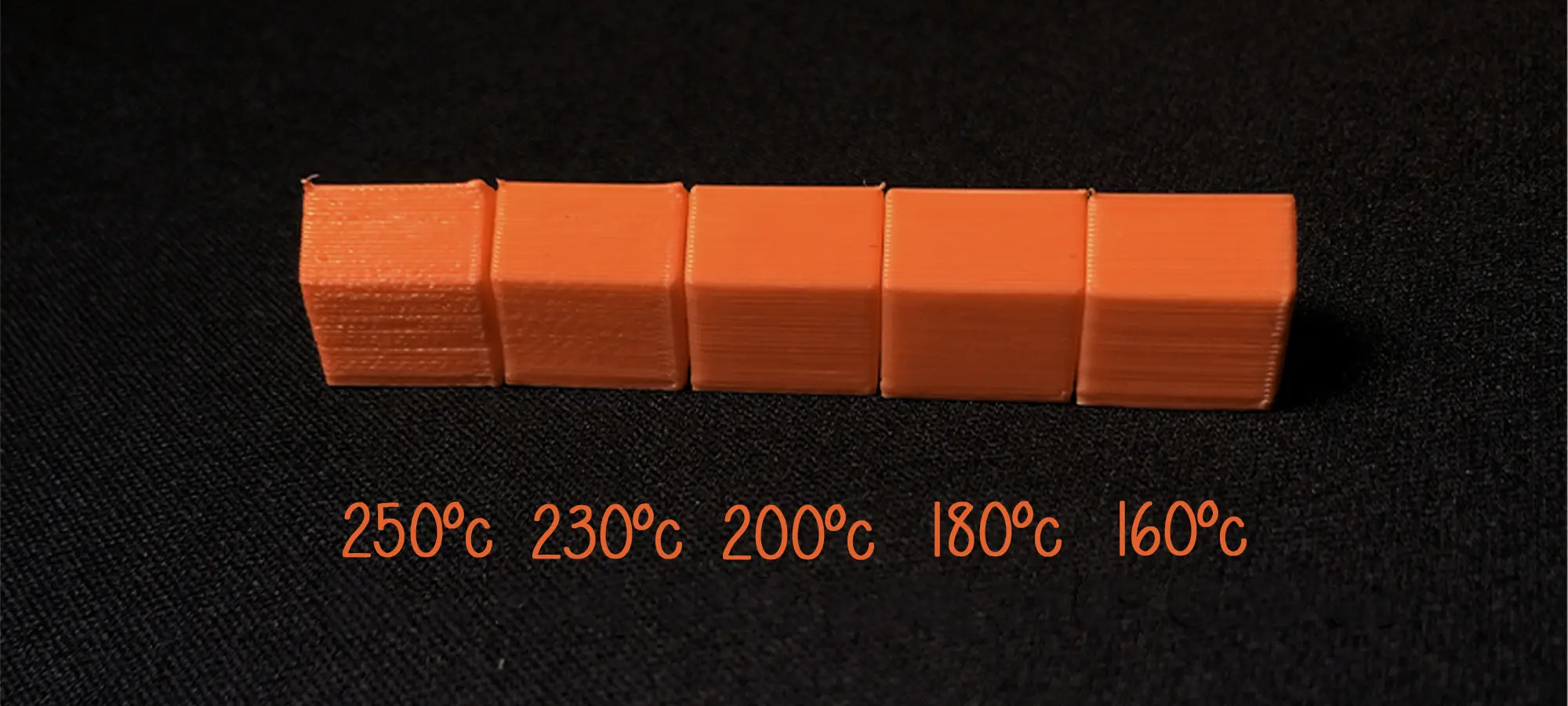

Controlling the Temperature

When printing with the PLA filament it is important that you set the temperature at the right degree. Therefore, experts advise you to begin with a starting temperature of 195 degrees Celsius that will ensure that you give yourself the best chance of success.

The temperature can also be reduced or increased by 5-degree increments or decrements to obtain the right quality of print and strength so that they complement each other.

Some high-quality PLA plastics or some brands of PLA filaments can be printed at a lower temperature as they contain a higher level of pure resin with fewer contaminants. For improving the bed adhesion to the build plate, it is important that it is heated to 60 degrees.

The temperature of your printer’s extruder depends on the diameter of the PLA filament that you use and there are two types available in the market i.e. 1.75 mm and 2.85 mm. For them, the temperature ranges anywhere between 180 degrees Celsius to 230 degrees Celsius.

Opting for lower temperatures within this range for filaments with a diameter of 1.75 mm and higher temperatures for the filaments with a diameter of 2.85 mm is generally considered a good practice.

Some experts even recommend starting printing at a temperature of about 180°C and then adjust the temperature if necessary.

Print Speed

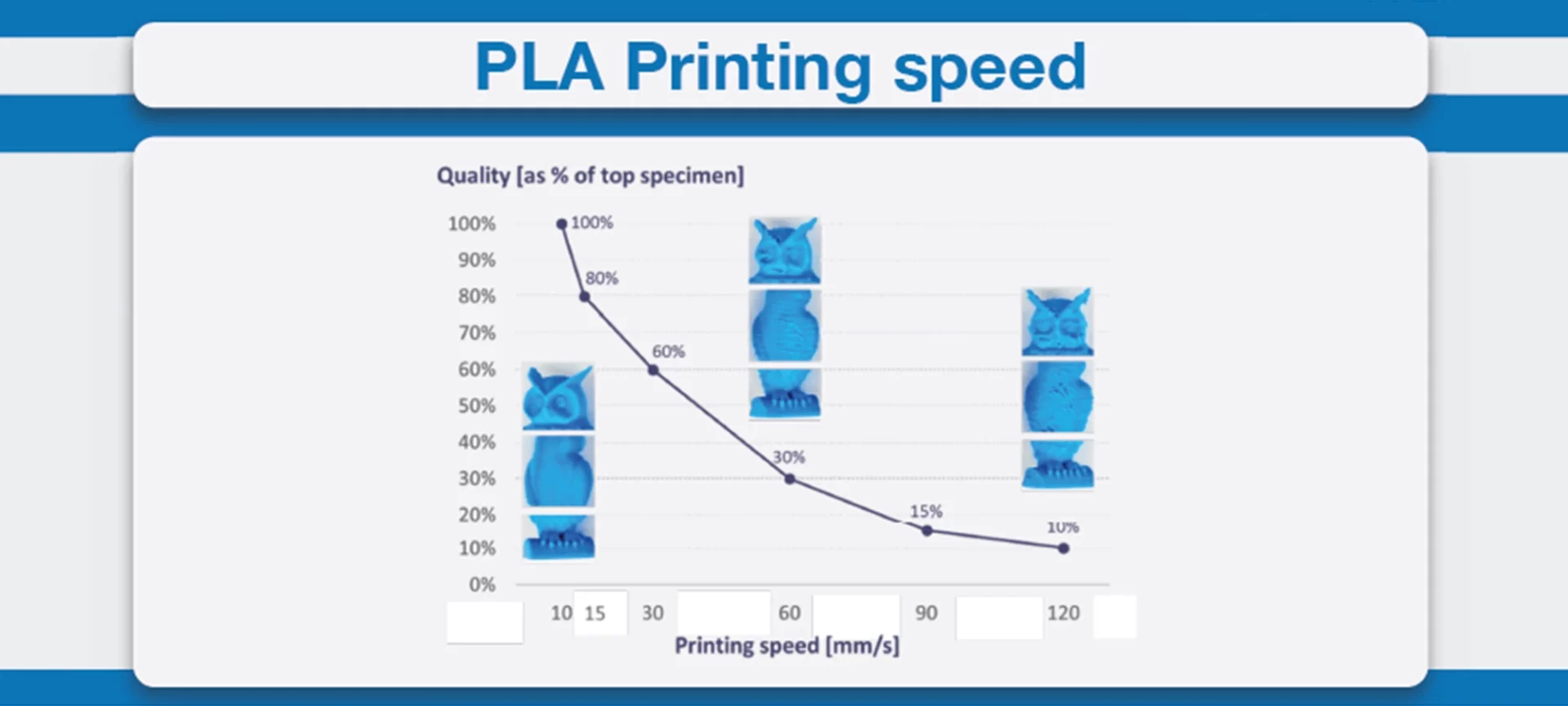

This is the main speed setting that will influence your PLA 3D prints. As the name hints, print speed determines how fast the motors of your printer move, which includes the motors controlling not only the X and Y axis but also the extruder motor. To test for PLA print speed, download the print speed test that’s available online.

What it will do is printing the same shape at gradually increasing speeds, thereby allowing you to visually identify the optimal setting. It is to be noted that too slow of a print speed may cause print deformation because the nozzle sitting on the plastic for too long.

Whereas, too fast and there may be other overheating artifacts caused by insufficient cooling, moreover ringing, under extrusion, and weak layer adhesion. The sweet spot for PLA print speed should be as fast as your printer can get without sacrificing too much print quality.

Print speed can be divided into many more secondary settings such as:

- Outer wall/shell speed: This setting is related to the adjustment of how fast the outermost perimeter of the model is printed. It is typically kept on the lower end to improve surface quality.

- Inner wall/shell speed: This setting is mentioned in context to how fast the inner perimeter of the model is printed and is typically the same as the overall PLA print speed to decrease print times while maintaining print strength.

- Infill speed: This setting adjusts how fast the infill of your PLA model is printed. It’s particularly the same as the overall PLA print speed to decrease print times while maintaining print strength.

- Top/bottom speed: This one is related to the adjustment of how fast the tops and bottoms of the model are printed and are specifically decreased slightly to improve surface quality.

Travel Speed

Travel speed means how fast the printer’s print head moves when it’s not extruding plastic. The general rule goes like increasing travel speed can save significant amounts of print time, but increasing it too much can normally lead to ringing/ghosting artifacts or even misaligned layers and eventually to print failure.

For determining the optimal travel speed for your printer, you need to print out the test print at various travel speeds, starting at 100 mm/s, and go on adjusting by 5 mm/s increments. Keep bumping up the speed until the surface quality is acceptable, and decrease if print quality suffers.

Retraction Speed

For determining the optimal retraction speed for your printer, you are requested to print out the retraction speed test at various retraction speeds. For doing this, you can start with 25 mm/s and adjusting by 5 mm/s increments.

While doing this you can particularly look out for web-or-tree-like strings stretching between the spikes on the model. The perfect retraction speed should ideally be the one that has the highest value minimizing these artifacts without jeopardizing filament flow.

Retract speed: This setting adjusts how fast the actual pulling back of the filament occurs and is usually the same as your overall retraction speed. For tuning it, you need to follow the same process.

Prime speed: This setting adjusts how fast the PLA filament is reinserted after the initial retract, for preparation of further PLA printing. Increasing this PLA print speed will result in reduced print times and less blobbing because of extended exposure of the plastic to heat.

Increasing it to more than an extent, however, may also result in insufficient heating of the freshly-reinserted filament before the actual 3D printing process resumes. For most users, keeping the PLA print speed the same as the general retraction speed setting should work well.

Cooling and Storage

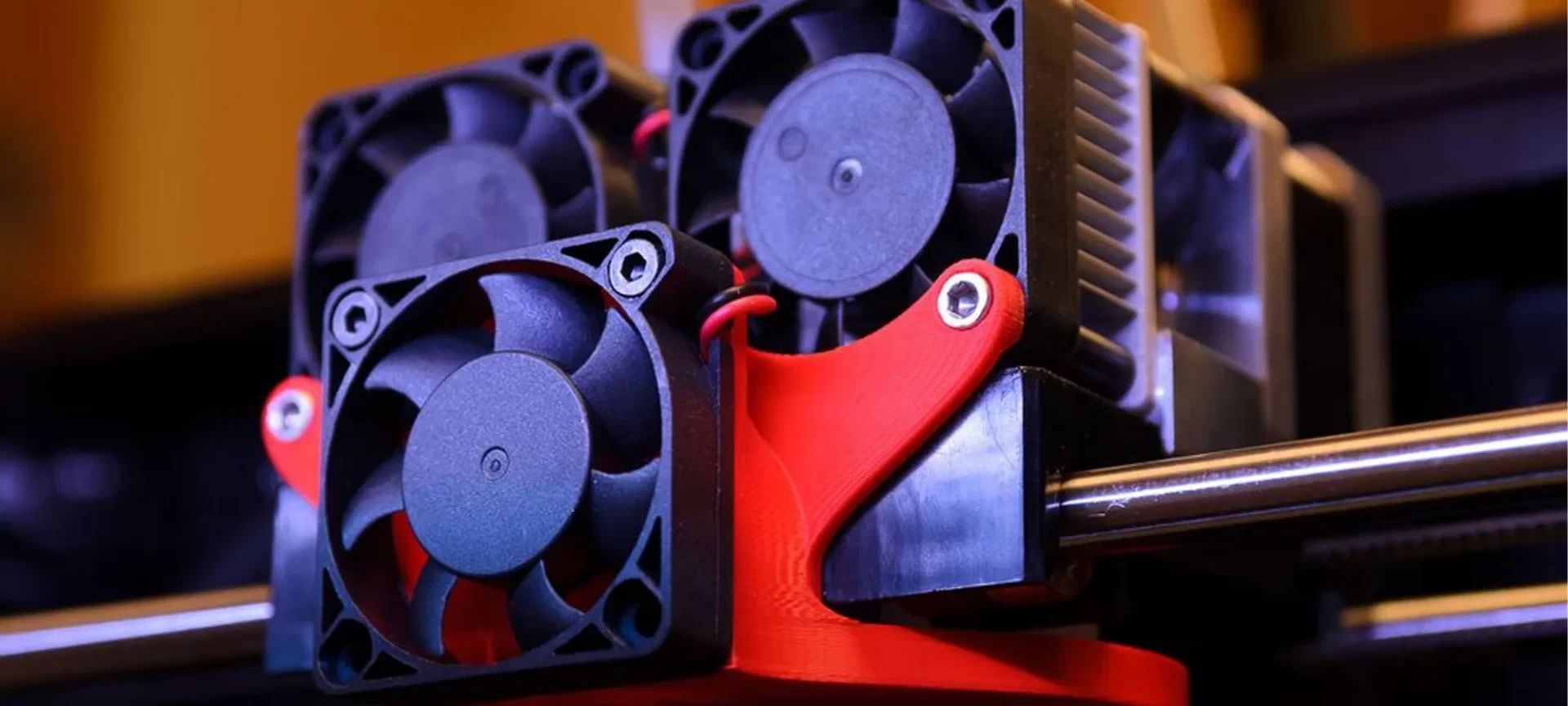

To achieve high-quality PLA printed parts, it’s important to ensure a proper cooling process for which it’s highly recommended to use a part cooling fan for maximizing the power throughout the printing process.

However, during the first few layers of the 3D printing PLA process, cooling can actually affect the layer adhesion of your part that’s going to be 3D printed. For this reason, it is better to turn off your fan for the first initial moments of the printing process.

If your PLA filament is brittle and is forming bubbles during printing, it is likely because the filament is moist due to improper storage. Like ABS,

PLA filaments are also hygroscopic, meaning that they attract moisture from the air. Therefore, it’s crucially recommended to ensure that the PLA filament is stored in an airtight container.

The Conclusion

The above mentioned are the overall PLA settings that you need to take care of while printing with the filament. And, do not forget to take extra precautions when working with PLA print speed settings to ensure high-quality prints. Otherwise, you may have to deal with problems that are most frustrating. So, find out the best settings for your printer before you make your first move to print parts.