Filter

Showing 211–240 of 285 results

PROS:

- High print speed.

- Good quality of parts and functional prototypes.

- Allows printing with Nylon.

CONS:

- No built-in camera.

- No user interface touch screen.

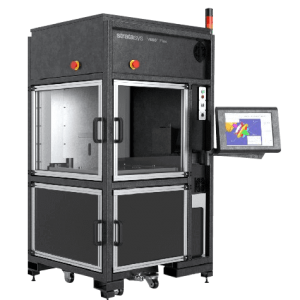

PROS:

- High-quality parts and functional prototypes.

- Good print speed.

- Inert printing chamber.

CONS:

- Comparing the price of this printer and the build volume it offers, you may think that there are other printers that offer even more build volume than this one at the same price.

PROS:

- Inclusion of twin 400W or 700W fibre lasers

- Usage of quad overlapping laser processing

- Closed-loop handling of powder material

- Access for Integrating lasers independently as well as in parallel

- Reduced production cost for high volume metal parts. At the same time-saving material

- Improved gas flow and recirculation

- Enhanced Print Speed

- Open software architecture and customizable system parameters

CONS:

- Leftover powder overbuild platform after 3D printing

- Limited for medium-sized parts printing

- Post-processing required for support removal

- Not feasible for individual or company usage

PROS:

- The built volume of parts and functional prototypes is huge.

- The printer can print with multiple materials.

- It comes with a permanent filter.

- Multiple parts of this printer can be monitored at various times to see whether there is something wrong going on in the printer during the printing process.

- The printer is very much preferable for the mass production of parts and functional prototypes.

CONS:

- Users who are used to finding an even bigger build volume than this printer printed in a printer that costs lesser than the printer are bound to find this printer expensive.

PROS:

- Provides 3 modules in one machine

- Very affordable

- Heated bed

- Print quality is decent

- Expandable laser power

CONS:

- Limited build space

- Noisy

PROS:

- High resolution for printing with 5000 dots/inches

- Easy operation with a one-touch feature

- One can print highly accurate designs

- Soluble support offering hands-free post-processing

- Easy workflow from design to investment casting

- Can work with a variety of metals

CONS:

- Only available for Windows OS

- Expensive

PROS:

- Easy to setup

- One-touch operation

- Auto fault detection

- Auto calibration

- High precision and accuracy

- Larger material tank for continuous operation

- Dissolvable support

- Possible to create complex geometries

- Responsive customer support

- Clear burnouts

CONS:

- Expensive. Not suitable for small business because of affordability

- A bit heavy

PROS:

- Compatible with multiple materials for your 3D printing project.

- Has an ultra-durable resin tank.

- High production rate.

- Top quality lenses ensure dimensionally accurate parts.

- Dependable, high resolution producing projector.

CONS:

- The build volume offered by MoonRay S falls shorter than most basic desktop level FDM or SLA 3D printers.

- Although offering small build volumes, the printer is on a higher end of the budget.

PROS:

- Decent prints with PLA

- Interchangeable nozzles

- Affordable

- Easy to follow guide

CONS:

- Manual bed leveling

- Needs assembly of components

PROS:

- Faster printing of parts and functional prototypes is possible using the printer.

- Excellent quality of pottery enables its user to do a small business of these parts.

CONS:

- Temperature generation, while the printing process will start, is an issue.

PROS:

- Industrial-grade 3D printer, yet affordable.

- Reliable company.

- Detailing about the printer is mentioned on its website.

CONS:

- Not affordable for home users or makers. Specially designed for businesses.

PROS:

- Mass production.

- Good print speed.

CONS:

- Need support structures.

- The quality of parts is average.

PROS:

- Huge build volume.

- High-quality parts and functional prototypes.

- Printing with multi-material.

- Colored printing is a completely new concept that this printer brings into the field of 3D printing.

- High accuracy for printed models

- Users can print highly detailed geometrical models with ease

CONS:

- Highly expensive

PROS:

- Excellent print speed.

- Capable of batch production of quality aligner parts.

CONS:

- Specifically used for the dental industry.

PROS:

- High-quality tissues can be a printer.

- Color quality like no other can be produced in parts using this printer.

CONS:

- If there were more photographs on the website of the parts and functional prototypes printed by the printer, that two, it would have easier to guess the print quality.

PROS:

- Objet Eden 260VS is a cost-effective solution to the needs of 3D printing.

- Using this printer you can create parts and functional prototypes quickly.

- Designers can do functional testing before the final product.

CONS:

- The cost of the printer, seeing the build volume is more than SLA or FDM printers.

PROS:

- Print Area.

- Print Speed.

- Allowing to print without support structures.

CONS:

- Affordability. Not suitable for a lot of small businesses as well apart from the home users.

PROS:

- llows printing with more than 1000 material options.

- Printing parts with colours is possible.

- No post processing needed for 3D printed parts.

- Compatible with a user-friendly GrabCAD print software.

- Quality of parts is unmatched.

- Parts exhibit high quality and smoother surface finish.

CONS:

- PolyJet 3D printing is a complex process, even for professionals. Hence, Objet 500 Connex3 demands skills and attention for its operation. You may also need the training courses offered by the company. In short, the technology has a steep learning curve.

- The printing system demands huge one-time investment.

PROS:

- In giving out the complete details about the printer, the company excels.

- The limitation material is lifted and you as a user, can print with more materials using this printer than others.

CONS:

- Heavy. But what else can you expect from an industrial 3D printer with high print volume?

- Expensive

Best price

PROS:

- Heated glass bed in the printer makes removing objects easy, also ensuring a consistent print surface.

- Contoured large knob guarantees perfect leveling of the printer which minimizes user input making evening out the bed less difficult.

- Massive print area makes it possible to print tall or wide objects.

- The electrical component of printer houses wires and power generator against the frame which gives them more stability.

- Durable, metal frame will not warp and provide immense strength to the printer to keep it away from moving when printing at top speed.

- Gantry-style structure of the printer keeps the print area open while printing large objects.

- Sunlu S8 is equipped with power interruption sensors.

- XYZ stops prevent the entire unit from hitting the ends of the frame, thereby disrupting evenness.

- If the filament that you are using for 3D printing parts or functional prototypes is missing or broken, you get an alert.

CONS:

- Some 3D printed objects may turn out brittle. This may happen especially when creating intricate objects using Sunlu S8.

- The printer is loud, as reported by some users and causes a metallic ring as it operates.

PROS:

- Considerable build volume.

- Extraordinary surface finishes.

- Remote monitoring and control.

- Huge memory space.

- Heated vat.

- Compatible with multiple resins.

- LCD touch screen user interface.

CONS:

- Bison 1000 does not offer simple operation. Uses must possess some technical expertise for smooth operation.

- The printer is on the higher end of the budget than normal DLP 3D printers. Hence, users must invest a large sum in the beginning for purchasing this machine.

PROS:

- Affordable

- Manual as well as Automatic bed Leveling Available

- Proximity Sensor

- No Flex Z Gantry

- Reliable

- High print quality

- Multiple material support

CONS:

- Limited Build Space

- Not quite enough

- Lack of proper bed adhesion

PROS:

- Easy to carry. Highly compact.

- Automatic bed leveling

- Separate Filament Caddy

- HEPA filter

- Blackout Resume

- Filament detection

- Enclosed Frame

- Affordable

- Reliable

- 1-year warranty

- Responsive customer support

- Print beds are swappable as per the filament need

CONS:

- Manual isn’t sufficient enough

- Smaller build volume

- Absence of SD card

- Non-expandable filament caddy

PROS:

- Automated calibration

- Automatic detection of materials

- Affordable

- HEPA and Carbon Filter

- Enhanced print quality

- Different build plates for standard and flexible materials

CONS:

- Small build space

- Software is basic

Best price

PROS:

- LCD touch screen interface.

- Can connect via web browser as well as application.

- make.toys has simple-to-use web interface

- Decent print quality.

- Above-average print speed.

- Compact and flexible design.

CONS:

- Compatible with only one 3D printer filament.

- Thick layers are visible on the print’s surface.

PROS:

- The Delta type construction of T1250 enables you to print with much higher speed than Cartesian type 3D printers of the same price range and features.

- The automatic bed leveling feature of this printer allows you to lessen human intervention and effort, thereby increasing the overall efficiency of the 3D printing process as well as saving time.

- The printer comes equipped with a heated build plate which would mean that you’d get a head start in heating. This would be very helpful while in mass production.

- Seven-inch long touch screen multilingual user interface makes your overall interaction with the 3D printer than otherwise. You are able to relate to the most technical parts of the printer in the most non-technical way.

CONS:

- Being an FDM 3D printer, the print quality of Tractus 3D T1250 is average. There are printers available in the market that will offer you a much higher print quality by spending almost the same or a little bit more price than this 3D printer.

PROS:

- Huge build volume.

- Excellent print speed.

- High-quality parts and functional prototypes.

- Capable to bring various ranges of layer resolutions on parts and functional prototypes.

- Can fit through any normal door.

- An industrial 3D printer that can also be used at your home or office.

- The nozzle can withstand high temperatures.

- Printing bed can withstand huge temperatures.

- Automatic bed leveling.

- Capable of 3D printing with various materials.

CONS:

- No touch screen interface.

- Nozzle gets clogged and needs to be cleaned and maintained on a regular basis which becomes frustrating while mass-producing.

PROS:

- Able to print with many materials.

- Can print parts and functional prototypes of layer resolution starting from 50 microns to 1200 microns.

- Offers a huge build volume.

CONS:

- The printer does not have the Cartesian mechanism of 3D printing. Manufacturing parts and functional prototypes with Delta mechanism has its own inherent flaws and is not able to give out the amount of print quality that’s possible in Cartesian one.

PROS:

- Huge Build volume and high accuracy at an affordable price.

- Closed chamber, high rise in temperature quickly.

- Fast print times.

CONS:

- To know the exact price, you need to request its quote.

- Software information is not specifically mentioned. You need to search for this information.

- Apart from the claims, and layer resolution, you do not get to see a single photograph of part or functional prototype printed by this 3D printer to judge its quality.

PROS:

- Automatic bed leveling enables you to lessen the overall human intervention with the 3D printer, thereby increasing the overall efficiency of the printing process.

- Ability to print with various 3D printing materials allows you to make parts and functional prototypes that find applications in various industries.

- The print bed of this 3D printer can withstand high temperatures.

- You can print with five different nozzle diameters to achieve different resolution ranges in parts and functional prototypes manufactured using Tractus 3D T850.

- High print speed lets you complete the task of mass manufacturing with ease.

CONS:

- The print quality offered by this 3D printer in parts and functional prototypes manufactured using it is not as good as other Cartesian 3D printers.