Compare 3D Printers and 3D Scanners Offers

Best place to find additive manufacturing equipment for beginners and professionals. Compare great value prices or get quotes now.

Filter

Showing 1–30 of 90 results

PROS:

- Fab Pro 1000 can produce parts in hours, which other printers take days to produce.

- The materials that you can print using Fab Pro 1000 are a very wide range.

- From start to finish the print process is very simple.;3D Sprint, the slicing software of this printer is very helpful and user-friendly when in use.

- According to the claims made by its company, Fab Pro 1000 produces parts at a 22% lower cost.

- The post-processing of this printer is very easy.

CONS:

- Overall operating the printer could be a little bit difficult if the setup hasn’t been done properly.

- There are reviews available online in which users complain about how complex is Fab Pro 1000 until the first successful printing.

PROS:

- Easy to operate

- Highly accurate and precise parts

- Affordable

- Compatible with almost 30 different resins

- 4 times faster than its competitors

CONS:

- Small build space

- Closed material system

PROS:

- Enclosed print chamber.

- Material flow control system.

- Enclosure.

- Open material base.

- Dual swappable hotends.

- Autocalibration.

- Water-soluble support.

CONS:

- Clogging and oozing are the two main problems reported with the printer.

PROS:

- Real clay in use.

- Direct extrusion of raw material.

CONS:

- The cost of the printer might be an issue for some people.

PROS:

- The printer has an open design, so there is a lesser issue while post-processing.

- The company uses real clay in making and also offers factory-made clay for you to use.

CONS:

- The printer is a little on the expensive side.

PROS:

- Cooling a part or prototype that is printed using this printer won't be much of a problem because of its open design.

- Post-processing of parts and functional prototypes will be easier.

CONS:

- Because of open design, temperature generation is a big issue. And it may lead to higher print times.

PROS:

- Open design.

- Post-processing is easy.

CONS:

- Temperature generation is an issue.

PROS:

- Scara V4 has an open design, so there is a lesser issue while post-processing.

- The company uses real clay in making and also offers it to its customers. This is a factory-made clay for you to use so that increases the overall quality of parts and prototypes manufactured by it.

CONS:

- The printer is a little on the expensive side. So, if you are a small business owner you may not find it as affordable as you may other printers.

PROS:

- The cooling of the printer won't be much of a problem.

- Post-processing of parts and functional prototypes will be easier.

CONS:

- Because of open design, temperature generation is a big issue.

- Print time is more than that taken by a printer with an enclosed design.

PROS:

- Matrix touchscreen.

- Air cleaning system.

- Thermal management.

- Build size.

- Multi-material printing.

- Water solubility support compatible.

- Auto-leveling.

CONS:

- Weight of the printer.

- The exclusivity of the software.

PROS:

- Excellent precision in even small manufactured parts.

- Parts find application in more than one industry.

- Smart positioning system technology.

- Open material system allowing you print with more than 380 materials.

CONS:

- Small build volume.

PROS:

- Dual extrusion system.

- Multi-color 3D printing.

- Display screen.

- Heated build plate with glass material.

- Hotend with PTFE tube lining.

- Automatic bed leveling.

- High print speed.

- Huge build volume.

CONS:

- Removal of already 3D printed parts is quite difficult with Atom 2.5 EX.

PROS:

- Plug and play operation.

- Wide selection of resins.

- Out of box 3D printing in 15 minutes.

- Fastest DLP 3D printer.

- Reduced post processing.

CONS:

- You will have to figure out ways to manufacture big build volumes as the printer cannot offer more than 96 mm * 54 mm * 127 mm.

PROS:

- Works of different modes.

- Can produce parts with large build volumes.

- Wireless printing.

CONS:

- Closed print chambers are known for giving a difficult time to the user while post-processing.

PROS:

- Huge build volume.

- Independent dual extrusion system.

- High-quality parts and functional prototypes are assured.

- Excellent print speed in batch production.

CONS:

- Difficult post-processing.

- The enclosed print chamber makes the printer susceptible to a lot of maintenance.

PROS:

- Excellent in batch production.

- Produces high-quality parts and functional prototypes.

- Independent dual extrusion system.

- Huge print volume.

CONS:

- Difficulty in post-processing of parts and functional prototypes because of the enclosed build chamber.

PROS:

- Independent dual extrusion system.

- Passively heated build chamber.

- Enclosed body.

- Safety filter.

- Huge build volume.

CONS:

- Post-processing of the part or functional prototype manufactured on the printer is difficult than it is in an open-bodied 3D printer.

PROS:

- Printing in five different modes.

- A storage capacity that has no moisture.

- Huge build volume.

- High-quality parts and functional prototypes.

- HEPA as well as Carbon filter ensuring completely safe part or functional prototypes.

CONS:

- Enclosed chamber.

- Difficult post-processing.

PROS:

- The printer is comprehensive yet simple calibration is magically possible.

- Sigma R 19's print performance is like no other in a similar price range.

- The modes duplication and mirror amplifies your productivity.

- The hotend level correction which is meant to be done mechanically is made easy by the manufacturer's edge in this printer's design.

- The printer does not require enough maintenance in the longer-term because it comes with guides and accessories to support you.

CONS:

- When it comes to filament, the printer is known to produce a lot of waste.

- You need a lot of adhesives while using the printer for the prints of the parts or functional prototype to stick to the print bed.

- Although the manufacturer boasts about the dual extrusion printing done by the printer, the reality is, it works slow.

- A scrap of the final part or functional prototype can escape into the display screen of the printer causing damage.

- During the printing process, the Sigma R19 is noisy.

PROS:

- Dual feed extruder lets you play with color and materials like no other.

- Good print speed.

- Huge build volume.

- Pre Heated build plate.

CONS:

- The price of this printer might be a concern for beginners.

PROS:

- Huge build volume.

- Dual feed extruder.

CONS:

- Enclosed design.

- Post-processing takes time.

PROS:

- Dual feed extruders.

- Automatic bed leveling.

- Closed heating system.

- The door only opens when 3D printing is paused or stopped or not happening at all.

- Huge build volume.

- UPS system.

- Touch screen interface.

- Heated print bed.

- Simple and standard design.

CONS:

- Although the design of this printer makes it comfortable to be used at spaces like offices and education, even at home, whether the users can afford it? Is the question that we do not have an answer to!

PROS:

- It offers a pretty large platform

- It has three different extruders

- By ensuring smart settings and design, the printer enhances the ease of use to the next level

- Support for a wide range of filament materials

- Wired as well as wireless connectivity available.

- High printing speed

CONS:

- The 3D printer is costly and isn’t affordable to all

- Few challenges with precision if the settings parameters are not adjusted properly

- Support for only proprietary filaments

PROS:

- The print speed of this printer is very fast compared to the print speed of other printers in the same price range.

- It offers high print temperatures because of which printing with materials that do not melt at low temperatures is possible.

- Delta Wasp 20 40 Turbo 2 is robust and reliable. It won’t vibrate or make a lot of noise during printing.

- Dual Extruders are optional when printing with this printer.

- The manufacturer of this printer has given freedom if a user wishes to print using third-Party filament support.

CONS:

- The price of this printer could seem expensive to the beginners. It is much expensive than the DIY kits

PROS:

- Easy two-step processing.

- High-quality parts.

- Designed for office.

- Software controlled smooth workflow.

- Straightforward hardware.

CONS:

- Dekstop Metal Studio System 2 is meant for those who can afford a huge one-time investment. So, only for industrial manufactures interested in building high quality metal parts on demand.

PROS:

- Auto Calibration

- Moving print bed

- Accuracy and detailing in minute parts and their edges

CONS:

- Resin bottles are to be bought from the company

- The price of the printer makes it look un-affordable to the experimental beginner in the field of 3D printing

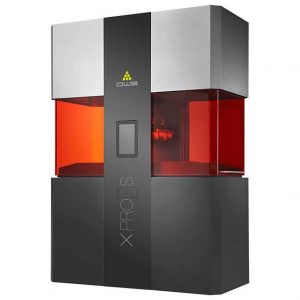

PROS:

- This printer's company is a leader in making additive manufacturing technology 4.0.

- Compatible with a wide range of DWS proprietary resins.

- Has the ability to produce transparent materials, nano-ceramic materials, and materials that are used to make investment casting models.

CONS:

- It is a single laser system.

- Post Processing Requirement.

PROS:

- Offers you printing with a lot of printing materials.

- You can print with four different build sizes and four different voxel preferences using P4K Series.

- The quality of parts manufactured using the printers is excellent.

CONS:

- The build size of parts and functional prototypes is very small.

PROS:

- It provides 10 times faster speed than other DLM machines

- It provides high-resolution printing

- Plug-and-play technology helps in easy operation

- The user-friendly interface provided with the screen touch system for ease of setting the printing parameters

- Compact and can be accommodated in small space as well

- Reduced need for the support structure

CONS:

- It is expensive

- Not accessible for those with low budget

- Post-processing requirement

PROS:

- Capable of creating the most complex parts.

- No debinding is required.

- A furnace was built for the office.

- Two-step bound metal printing process.

- Allows users to print any part thickness.

CONS:

- The printer and sinter furnace are two different machines, managing both of them can be quite difficult even for professionals.

- The cost of the printing machine is a lot on the higher end.