Among the few things on which FDM 3D printing of an object is dependent, 3D printer filament is the most important.

A standard 3D printing procedure starts by making a 3D design file using a 3D design software, proceeds further by uploading it on your 3D printer, followed by filling 3D printing material in the printer, and then pressing the print button should lead to an outcome.

Since the invention of FDM 3D printing technology, different kinds of 3D printer filaments have been invented and come into use. And the inventions still keep on happening.

In this article, we have listed down three different categories of best 3D printer filaments. We start with the most popular ones, followed by fancy ones, ending with professional 3D printer filaments.

The Most Popular 3D Printer Filaments

I say the market of FDM 3D printers is a hundred percent, then the list that is mentioned below can be used in at least 90 percent of the FDM 3D printers.

PLA

It is an abbreviation for polylactic acid. There is constant competition between this 3D printer filament and the next one on this list.

Sometimes PLA gains an immense amount of popularity, the other time, the next one on this list does.

Reasons why people prefer PLA:

- PLA is an easy material to print parts and functional prototypes. Even if your 3D printer can withstand a lower temperature than the next one on this list, you will be able to 3D print PLA.

- PLA does not warp easily, it does not require a heating bed, and also does not give out any strange odor that makes it unbearable for a person to stand near the printer after part or functional prototype has been printed.

- This 3D printer filament is available in many colors and styles, and also in amount.

- PLA is made from biodegradable thermoplastic hence it is more environmentally friendly than other filaments, which are not.

Basic Printer Setting while using PLA: The print temperature for printing PLA is 180 to 230 degrees Celsius, whereas the print bed temperature range is 20 to 60 degrees Celsius.

Application: Models, low-wear toys, prototype parts, and containers.

ABS

This is an abbreviation for Acrylonitrile butadiene Styrene. If you know the LEGO bricks and have seen them, you have felt this material. ABS is also used in making bicycle helmets.

Reasons why people choose ABS:

- Parts and functional prototypes made from ABS are highly durable, and they have the capacity to withstand high temperatures.

- It does undergo a little bit of warping, but not of the level that cannot be manageable.

- Also, ABS if this 3D printer filament is not carefully printed into parts and functional prototype there are chances of it developing intense and potentially hazardous flame. But when printed with a heated bed and a well-ventilated place or with an enclosure, ABS prints well.

Basic Printer Setting while using ABS: The print temperature range while printing parts and functional prototypes using ABS is 210 degrees Celsius to 250 degrees Celsius. Whereas your printer’s print bed should be capable of withstanding 80 to 110 degrees Celsius temperature.

Application: Phone cases, high-wear toys, tool handles, automotive trim components, and electrical enclosures.

TPU

This is an abbreviation for Thermoplastic Polyurethane, it is a typical variation in TPE which stands for thermoplastic elastomers.

This 3D printer filament is popular in the field of 3D printing materials because of being more rigid than normal TPEs.

Reasons why people choose TPU:

- The filament is more rigid and hence it is easy to print in an FDM 3D printer.

- TPU is more durable than most other FDM 3D printing filaments.

- It can retain its elasticity even in cold environments.

Basic Printer Settings while using TPU: The printer temperature range while printing parts and functional prototypes using TPU is between 210 degrees Celsius to 230 degrees Celsius. Whereas the printer’s print bed should be able to withstand 30 to 60 degrees Celsius.

Application: Toys, phone cases, and wearables.

Fancy 3D Printer Filaments

Below mentioned are those filaments which are known to produce good surface finishes in parts and functional prototypes that are manufactured from them.

Other than 3D printing, when a product is made out of these materials, we love it. And so the researchers have also tried to use this in making filament and hence making a part or functional prototype out of it.

They are also known for possessing strength, flexibility, and durability.

Wood

All of us want to feel the texture of wood in most of the parts or functional prototypes that we see around us, don’t we? This 3D printer filament is made of PLA material infused with wood fiber.

Reasons why people choose Wood:

- The first and foremost reason is we all love to see different species of wood around us. We like to see them in the furniture of our place, phone cases, and where not!

- Many types of Wood filaments exist in the market today. The variety of species of wood that these filaments exist in include: Pine, Birch, Cedar, Ebony, Willow, Bamboo, Cherry, Coconut, Cork, and Olive.

- Aesthetic and tactile appeal are the two main reasons why people choose Wood filament over others.

Basic Printer Settings while using Wood:

Do not let your printer generate too much temperature otherwise, your wood will almost burn and lead to a print failure.

The basic shape, as well as the appearance of parts and functional prototypes made from Wood, can be improved by doing a little bit of post-processing.

Ensure that the Wood filament you are using does not cause wear and tear to your printer’s nozzle and use the filament with extra precaution.

Application: Models that are used in architecture.

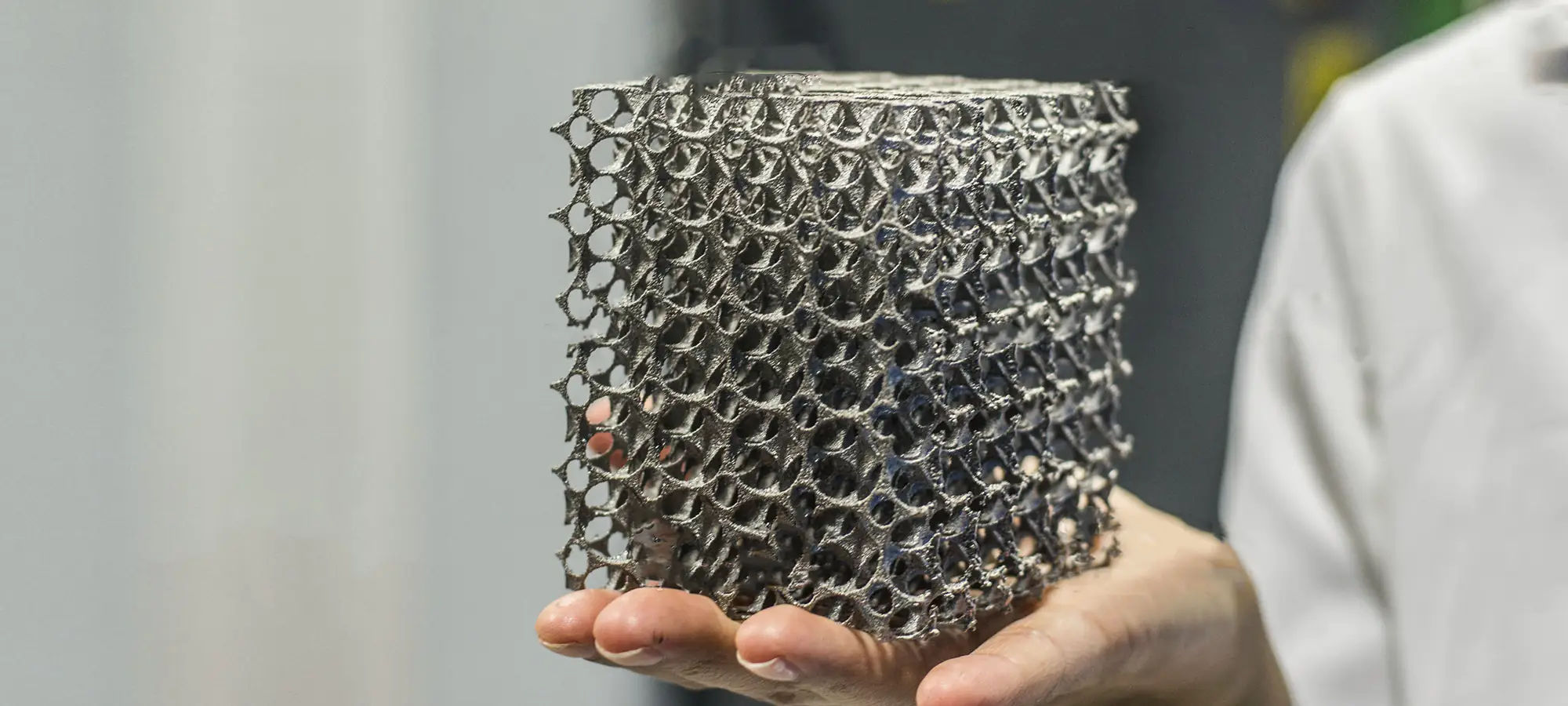

Metal

This filament is for all those who are looking for something bulkier and shinier in the aesthetics of their parts or functional prototypes.

Although this is not completely metal, it is a mixture of metal powder and either PLA or ABS. However, the looks can be often deceiving.

Reasons why people choose Metal:

- As in wood, so in metal, people’s eyes are fully used to seeing metals such as bronze, brass, copper, aluminum, and stainless steel.

- Specific looks that you have in your imagination can be achieved just after a little polishing or tarnishing.

- Although, if you are habituated to print with other filaments, you would have to take care that about the nozzle of your printer, otherwise it may get broken in the middle of a print, as it gets worn out before time while printing with metal.

Basic Printer Settings while using Metal:

As mentioned above, one needs to take care of the nozzle wear of a printer while printing a part or functional prototype using Metal filament.

The common configuration of these filaments are 50 percent metal and 50 percent ABS or PLA, but the percentage of metal can go as high as 85 percent in some filaments.

It depends on the brand that you buy and the company that manufactures that Metal filament.

Application: Tools, Grates, and finishing components.

Biodegradable

As the name suggests, these filaments are the most unique ones on the list till now. The negative impact caused in the 3D printing world by plastic filaments is lessened by using biodegradable filaments.

Reasons why people choose Biodegradable:

- The primary reason for choosing this filament is, as you can guess, it is sustainable material in a field where every other filament damages the environment.

- It can produce a good quality print in parts and functional prototypes manufactured out of it.

Basic Printer Settings while using biodegradable: They should be dealt with with utmost care as they can be damaged easily if not printed using extra care than any other fancy 3D printer filaments. Biodegradable should be used in projects wherein prototyping is a must.

Application: Still being researched upon. As this is a new category that has just emerged out, its applications are still being figured out after experimenting with it in various fields.

Conductive

This filament is specially dedicated to computer and electrical engineers, for making parts and functional prototypes related to their field.

Reasons why people choose Conductive:

- Hobbyist printing projects such as low-voltage electronic circuits can be easily printed by conductive that have carbon particulates in PLA and ABS.

- All one needs to do for printing with this filament is coupling a conductive with ordinary PLA or ABS in a dual-extrusion machine.

Basic Printer Settings while using Conductive: This filament only supports low-voltage circuitry with customized electronic projects. This material is also being researched upon and hence the perfect printer settings have not been generalized and it varies from one brand to the other.

Application: Coupling a circuit board with LEDs, sensors, gaming controllers, digital keyboards, and trackpads.

Professional 3D Printer Filaments

This set of filaments are less commonly seen in desktop 3D printing, as they are more popular with the industrial and commercial side of 3D printing.

Carbon Fiber

Popular 3D printer filaments are coupled with carbon fiber to develop a filament which is an extremely stiff and rigid material with very little weight.

The parts and functional prototypes made using Carbon Fiber filament shine when put into application.

Reasons why people choose Carbon Fiber:

- It has good structural strength and low density.

- Carbon fiber is fantastic when it comes to making parts and functional prototypes of mechanical components.

Basic Printer Settings while using Carbon Fiber: The printer settings depend on the brand of Carbon fiber filament that you are using for making parts or a functional prototype. Generally, the printer temperature range and bed temperature range of your printer should be more than that which you have to set while manufacturing parts and functional prototypes using popular filaments.

Application: Parts of your model car or a plane can be made using this filament.

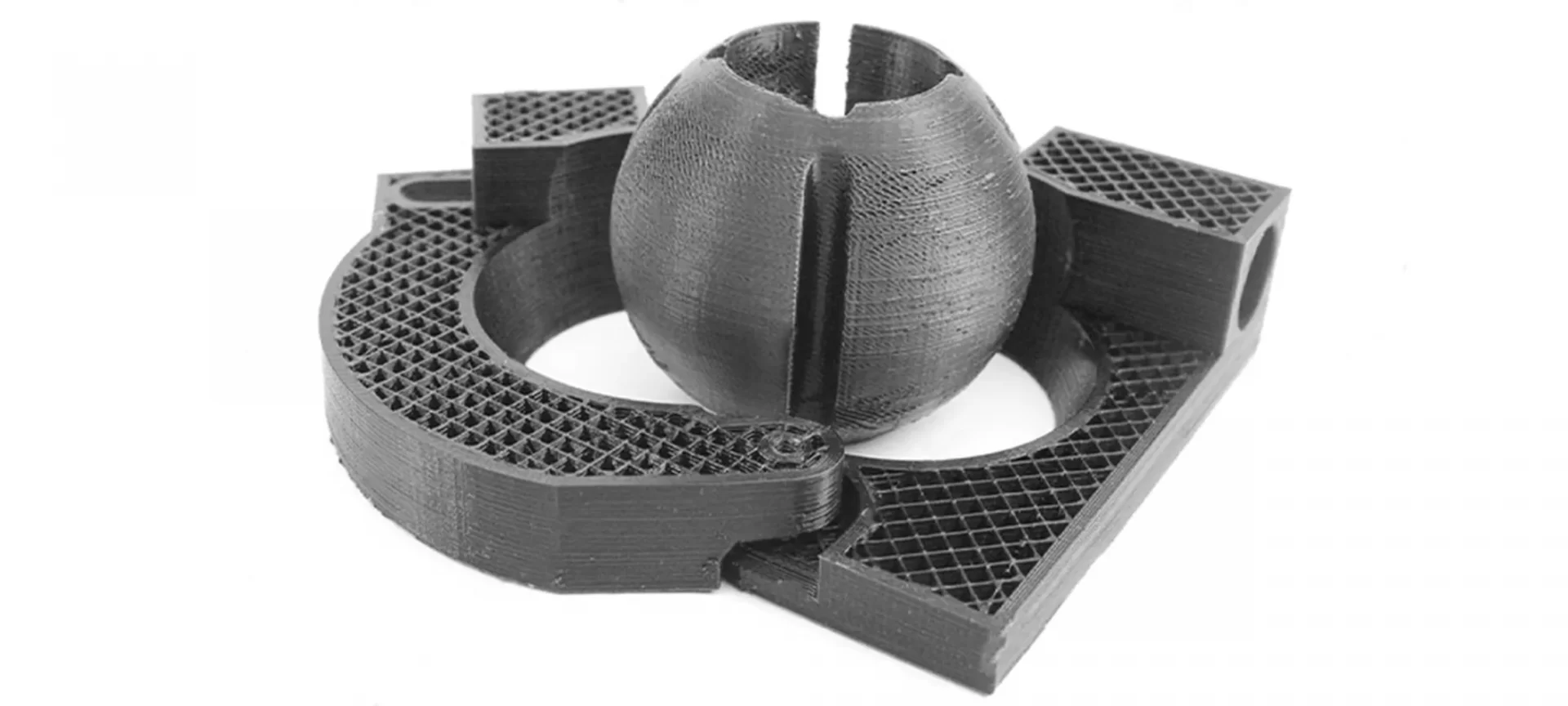

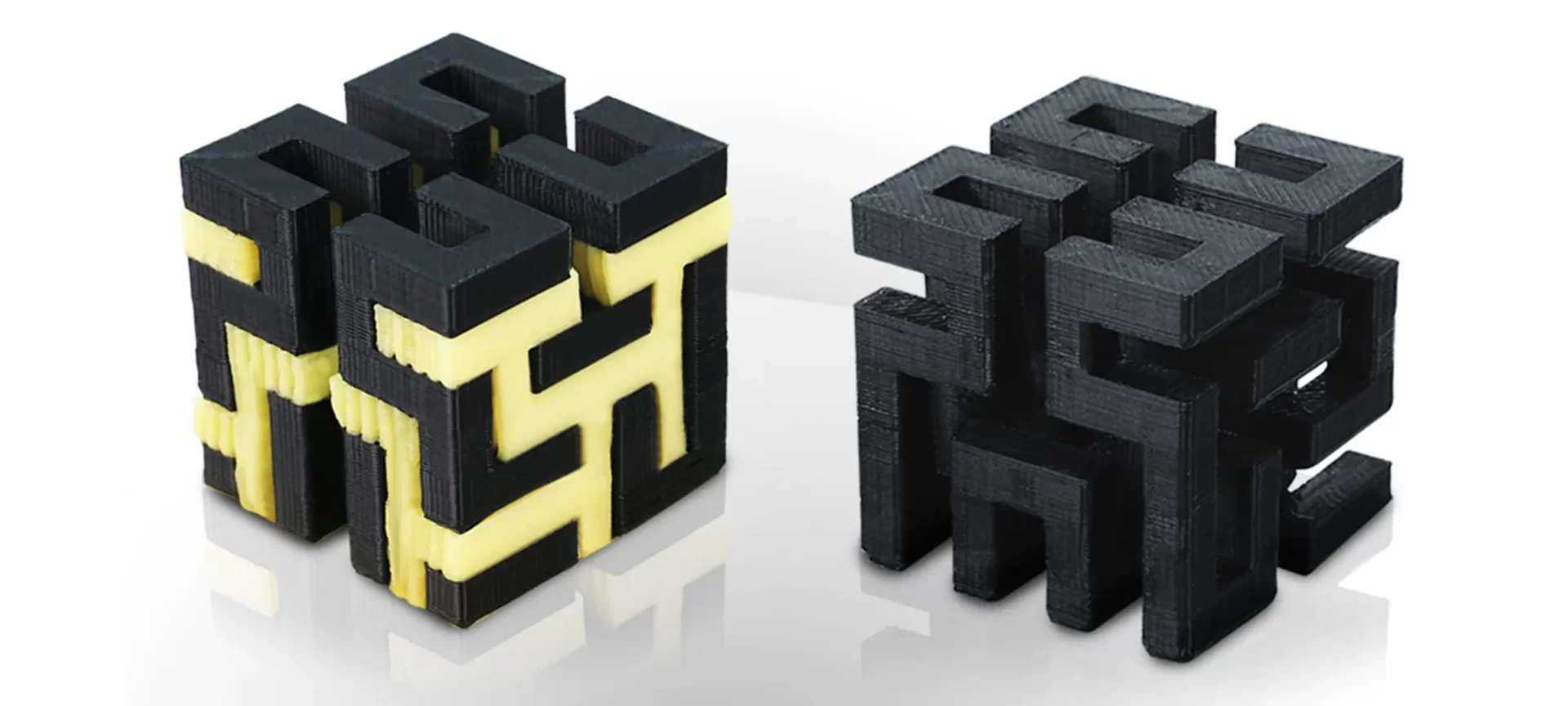

HIPS

This is an abbreviation for high impact polystyrene. As the name hints it is a copolymer of polystyrene and has the elasticity of rubber. You might have encountered it in protective packaging as well as containers.

Reasons why people choose HIPS:

- Overhangs are generally required in making complex parts or functional prototypes, and this is where HIPS steals the show.

- When paired with ABS in a dual extrusion printer, HIPS performs as an extraordinary support material.

Basic Printer Settings while using HIPS:

When you are using a dual extrusion system, HIPS simply cranks the support to the maximum and fills the gaps in your design with the filament.

There is not much in terms of the care that you need to take while printing with HIPS, all the care should be taken in the designing part of the part or functional prototype as HIPS is mostly used for overhangs.

It is stronger than PLA and ABS and hence while printing parts and functional prototypes using HIPS filament, the printer must withstand more temperature than it does while printing with PLA and ABS.

Application: HIPS is an all-rounder that can be used for making all kinds of parts and functional prototypes that need to stand the wear and tear of times.

The Conclusion

While out there in the market to purchase a 3D printer filament, you must consider your 3D printer and the temperature that its extruder, as well as the print bed, can withstand. Another important parameter that plays a role in 3D printing is the glass transition temperature of the 3D printer filament.

The rule of thumb here is also that the characteristics of filament resemble the characteristics of part or functional prototype that you manufacture.

So, you should also take into consideration the part or functional prototype that you are manufacturing as equally as you do consider your 3D printer.

Hope this buying guide leads you to the correct 3D printer filament for your 3D printing project. And lets you print a part or functional prototype that is closest to your imagination.