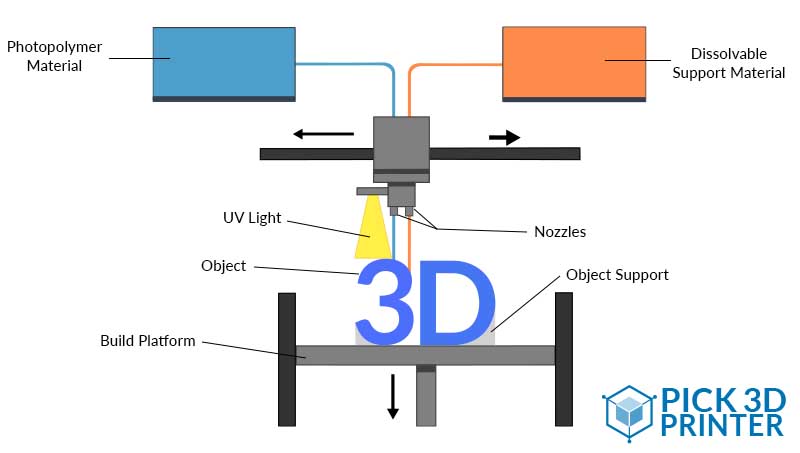

Patented by Objet Ltd. under the name of Polyjet (which later merged with Stratasys), Material Jetting combines Inkjet technology and photopolymerization.

Material Jetting 3D printers provide many advantages like delivering objects with smooth surfaces and excellent resolution up to 0.016 mm. The technology allows users to print with a wide range of materials and colors at a relatively low cost and faster print time.

Material Jetting 3D Printing

Like every other 3D printing technology, the process of material jetting too begins by creating desired object’s design on CAD software. The final design is then cut into several digital images, each one representing a layer of the object with the help of a slicer. Lastly, the STL file is sent to the 3D printer for printing.

The Material Jetting process starts by heating a liquid resin to 30 to 60 degrees Celsius temperature for obtaining an appropriate viscosity for printing.

A print head, like that of an inkjet 3D printer, projects hundreds of micro-droplets of UV light-sensitive photopolymer resin. Later, the resin solidifies to create the first layer of the part. The process is repeated until the printing completes.

Similar to the stereolithography process, material jetting too allows for multi-material and polychrome printing. This is because the printhead hosts multiple nozzles capable of simultaneously jetting different materials and soluble.

- Material jetting 3D printers permit multi-material and multi-color objects.

- The technology is known to produce smooth parts with surfaces comparable to injection molding.

- Objects manufactured by material jetting have homogeneous mechanical and thermal properties.

- Users can easily adjust the properties of the material depending on the outcome they desire.

- Material jetting materials are photosensitive.

- The cost of producing parts with material jetting technology is usually higher.

- Large volumes of parts cannot be printed using this technology.

Areas of Application and Leading Companies in the Market

Material jetting 3D printing technology is very popular among industries wanting to create highly detailed functional prototypes. The technology helps users to come up with finished parts that require almost no post-processing at all.

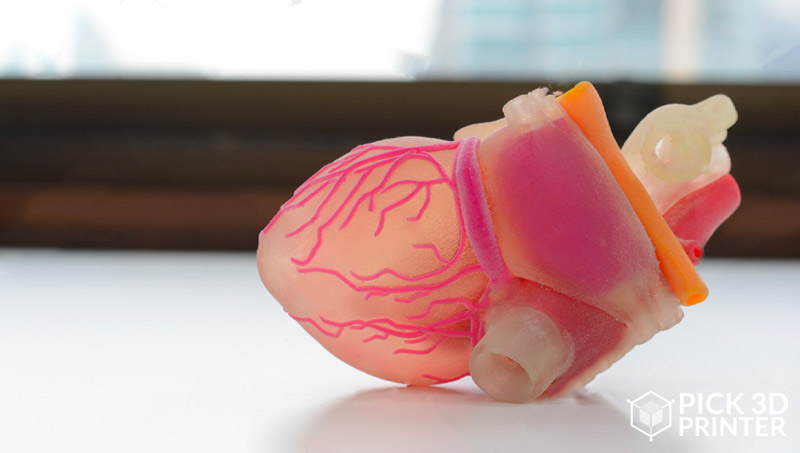

It is very popular in the medical sector for creating anatomical models using different colors. Medical models created using material jetting are also used by doctors to explain patients about their diagnosis. Also, surgeons can use 3D printed models to learn and train themselves for upcoming surgery. Apart from the medical field, material jetting also plays a huge part in art and jewelry making.

As mentioned above, Stratasys is a huge name associated with Material jetting since its inception. Their 3D printers’ series going by the name PolyJet is based on Material Jetting 3D printing technology.

Some of its best-known 3D printers are J750 and J350. Compatible with Pantone colors, these printing systems can print with more than 500,000 colors, textures, gradients, transparencies, and material hardness.

Apart from Stratasys, 3D Systems also offers its range of material jetting 3D printers. Projet MJP 5600 is one of the many names of the company’s material jetting 3D printers. Although not as colorful as Stratasys, the printing system can print different prototypes with elastic or hard materials.

XJet is another company based in Israel that prints parts using nano jet 3D printing – a variant of material jetting 3D printing.

While you already know a lot about the technology by now, it’s time to look at some of the best material jetting 3D printers in the market available currently.

Best Material Jetting 3D Printers

It is very easy to understand material jetting if you have worked with a 2D printer before. Just like the 2D printers jetting drops of ink on paper, the material jetting 3D printers to spray large drops of ink composed of photopolymers on the build surface. These drops are projected by a print head and then hardened by UV light.

Apart from making metal parts, the technique is also used for making ceramics and even wax parts. There are other variants of the material jetting technique. Such as Polyjet, Nanoparticle jetting, and drop on demand. So, let’s begin our list of best material jetting 3D printers.

Stratasys J750

Based on polyjet 3D printing technology, Stratasys J750 is capable of printing up to 6 different materials in a single print with over 360,000 colors available.

The printing system can create human anatomy that mimics skin, bone, and tissue. Not just that, it’s not even expensive to create human anatomy and one can save up to 70 percent when printing using this technique.

Compatible with GrabCAD print software, J750 streamlines job management and permits for pre-validated anatomical applications.

There is hardly another option in 3D printing that offers unlimited possibilities for designing parts with biomechanical properties in full color. This material jetting 3D printer allows 3D printing medical prototypes or models with the most intricate details.

J750 Digital anatomy 3D printer is equipped with three unique digital materials and anatomical pre-sets that offer ultra-realistic anatomical simulation and biomechanical realism. The maximum build volume provided by the printing system is 490 mm * 390 mm * 200 mm.

|

Mimaki 3DUJ-553

Offering a building envelope of 508 mm * 508 mm * 305 mm, Mimaki 3DUJ-553 is based on a UV LED process for making parts and functional prototypes. In this process, a source of UV light is used for hardening different layers successively.

The printing system deposits ink droplets, either colored or black and white on its printing tray until the final object is obtained. This one offers even more color options than Stratasys J750. Users can choose from 10 million colors.

Moreover, it is also possible to add transparency in parts using translucent ink. A major plus point of this printing system is the simulation software that makes it possible to have a precise overview of shapes as well as colors of the part before 3D printing.

In addition, the printer boasts a surveillance camera that permits complete monitoring of the 3D printing process remotely. The machine utilizes a support structure that can be dissolved in water, making it possible for building accurate and clean models without any damage.

XJet Carmel 1400M

The Carmel line of 3D printing systems by XJet relies on the company’s patented Nanoparticle jetting 3D printing technology. Herein, a liquid containing nanoparticles of either metal or ceramic material is used in suspension.

The printer manufacturer offers metal as well as ceramic systems that are available in two sizes. There is a smaller build plate of 700 square centimeters, with the larger one offering 1400 square centimeters.

The larger one is actually the largest build trays in the entire industry. Apart from providing quantity, the printing systems also offer impressive quality prints that are accurate and reliable. Users can achieve the highest level of productivity.

Both the printing systems are compatible with Autodesk and Netfabb software. Moreover, Carmel 1400 M, as well as C, can be synced with a mobile application to ease the overall interaction.

|

Solidscape S390

Dedicated to the jewelry sector, Solidscape S390 is a product of Prodways group. The printing system has two printing heads allowing the users to deposit wax as well as a soluble support material for designing fairly precise molds, whether for injection or for lost wax molding.

S390 provides a printing volume of 52 mm * 152 mm * 101 mm and a wide choice of compatible materials. It automatically generates print media for protecting the most fragile parts of the model that dissolve completely leaving the durable wax models ready for molding.

|

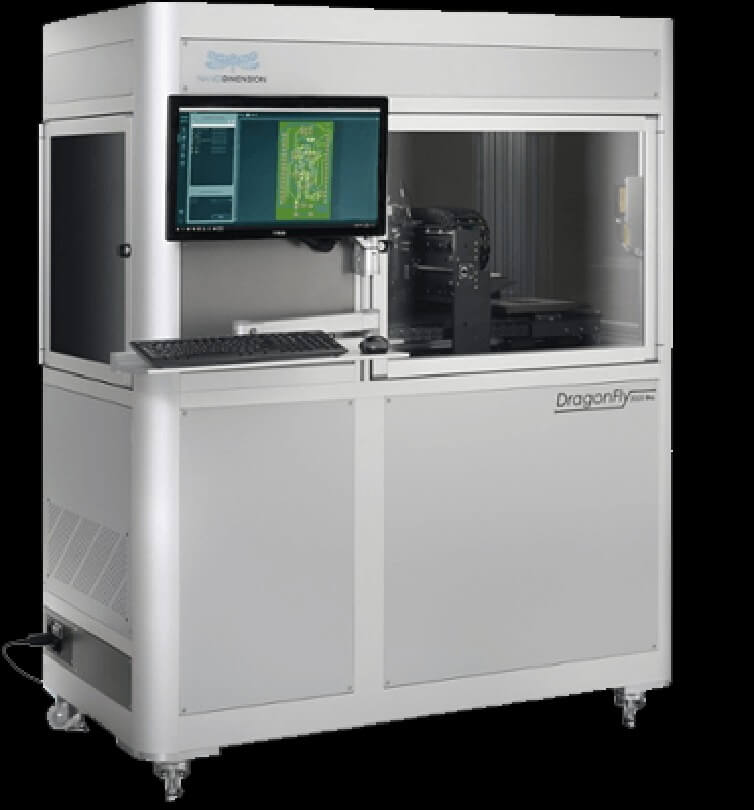

Nano Dimension Dragonfly LDM

Here’s is the industry’s only comprehensive additive manufacturing platform for 3D printing electronic circuitry round the clock. Hosting Nano Dimension’s advanced LDM technology, the printing system allows for unattended operation. Dragonfly is capable of maintaining itself to an extent that it typically needs only one weekly maintenance operation.

All the credit for such flexibility needs to be given to the three major improvements such as: a) new advanced printer heads, b) software management algorithms and c) automatic self-cleaning of print heads. Dragonfly is a large 3D printer offering a build volume of 160 mm * 160 mm * 3 mm.

Capable of concurrently 3D printing using simultaneous multi-materials, Dragonfly offers a minimum trace layer thickness of 17 microns. The parts produced by this 3D printing system are known to be used in aerospace, defense, automotive, medical, and electronics.

XYZPrinting da Vinci Color

Based on the combination of FFF and inkjet 3D printing technology, Da Vinci color is manufactured by the Chinese manufacturer XYZ printing. Its inkjet 3D printing technology utilizes CMYK cartridges allowing millions of color options to be created because of absorbing ink droplets. The printing system is capable of 3D printing with materials such as PLA and PETG filaments.

It offers a build volume of 200 mm * 200 mm * 150 mm and a plane resolution ranging from 100 to 400 micrometers at a print speed ranging between 30 to 60 millimeters per second.

To ease the interaction the printer comes with an integrated touch screen interface. Moreover, assisting users in the removal of parts is a removable printing plate. Lastly, the printer can be connected wirelessly to the home network.

3D Systems Projet CJP 860Pro

This machine is manufactured by 3D Systems – the 3D printer manufacturing giant. It can create a realistic color experience with its five print heads.

The machine’s color jet printing technology allows for building parts that are seven times cheaper compared to other technologies. Also, parts are built with zero waste which is a revolution in itself.

This material jetting 3D printer also eliminates the requirement of supports and therefore reduces the post-processing time. Moreover, it has a faster printing speed, permitting large-format models to be built in a time period of just a few hours.

Overall, the printer is an all-rounder. It not only saves your money but also a lot of time. Above all, it delivers mind-blowing color and has a large build space of 508 mm * 381 mm * 229 mm.

HP Multi Jet Fusion Technology

HP’s experimentation in 3D printing technology deals with its unique multi-jet fusion technology which is a variant of binder jetting technology. The process deposits a binder on the metal powder. But, unlike the usual binder projection technique, herein a second liquid agent has been deposited for refining details as well as surfaces.

After this, the material is heated for making different elements interact with each other and create the final part or functional prototype.

The company has to date launched several 3D printers by the name: HP Jet Fusion 300/500 based on the same technology allowing for printing functional prototypes in black and white. Apart from that, the company also has Jet Fusion 3200/4200 series and 5000 series.

HP 3D Printer Price – How Much HP 3D Printers Cost

Basics About HP 3D printers – Compare, Uses and Features

The Conclusion

Material Jetting 3D printing technology offers accurate parts with excellent surface finishes. Based on powder-based 3D printing technology, it allows users to make parts and functional prototypes with extremely minute detailing and intricacies.

Although it does not offer parts with extremely huge build volumes such as FDM 3D printing technology, the technique can bring some of the most realistic designs to life.

Material Jetting 3D printers generally demand huge one-time investment and therefore are preferred by small or large manufacturers in the medical and jewelry niche.

These printing systems offer simple workflows that have a huge footprint and usually come with two to three units. The main benefit of material jetting is its ability to offer printing with more than one material as well as more than one color.

Thereby, making the parts look almost real. Also, its ability to print final parts requiring no post-processing is unmatched. With all of that, these machines also offer superb print speeds. Hence, if you want to buy a material jetting 3D printer, do not forget to check our recommendations.