Worldwide

Filter

Showing 91–120 of 260 results

PROS:

- Removable build plate

- Quiet operation

- Simple and impressive design

- User-friendly touchscreen interface

- Very Reliable

- Overhead light for enhancing the visibility of prints

CONS:

- Tiny build space

- Non-heated print bed

- Lack of auto-leveling feature

- Only supports PLA

- Tricky when working with support structures

PROS:

- Easy to setup

- Assembled and compact

- Removable Bed

- Assisted bed leveling

- Affordable

CONS:

- No automated calibration

- Only prints with PLA

- Not suitable for professionals or serious users

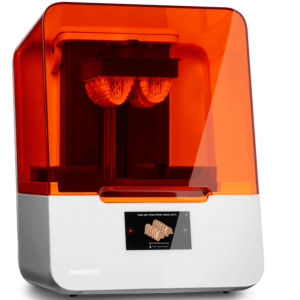

PROS:

- Provides excellent print quality

- Hassle-free setup and first test print

- The combination of hardware and software is amazing, and their tuning is awesome.

- Great slicer software

- Nice user interface

- Relatively noise-free operation

CONS:

- Post-processing is a must for every print.

- Speed isn’t fast when compared to the FDM printers.

- Changing resin is difficult and messy

- Consumables cost such as resin price and tank price are expensive

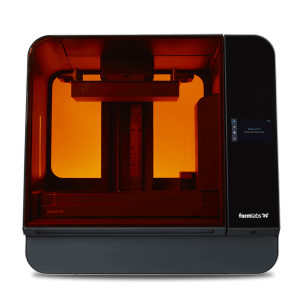

Editor choice

PROS:

- The print speed is fast as compared to its predecessor

- The surface quality is improved

- Controlled monitoring is available

- Price is decent when compared to the other SLA printers

- Advanced SLA technology coined as Lower Force Stereolithography

- Closed body, hence safe

- Good quality prints

CONS:

- Need support structure for prints

- Post Processing Requirement

PROS:

- Easy to learn and operate

- Offers great accuracy and precision

- Compact design

- Auto-generated support

- Light touch removal of support

- High surface quality

CONS:

- A little expensive

- Post-processing required

PROS:

- Produces fine quality orthodontics model without any interruption.

- Minimal cost per part.

- Robust 3D printing system.

- Enclosed build chamber.

- Able to print with biocompatible resins.

CONS:

- Small build volume.

PROS:

- Reduced Peel Forces providing better quality prints

- High-speed printing

- Economical price for an SLA based technology (LFS)

- Automatic bed leveling

- Plug and Play use

- Light support easy to remove;Constant Monitoring

CONS:

- Post Processing Requirements

- Expensive than low prices FDM machines

- Support structure required for every design

PROS:

- Bigger built volume.

- Removable chamber.

- The printer produces amazing prints in parts and prototypes that are manufactured using it.

- It has a layer thickness which is probably the most minimal.

- Available at an affordable price.

CONS:

- Not very fast print speed.

PROS:

- Large build space;2 years of warranty

- Easy to operate with automatic bed leveling

- High-quality prints

- High speed

- Value for money

CONS:

- Missing dual extruder

- The expensive choice for beginners

PROS:

- Large build space

- Automatic bed leveling

- Great print quality

- Fast speed up to 250mm per second

- Sturdy design

- Three interchangeable nozzles

- Remote monitoring through an ethernet connection

CONS:

- Lack of WIFI connection

- Not affordable for home users

PROS:

- Extensive filament options.

- Genuine E3D All metal hotend.

- Massive build volume.

- Industrial Strength Frame.

- Integrated heated bed and BuildTak.

CONS:

- Temperature generation might be an issue due to the open frame structure of the printer.

PROS:

- Highly productive.

- Reduces cost per part by 10 percent.

- Powered by highly effective 4.5 Kilowatt electron beam.

- Capable of mass-producing.

- Amazing design freedom.

- Able to print faster.

- Comes with an efficient PRS-30.

CONS:

- The printer and its components take up huge space so users will have to have a good amount of infrastructure dedicated for this giant piece of industrial 3D printer.

PROS:

- The machine is capable of maintaining powder integrity to ensure optimal part production;

- It features a 100% increase in power as well as 50% faster build times

- Withstand higher heat more than 1000 degree Celsius allowing the incorporation of more alloys

- Allow larger parts 3D printing and more numbers of parts at a time

- Automating most of the processes that needed manual intervention before and providing optimal quality control

- Faster speed and takes lesser time for production

- Increased part printing quality

- User-friendly and simplified processes introduction for operators

- Easy to validate and improvement in the uptime

- Increased efficiency

CONS:

- Post-processing requirement

- Not compatible with plastic or polymer or ceramic materials

- Expensive and huge in size

- Specific to industrial use

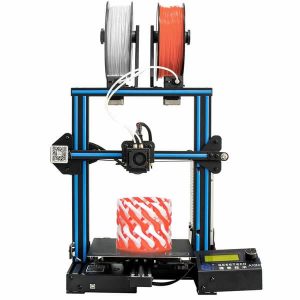

PROS:

- Automatic bed leveling.

- Colour mixer.

- Dual extruder system.

- Filament Sensor.

CONS:

- The printer has an open system because of which temperature generation could be an issue, especially while printing with materials such as ABS.

Editor choice

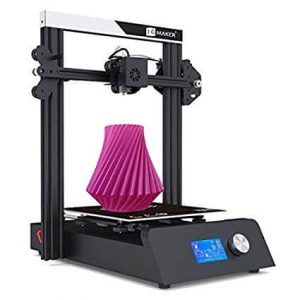

PROS:

- The printer is very compact and easy to manage.

- Accurate and reliable.

- Pre-assembled.

- Provides automatic bed leveling

- Factory calibrated

- It uses the 60W UV LED to process the prints faster.

- The print quality is awesome.

- Offers wired as well as a wireless connection for uploading the 3D models.

- You also get to enjoy the hassle-free smartphone remote control.

CONS:

- The consumable cost is higher. And, this includes the FEP film that wears off with time and regular use. You do get a replacement but aren’t always in the perfect size. You will need to employ extra efforts in cutting the film to the required size.

- Build space is too low.

PROS:

- Delivers quality output.

- Up to 10 times faster at half the cost.

- Delivers fine detail and dimensional accuracy.

- Lets you have accurate thermal control of every layer and enables predictive corrections voxel by voxel for optimal mechanical properties.

- Low cost per part and minimal powder wastage.

- Reduces cooling time which results in faster time to part and more parts ready within the same day.

- Enclosed unpacking and material collection system.

- Automated material mixing and loading systems.

CONS:

- This printing system demands a huge one-time investment which not everyone will be able to pay. And so the accessibility of this wonderful printing technology and the machine is still a huge question.

PROS:

- Automated mixing, sieving, and loading of material

- Plug and Play

- Fast cooling

- External storage tank

- Large build volume

CONS:

- Expensive

- Occupies large space

PROS:

- The 3D printing speed is fast.

- You get accurate 3D printing with fine detailing.

- For 3D printing a part you need no support structures.

- The quality of the part produced is high.

CONS:

- Initial printing investment is higher compared to others.

- You are not able to produce some curved, hollow geometries.

PROS:

- Printing with five different 3D printing materials.

- Post-processing of parts and functional prototypes is easy.

- High-class software solutions.

- Huge build volume.

- Good quality parts and functional prototypes.

CONS:

- The cost of this 3D printer is too high for any beginner to even think of paying it. Even if you are a 3D printing professional you have many other options to deliver a similar range of quality at a much lower price.

PROS:

- Accurate functional parts with intricate detailing.

- Complete coloring of parts is possible with voxel control.

- The speed of this 3D printing system is tremendous.

- You need no support material.

- It reduces waste.

CONS:

- Although the company claims it as a suitable 3D printer for offices as well as domestic use, you can hardly manage the complexities the printing systems bring to your place.

PROS:

- Full metal construction

- Full-color LCD touchscreen

- Filament run-out sensor

- Easy to assemble

- USB stick

- Power off recovery

CONS:

- Produces lots of noise while printing

- Hard to work on

PROS:

- Highly affordable

- Easy to setup

- Multiple filament support

- Heated print bed

- Print resume option (both for a power outage or accidental removal of SD card)

- Acceptable print quality with smoother surface finish

CONS:

- May not suit professionals with much complex print requirements

- No auto bed leveling

- Upgrades are difficult

- Not a plug and play machine

PROS:

- Cloud platform

- Plug and Play

- Many Automated Features like bed leveling and nozzle retraction

- Power Recovery

- Dual Extrusion

- Heated Glass Bed

- Touch Screen Interface

CONS:

- Firmware updated frequently

- Manual Calibration

- Aesthetic looks of touchscreen

PROS:

- Compact

- Plug and play

- Nice resolution at this price

- Heated bed

- Remote monitoring

- Open design is compatible with open source slicing software

- Affordable

CONS:

- The basic version does not have enough feature

PROS:

- Ceramo Two has a build volume that is rarely seen in 3D printers specializing in ceramic 3D printing.

- The print speed of this 3D printer is in talks since its announcement. It is said to be one of the finest 3D print speed ever in the field of ceramic 3D printing.

CONS:

- Lack of proper information regarding the printer is probably something that's going to hinder the 3D printer for a long time.

- As far as features are concerned, people may find this printer expensive.

PROS:

- Removable magnetic build plate.

- Preloaded slicing software.

- Low power consumption.

- Ready to print, pre assembled.

- Fast heating.

- High precision.

- Silent working mode.

CONS:

- Low build volume.

- Printing with PLA only.

- Non uniform heating.

- Irregularities on surface of the 3D printed part.

PROS:

- It possesses independent dual extruders

- Enclosed chamber

- The built-in camera along with the custom Octoprint plugin for enabling remote monitor and control

- Recording of automatic time lapses;7″ touch screen display

- Extruder priming and wiping before every new print use

- Direct filament feeder

- Assisted dual-head calibration

- Enhanced cooling fans setup

CONS:

- Users have reported of filament tangling when spools with too much filament are used

- Times taken for heating is more than 5 minutes

- Manual bed leveling

PROS:

- Dual extruder

- Large print space

- Automatic calibration

- User-friendly User Interface

- High Speed

- Great Precision

- Third-party filaments allowed for printing

- Compatible with a large number of filament type

CONS:

- Expensive

- Not suited for home users

- Bulky

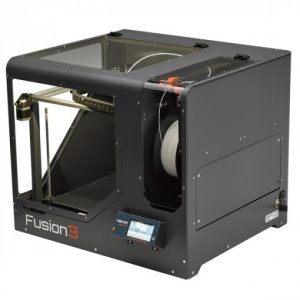

PROS:

- Large-volume

- High precision

- Dual extruder

- Professional grade printing

- Heated bed

CONS:

- Expensive for professionals and home users