Multiple technologies, including FDM, SLS, and MJF, have arisen since Charles Hull invented stereolithography (SLA) in 1984. Digital Light Processing, for example, is derived from SLA. Each of these processes, as you surely know, is designed for a specific industry or application.

Today, we’ll look at SLA and DLP technologies, determining their properties in order to provide a comparison between the two procedures. So, let’s check out our comparison between DLP vs SLA.

What is SLA?

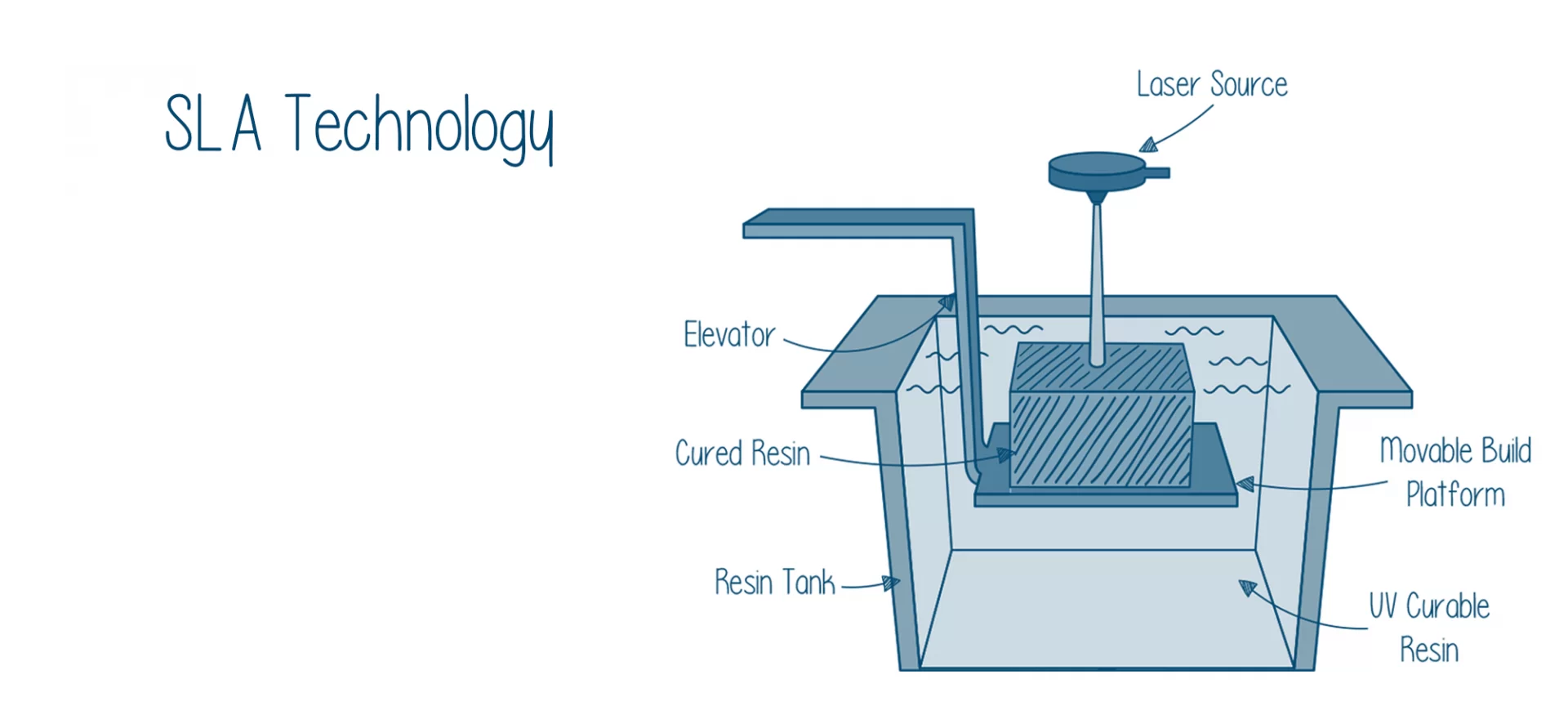

SLA is an abbreviation for stereolithography. It is the most ancient 3D printing technology still in use today. Unlike DLP, the SLA 3D printer hardens the polymer with a laser beam.

The UV laser is directed to two galvanometers on SLA 3D printers, which correct the X and Y coordinates that are traced out to a cross-section of the model. The UV laser beam sweeps across the print in a continuous motion, hardening the photopolymer as it does so.

The 3D printing method divides the three-dimensional design into numerous sets of coordinates for each layer, which are delivered to two galvanometers.

What is DLP?

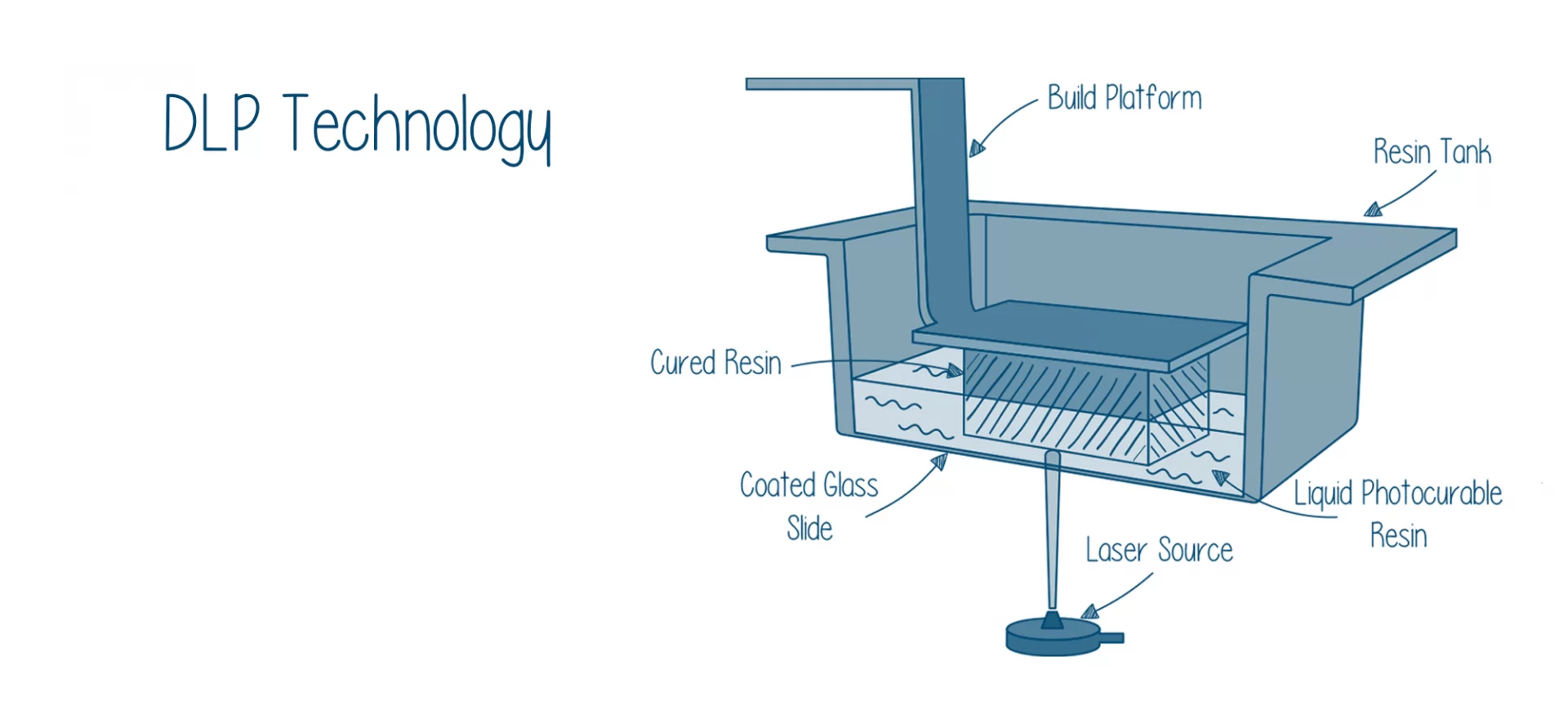

DLP is the abbreviation for Digital Light Processing. The DLP technique has several similarities to the photopolymer-based Stereolithography 3D printing process. A traditional light source, such as an arc lamp, is combined with a liquid crystal display panel in the DLP 3D printing method.

In DLP printing, the vat of liquid polymer is safely exposed to UV light. The procedure begins with the 3D picture being sent to the printer. Slices of the 3D image are projected on the resin layers via an in-built projector that rests beneath the resin container.

The first layer of polymer in the photopolymer that is exposed to UV light hardens, and the process repeats for the second and subsequent layers. The procedure is repeated until the 3D model is completed.

DLP vs SLA: Characteristics

Printing Speed

When looking at DLP vs SLA, the DLP technology is clearly ahead in terms of print speed. The printing process is substantially faster with DLP because it cures an entire layer of resin in one go.

Unlike the SLA technique, where the resin is polymerized point by point, the DLP procedure simply affects the printing speed of the component by its height.

Print Volume

Due to the high cost of materials compared to alternative methods, such as FDM, stereolithography is not often employed to make big components. Furthermore, the construction volume is constrained by the size of the liquid resin tank.

The Formlabs 3L SLA printer has a build capacity of 335 x 200 x 300 mm, whereas the 3D Systems ProX 950 has a build volume of 1500 x 750 x 550 mm.

The Envisiontec Xtreme 8K DLP printers’ build volume is 450 x 371 x 399 mm, while the Carima model DM400A’s build volume is 400 x 330 x 500 mm.

Post Treatment

Post-treatment of items is required in all resin 3D printing procedures. This is owing to the fact that supporting structures are required for printing very thin models and must be removed after curing.

This phase might take a long time and is one of the main drawbacks of resin 3D printing. In both the SLA and DLP processes, the changes in post-processing are primarily due to the material used.

In addition to cleaning the liquid resin parts using isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether (TPM), the drying, removal of support structures, possible post-curing, and, if necessary, sanding and painting the parts should all be considered.

DLP vs SLA: Major Differences

While the benefits and limits of both SLA and DLP are similar, there are a few major differences to be aware of if you’re considering purchasing your own resin-based printer.

DLP Printing is Faster

The printing speeds are the most noticeable distinction between SLA and DLP. SLA printing works by tracing the pattern of an entire layer with a single UV laser beam before moving on to the next.

This isn’t a slow procedure because it just takes a few seconds (or less than a second in some circumstances), but it’s still a long time compared to DLP printing.

A complete layer is cured at a time in DLP printing. This means that regardless of the cross-sectional area of each layer, DLP printing speeds remain constant. If you need to print numerous little objects at the same time, a DLP printer will finish them significantly faster than an SLA printer.

SLA offers Better Finishing

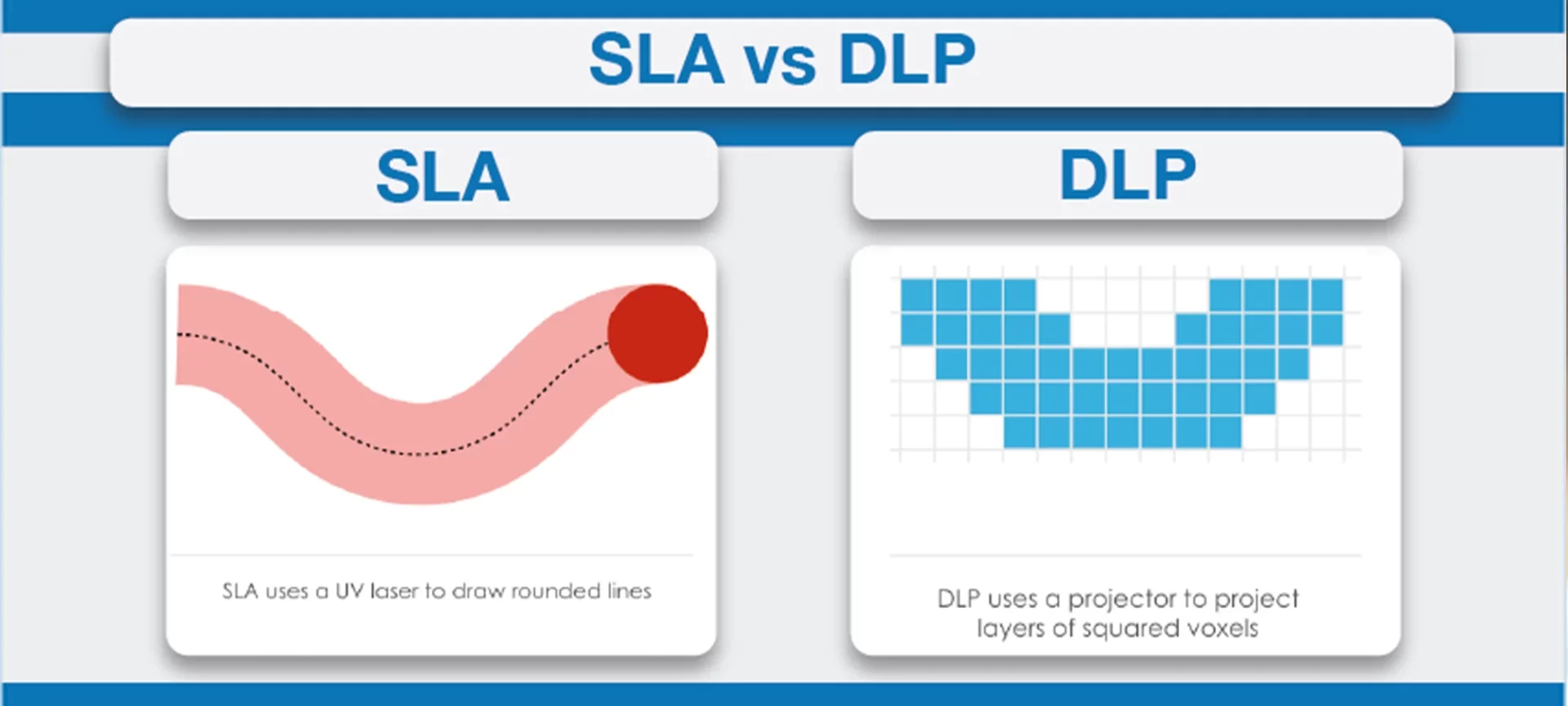

DLP printing’s superior speed comes at a cost, as you might imagine. Because the UV laser’s tip is in the shape of a circle, it makes perfectly smooth curves during SLA printing.

The LED lights used in DLP printing, on the other hand, cast light in the form of square pixels. Even though these square pixels are relatively small, voxels, or artifacts, can appear, especially on curved surfaces.

SLA prints feature less pronounced printing artifacts that will need to be completed and polished away due to the difference in resolution between SLA and DLP prints. A DLP print still looks nicer than an FDM print, but you’ll have to put in some extra effort to make it great.

SLA Printers are expensive and Hard to Maintain

The DMD array of mirrors is no longer used in modern DLP printers, instead opting for a panel of LED lights. DLP printers have become less expensive and easier to maintain as a result of this advancement.

The movable deflector of an SLA printer, on the other hand, usually necessitates professional intervention for maintenance and calibration.

The way the deflector converts the slicer design into X and Y movements is a crucial aspect of the SLA printing process, and it necessitates both hardware and software maintenance. Cleaning and inspecting the optical element that deflects the laser to the resin vat on a regular basis is also required.

DLP vs SLA: Resin 3D Resin Printers Comparison

Resolution

Resolution appears in 3D printer spec sheets more than any other parameter, yet it’s also a typical source of misunderstanding. Because the basic units of the SLA and DLP processes are different shapes, it’s difficult to compare the two machines just on the basis of numerical specifications.

The two planar 2D dimensions (X and Y) plus the third vertical Z dimension that makes 3D printing possible are the three dimensions to consider in 3D printing.

The layer thicknesses that a 3D printer can create define Z resolution. Resin 3D printers, such as SLA and DLP, have some of the best Z resolutions (thinnest layers) of any 3D printing technology, and users may often pick between 25 and 300-micron layer heights, allowing designers to strike a compromise between detail and speed.

Accuracy and Precision

Because 3D printing is an additive process, each layer adds the possibility of inaccuracy, and the method by which layers are generated has an impact on the level of precision, which is defined as the repeatability of each layer’s accuracy.

Many factors influence accuracy and precision, including the 3D printing method, materials, software settings, post-processing, and more.

SLA and DLP resin 3D printers, in general, are among the most precise and accurate 3D printing technologies. Variances in accuracy and precision are frequently explained by differences between machines made by different manufacturers rather than differences in technologies.

Surface Finish

Both SLA and DLP resin 3D printers are noted for producing components with the nicest surface finish of any 3D printing method. In most cases, the variations we describe are only noticeable on small pieces or highly detailed models.

3D prints commonly have visible, horizontal layer lines because items are formed of layers in 3D printing. However, because DLP uses rectangular voxels to render images, there is a vertical voxel line effect.

Speed and Throughput

When it comes to 3D printing speed, it’s crucial to think about both raw print speed and throughput.

In general, the raw print speed of SLA and DLP resin 3D printers is comparable. Because the projector exposes each layer at the same time, DLP 3D printing has a consistent print speed that is only affected by the building height, whereas SLA 3D printers use a laser to sketch out each portion.

As a rule of thumb, SLA 3D printers are equivalent or faster when printing small or medium-size single pieces, whereas DLP 3D printers are faster when creating huge, completely dense prints, or constructions with several parts that take up a considerable portion the platform.

Workflow and Materials

The process and available materials vary more from machine to machine than from technology to technology, much as they do with accuracy and precision.

With easily swappable build platforms and resin tanks, most SLA and DLP 3D printers are “plug and play.” Some of the more modern models have a cartridge system that automatically refills the tank with liquid resin, requiring less supervision and allowing for overnight printing.

PreForm for Formlabs 3D printers comes with proprietary software to prepare 3D models for printing, whereas other manufacturers offer off-the-shelf options.

PreForm, for example, offers a one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, and functions to conserve material and time, among other features. Fortunately, the software is simple to download and test before investing in a 3D printer.

DLP vs SLA: Applications

SLA and DLP technologies are typically employed in similar industries when it comes to application situations. Resin 3D printing is commonly used in the jewelry and dental industries.

For example, the company Formlabs sells a variety of resins aimed at medical practitioners. They’re used by a lot of companies to make surgical guides and other medical devices.

However, due to the large range of materials available, resin 3D printing is used in a variety of other industries. Several resins are useful for prototyping, injection molds, and even engineering.

DLP vs SLA: Price

DLP printers are generally less expensive than SLA printers. It’s crucial to distinguish between desktop and industrial 3D printers, as it is with all types of 3D printers.

SLA 3D printers are priced between $ 3,000 and $ 4,000 on average. If you’re shopping for industrial machinery, though, the costs will skyrocket.

3D Systems, for example, sells industrial SLA solutions for as much as $ 500,000. Also, keep in mind that devices with a laser that works from top to bottom are usually more expensive.

Many additive manufacturing enthusiasts choose DLP 3D printers because they are much more accessible. Anycubic sells numerous DLP devices for around $200, including the Photon Zero 3D printer.

Professional machines, such as those produced by EnvisionTEC for the dental and jewelry industries, start at roughly $15,000. However, as is customary, prices vary depending on the manufacturer.

The Conclusion

Although desktop FDM printers have become popular, other 3D printing technologies still have a long way to go in terms of adoption.

Resin-based printing technologies like SLA and DLP may be the greatest bets for breaking into the casual hobby 3D printing industry. They are simple to use and generate 3D prints that are far superior to even the best FDM printers.

The size of the machinery is no longer an issue because there are currently a few desktop SLA and DLP printers on the market. The most significant barrier that the technology must overcome is cost – with greater upfront and ongoing expenditures, few individuals are prepared to invest in a resin-based printer.

We feel it’s only a matter of time, and it’ll be fascinating to see what the greater creative community can come up with once SLA and DLP printers become more widely available. Although there are a few differences between DLP vs SLA, they both are exemplary technologies and sooner will be widely adopted.