Filter

Showing 31–60 of 60 results

PROS:

- Accurate functional parts with intricate detailing.

- Complete coloring of parts is possible with voxel control.

- The speed of this 3D printing system is tremendous.

- You need no support material.

- It reduces waste.

CONS:

- Although the company claims it as a suitable 3D printer for offices as well as domestic use, you can hardly manage the complexities the printing systems bring to your place.

PROS:

- Ceramo Two has a build volume that is rarely seen in 3D printers specializing in ceramic 3D printing.

- The print speed of this 3D printer is in talks since its announcement. It is said to be one of the finest 3D print speed ever in the field of ceramic 3D printing.

CONS:

- Lack of proper information regarding the printer is probably something that's going to hinder the 3D printer for a long time.

- As far as features are concerned, people may find this printer expensive.

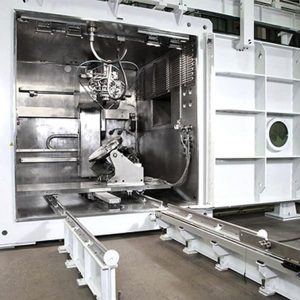

PROS:

- It lets you continuously print carbon fiber.

- Printing with a varied range of materials is possible.

- Huge build volume.

- Advanced hardware and software to give you a seamless user experience.

CONS:

- Post-processing of the parts and functional prototypes printed with the printer is difficult because of the closed print chamber.

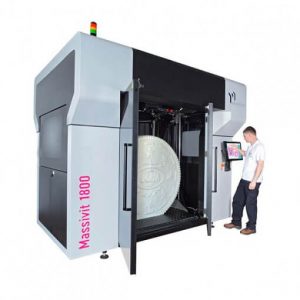

PROS:

- Users can print two different objects parallelly

- The print speed is fast

- Massivit is accurate and can create complex designs without the hassle

- One can print support free models, even for non-vertical walls and ceilings

CONS:

- It is very expensive

- Prints in only its proprietary material

- Very huge in size

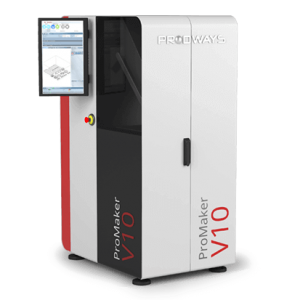

PROS:

- Compact and sturdy design

- Precise printing

- Deposits two different materials for top-notch results

- Precise PPCB printing

CONS:

- Costly and not affordable for small business owners

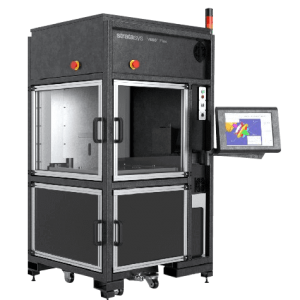

PROS:

- It creates very precise parts

- Can work with viscous liquids for printing composite models

- Company offers prompt support and technical training

- Advanced features

- Granite build platform

- Inbuilt real time slicer

CONS:

- Bulky

- Expensive

PROS:

- Wide choice of materials for 3D printing.

- High-quality printing of parts or functional prototypes.

- Great surface finish.

CONS:

- Post-processing of parts and functional prototypes is difficult.

PROS:

- Integrated process software control.

- Controlled powder management.

- High precision dynamic optical control.

- Intelligent gas flow system.

CONS:

- Operating RenAM 500Q demands a lot of expertise related to Direct metal Laser sintering 3D printing technology.

PROS:

- The highest build volume offered at the lowest possible time.

- Best quality prints

CONS:

- The cost can be a major factor in not purchasing this printer.

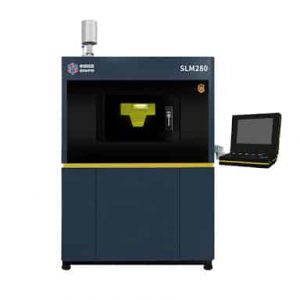

PROS:

- Inclusion of twin 400W or 700W fibre lasers

- Usage of quad overlapping laser processing

- Closed-loop handling of powder material

- Access for Integrating lasers independently as well as in parallel

- Reduced production cost for high volume metal parts. At the same time-saving material

- Improved gas flow and recirculation

- Enhanced Print Speed

- Open software architecture and customizable system parameters

CONS:

- Leftover powder overbuild platform after 3D printing

- Limited for medium-sized parts printing

- Post-processing required for support removal

- Not feasible for individual or company usage

PROS:

- The built volume of parts and functional prototypes is huge.

- The printer can print with multiple materials.

- It comes with a permanent filter.

- Multiple parts of this printer can be monitored at various times to see whether there is something wrong going on in the printer during the printing process.

- The printer is very much preferable for the mass production of parts and functional prototypes.

CONS:

- Users who are used to finding an even bigger build volume than this printer printed in a printer that costs lesser than the printer are bound to find this printer expensive.

PROS:

- Industrial-grade 3D printer, yet affordable.

- Reliable company.

- Detailing about the printer is mentioned on its website.

CONS:

- Not affordable for home users or makers. Specially designed for businesses.

PROS:

- Mass production.

- Good print speed.

CONS:

- Need support structures.

- The quality of parts is average.

PROS:

- Huge build volume.

- High-quality parts and functional prototypes.

- Printing with multi-material.

- Colored printing is a completely new concept that this printer brings into the field of 3D printing.

- High accuracy for printed models

- Users can print highly detailed geometrical models with ease

CONS:

- Highly expensive

PROS:

- Excellent print speed.

- Capable of batch production of quality aligner parts.

CONS:

- Specifically used for the dental industry.

PROS:

- High-quality tissues can be a printer.

- Color quality like no other can be produced in parts using this printer.

CONS:

- If there were more photographs on the website of the parts and functional prototypes printed by the printer, that two, it would have easier to guess the print quality.

PROS:

- Objet Eden 260VS is a cost-effective solution to the needs of 3D printing.

- Using this printer you can create parts and functional prototypes quickly.

- Designers can do functional testing before the final product.

CONS:

- The cost of the printer, seeing the build volume is more than SLA or FDM printers.

PROS:

- Print Area.

- Print Speed.

- Allowing to print without support structures.

CONS:

- Affordability. Not suitable for a lot of small businesses as well apart from the home users.

PROS:

- llows printing with more than 1000 material options.

- Printing parts with colours is possible.

- No post processing needed for 3D printed parts.

- Compatible with a user-friendly GrabCAD print software.

- Quality of parts is unmatched.

- Parts exhibit high quality and smoother surface finish.

CONS:

- PolyJet 3D printing is a complex process, even for professionals. Hence, Objet 500 Connex3 demands skills and attention for its operation. You may also need the training courses offered by the company. In short, the technology has a steep learning curve.

- The printing system demands huge one-time investment.

PROS:

- In giving out the complete details about the printer, the company excels.

- The limitation material is lifted and you as a user, can print with more materials using this printer than others.

CONS:

- Heavy. But what else can you expect from an industrial 3D printer with high print volume?

- Expensive

PROS:

- Able to print with many materials.

- Can print parts and functional prototypes of layer resolution starting from 50 microns to 1200 microns.

- Offers a huge build volume.

CONS:

- The printer does not have the Cartesian mechanism of 3D printing. Manufacturing parts and functional prototypes with Delta mechanism has its own inherent flaws and is not able to give out the amount of print quality that’s possible in Cartesian one.

PROS:

- Huge Build volume and high accuracy at an affordable price.

- Closed chamber, high rise in temperature quickly.

- Fast print times.

CONS:

- To know the exact price, you need to request its quote.

- Software information is not specifically mentioned. You need to search for this information.

- Apart from the claims, and layer resolution, you do not get to see a single photograph of part or functional prototype printed by this 3D printer to judge its quality.

PROS:

- Close loop controls for different parts of the printer.

- Automated controlling of surface level as well as other parameters.

- High quality of parts and functional prototypes.

CONS:

- The cost of the printer would be an issue while buying the printer.

PROS:

- Eccentric design innovation.

- A full-stack solution involving powder handling and inert powder unpacking.

- One-click calibration.

- In-situ metrology sensors for minute control.

- Higher throughput with dual laser sources.

- Lesser risk of part collisions.

- Available in two different configurations.

CONS:

- Sapphire is a very complicated system and it takes time to understand it and gain complete control.

- Printing with Sapphire is a costly affair. It demands huge one time investment and regular high cost maintenance.

PROS:

- Highest build volume for sand 3D printing.

- Excellent layer resolution.

- Seamless integration.

- Maximizing productivity.

CONS:

- Cost is a huge concern for anyone who is not a well-established player in the 3D printing market for years.

- Also, can this printer system be equally efficiently used for making small parts, as it can be batch productions and big parts, is a concern.

PROS:

- Huge build volume.

- Ability to print with multiple materials.

- Touch screen interface.

- Build-in camera.

CONS:

- The closed system of 3D printing.

- Post-processing of parts and functional prototypes is an issue.

PROS:

- Unmatched print quality

- Provides huge build tray and for manufacturing large parts with ease

- High operational efficiency.

- Huge touch screen interface.

- 5 times faster print speed than metal 3D Printers

- Saves wastage and very well designed

- Users can optimize the cost of the parts utilizing the best possible design choices.

CONS:

- Demands lots of investment of money, time, space and efforts.

- Not suitable for home users.

PROS:

- Unsurpassed part quality with 99.9 percent density, isotropic uniformity, and extremely low shrinkage can be printed using Carmel 1400 M.

- The printer offers an unprecedented level of design freedom to its users by letting them control every minute aspect of the 3D printing process which wasn’t possible before. It permits the making of complex geometries, fine details, nearest net shapes as well as smooth surfaces.

- Carmel 1400 M delivers unrivaled operational efficiency by providing automated support planning, easy support removal, and simple and safe operation.

- It guarantees to provide no material waste.

- Compatible with user-friendly software.

- Features a large touch screen user interface for letting users simply control and monitor various functions.

CONS:

- Various aspects of the printer are very complex and thereby demand in-depth knowledge about the printing technology for understanding.

PROS:

- High quality print

- Plug and play design

- Automatic calibration

- Dual extruder

- Compatible with soluble support material

- Print with different usual and flexible materials including PEEK

- Allows the use of third party materials

CONS:

- Expensive and solely for industrial use

PROS:

- Direct metal parts and functional prototypes can be produced.

- Parts have high mechanical properties and high relative density in which post-processing is necessary.

- A wide range of materials to choose from.

- Parts that otherwise take days to complete can be made in hours using this printer.

CONS:

- Post-processing of parts or functional prototypes is a very hectic process and that might increase the overall printing time while you are having a batch production.