FDM (Fused Deposition Modeling) is one of the most popular 3D printing processes among available AM technologies. Existing since 1989, there have been many upgrades made to the machine based on this technology. However, it was only after 20 years that 3D printing started gaining popularity.

Thanks to the cheaper substitute, the FFF (Fused Filament Fabrication) technology, desktop 3D printers’ sale sky-rocketed. The question is: Are these processes the same? To clear the confusion, let us check out the detailed comparison between FFF vs FDM technologies.

A Brief About FDM and FFF 3D Printing Technologies

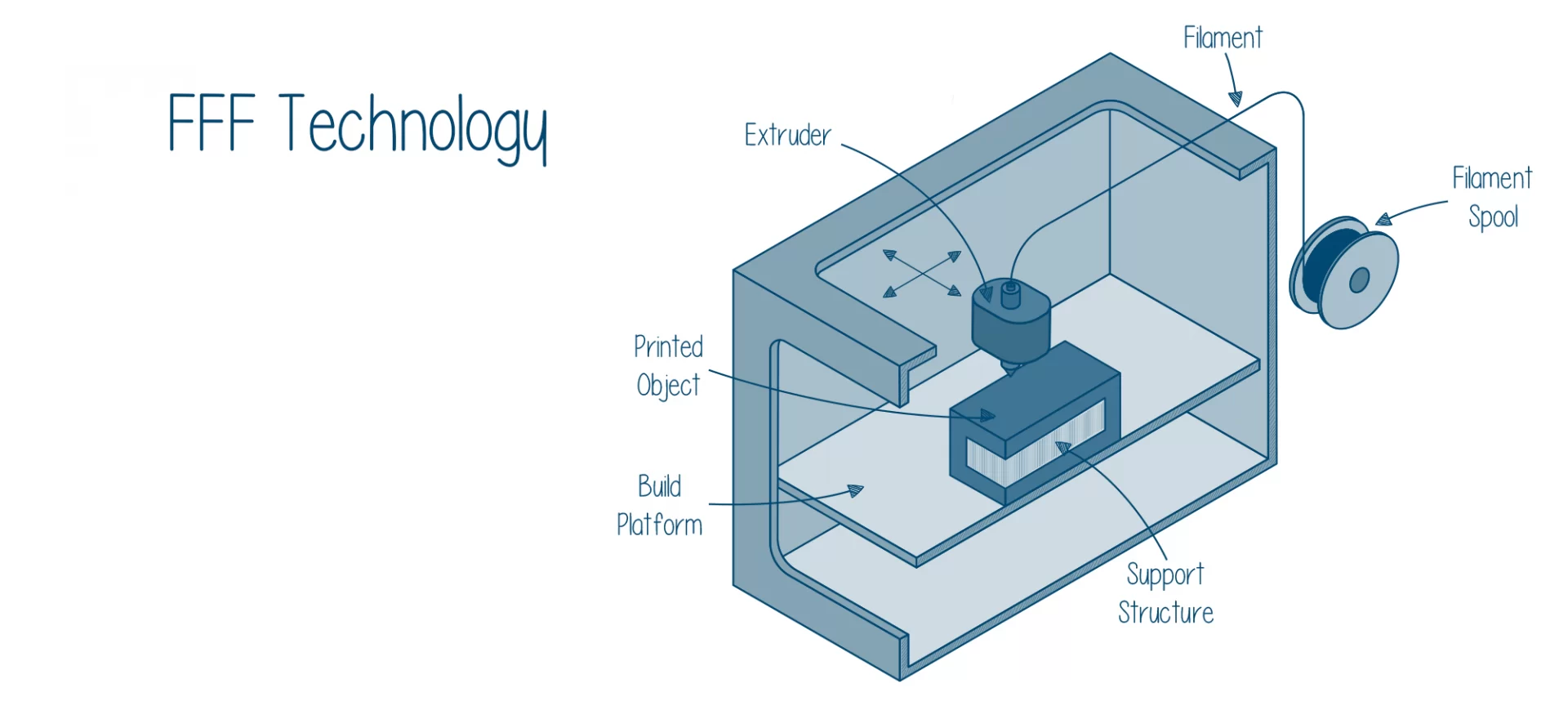

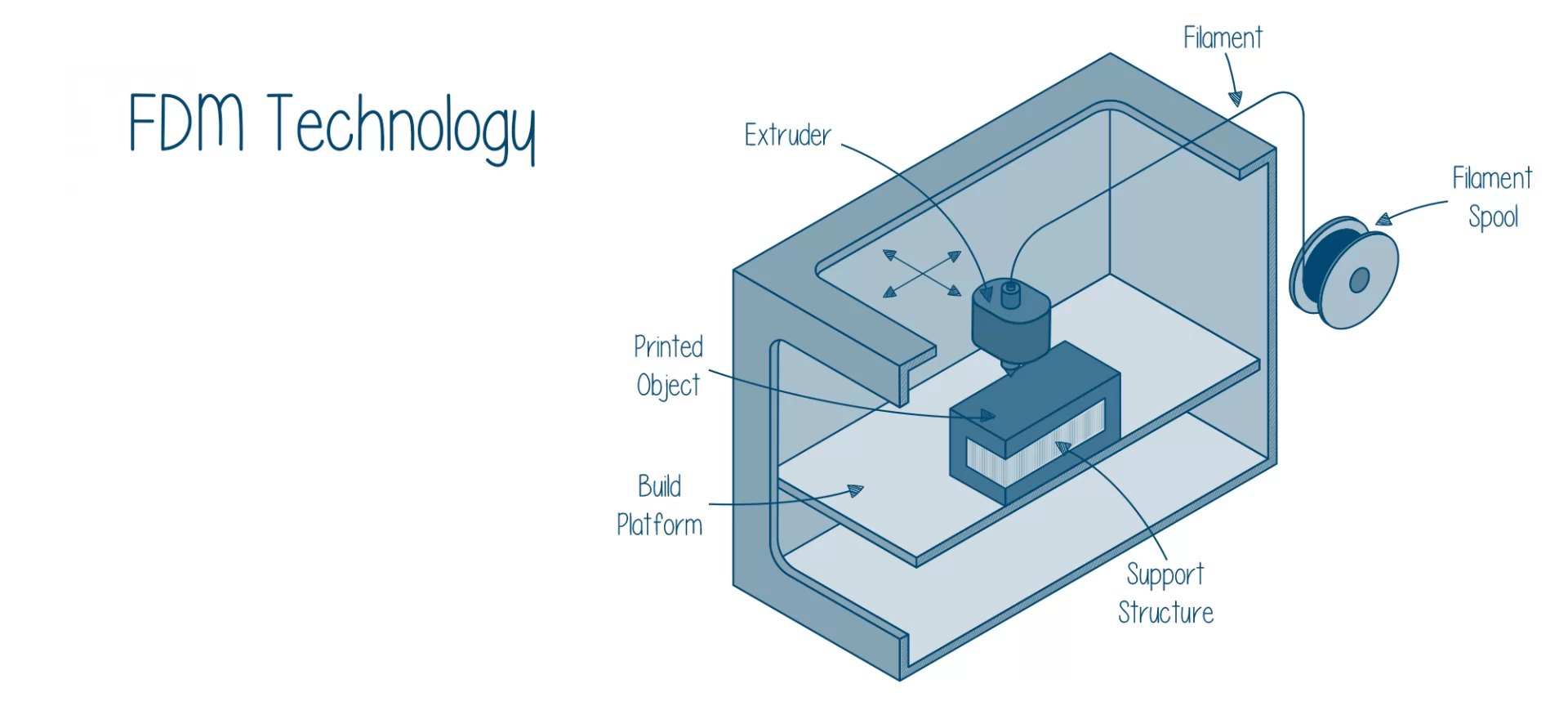

FFF (Fused Filament Fabrication) is a process that builds objects by depositing melted filaments, one layer over the other. Using the slicing software, the entire process of deposition takes place in a specific manner.

Using the special filament made of polymer, the technology ensures fast manufacturing of objects in a controlled environment.

As mentioned before, the basic workflow of FDM (Fused Deposition Modeling) is equivalent to FFF. However, the latter was a proposed RepRap project, originated in 2005.

Hence, you must not expect a lot of differences between FFF vs FDM technologies. Rather, the major difference lies in their historical background, and for the reasons, they were brought to use.

FDM, developed by Stratasys in 1989 became the company’s proprietary 3D printing technology. When it comes to its processing, the FDM 3D printer hosts an extruder, a print chamber, a nozzle, along with a filament feeding system.

When in operation, the material is guided through the feeding system to the extruder. This is where the plastic material melts and is deposited over the build plate inside a print chamber. The process repeats, layer by layer to create the desired 3D model.

This entire operation of FDM printing happens inside an isolated chamber. To avoid warping and other similar issues, the printer maintains a consistent temperature of around 90°C inside the print chamber. What’s interesting is that the parts retain the mechanical properties of the material after printing completes as well.

It is also possible to regulate the temperature inside the print chamber, depending on the type of filament used.

How Does FFF 3D Printing Come to Existence?

Right before Stratasys’ patent regarding the FDM technology was about to expire, the RepRap members wanted to find a different name for a pretty similar process as FDM to avoid any clash with proprietary terms.

Hence, to be able to bring their innovation for use by others, while at the same time dodging the infringement policies regarding FDM copyright, the RepRap community decided to coin their invention as FFF or Fused Filament Fabrication.

The motive of the community was to come up with a similar solution that enabled faster production of complex designs without involving expensive and industrial-grade tools.

For instance, when working with FDM machines, users must heat the complete print chamber when printing. On the contrary, FFF 3D printers didn’t have any print chamber in the first place.

This was done to make the entire process as cost-efficient as possible. However, there are certain drawbacks of the same.

In FFF devices, the filament may come across temperature fluctuations when exposed to cold surroundings at the time of extrusion, before depositing on the heated bed. As a matter of fact, there are many affordable printers that do not even host a heated bed.

This employment of temperature fluctuations results in unwanted residual stresses. However, that is not the case with FDM printers.

Hence, the parts produced by FDM machines are more desirable, parts being able to maintain the same mechanical properties as their materials. That is why FDM technology is preferred when it’s about high-grade details involving functional prototypes.

In other words, FDM was initially coined for those printers used within industrial setups. On the other hand, FFF devices are usually preferred by home users and hobbyists.

Which One is Better – FFF vs FDM?

You must have got an idea about the answer to the question by now. However, let’s find the details of how FDM is better than FFF 3D printing technology.

FDM on Temperature

As mentioned, FDM printers contain a print chamber that maintains a consistent temperature of about 90 degrees Celsius. Hence, printing with ABS and other FDM materials becomes easy.

This chamber, being isolated from the outside surroundings, allows for a consistent flow of filament from the hot extruder onto a hot build platform.

When passing through the hot temperature throughout the deposition process, the resultant parts carry the mechanical properties of the base material. Therefore, considerably strengthening the adhesion between layers and preventing printing issues such as warping or curling.

Unlike FDM, FFF printers do not host any heated chamber. This is because of the patent that Stratasys owns related to thermal separation. As a result, the filament in an FFF 3D printer transfers from a hot extruder and passes through a cold surrounding before finally reaching the unevenly heated hot build platform.

And, as you can expect, the transition from hot to cold to hot medium gives way to residual stresses. Hence, finally impacting the overall quality of the printed parts.

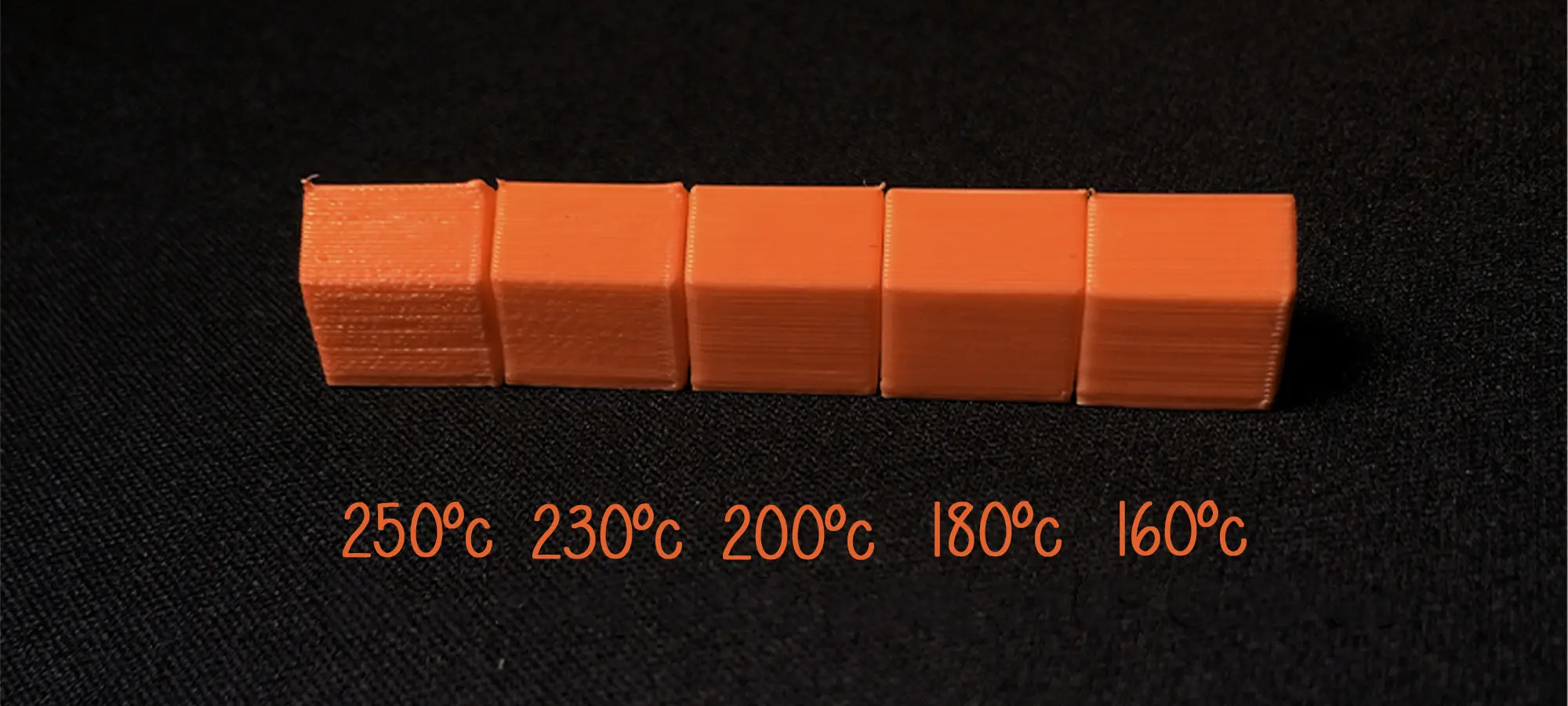

Mostly because of the immediate cooling of polymer that happens at the time of extrusion, the temperature difference adversely affects not only the mechanical properties of the final part but its tolerances too.

It is also noteworthy to understand that the FDM printers’ motors are placed outside the enclosed space. FFF printers have to include a heated bed for increasing the ambient temperature throughout the filament flow and for higher layer adhesion.

FDM can Work with More Advanced Plastics

FDM, with its unique features, can tame some of the most notorious materials commercially available. The list includes but is not limited to Nylon, Polycarbonate, ULTEM & PEEK, and more. And, this is all because of the enclosed chamber that these printers based on FDM carry.

Not just that, the FDM filaments are manufactured within strict quality control processes. Following some of the stern ISO guidelines for quality & traceability maintenance, the manufacturers of FDM filaments are able to produce better materials.

For instance, a small stretch in the filament while deposition could turn a circle into an oval. Therefore, the consistency of materials matters a lot in 3D printing high-end parts and functional prototypes. Even the tiniest change in diameter or length could result in failed prints.

FFF printers trade off with the quality of the material to keep the printing cost as minimum as possible. Hence, resulting in less accurate parts when compared to the ones created using FDM 3D printers.

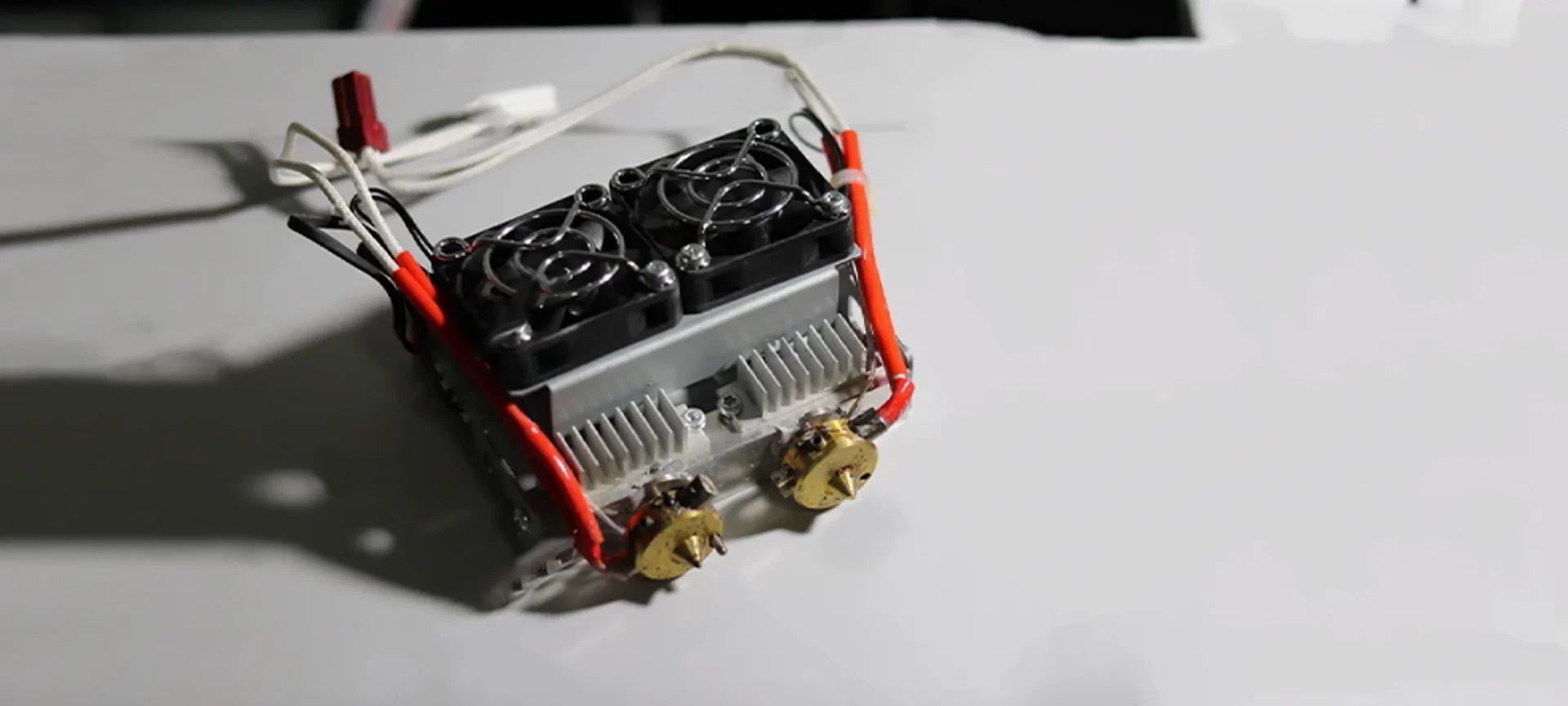

Use of Dual Extrusion in all FDM Printers

When it comes to printing with FDM machines, you will rarely find it difficult to create complex geometry. Thanks to the dual extrusion technology that every FDM industrial printer hosts.

In order to create smoother finishes, FDM 3D printers do not forget to make use of soluble support material. These materials are easily dissolvable when placed inside a heated ultrasonic tank.

In the process, the parts do not undergo any damage when waiting for the PVC material to dissolve in water, as it’s the case with the FFF dual extrusion system.

The FDM support materials are specifically created for working with a particular thermoplastic. Hence, offering the best results, no matter what temperature one maintains within the print chamber.

Talking about the FFF machines, it’s very recent that these printers have started coming up with dual extruders. And, these work with PVA, a water-soluble material that easily dissolves in liquid.

Specially designed to tune up with PLA filament, PVA does work fairly with the material. However, when moving to further advanced filaments such as ABS and TPU, various issues including warping, delamination, etc, becomes highly apparent.

No wonder why FFF 3D printers are more associated with home users and not the industrial setup.

Best FDM 3D Printers

Being industrial-grade 3D printers, you might find these FDM printers expensive, but they sure do the job with utmost precision. And, definitely are worth every attention.

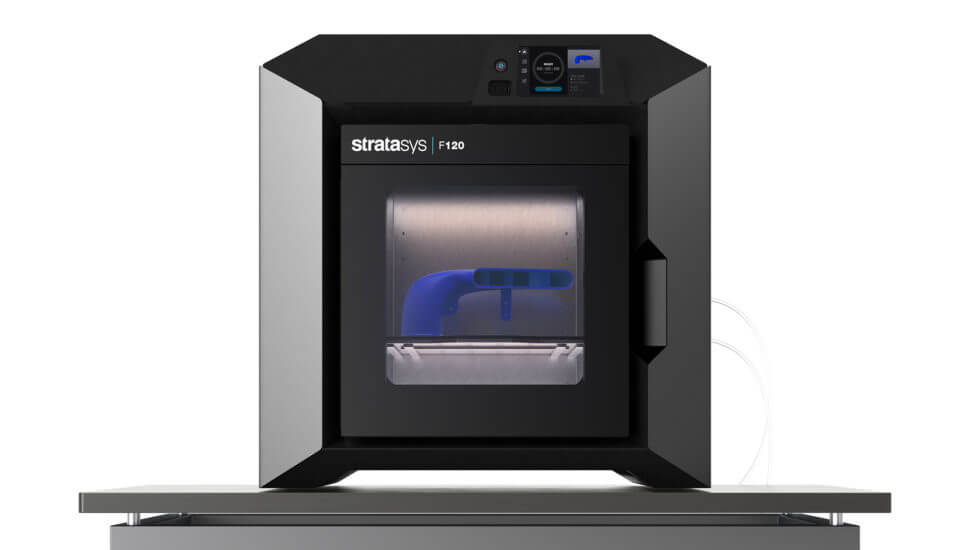

Stratasys F120

A 3D printer designed to excel in every aspect, F120 is a very reliable machine, suitable for different high-end applications. It’s a tabletop version and more likely a desktop 3D printer, occupying compact space and snuggly sitting on the desk for accepting all your printing jobs.

The printer’s 97 percent accuracy is far ahead when compared with the 57% accuracy of its closed competitors. With 0 hours of downtime, users can successfully create parts, over and over again.

With a user-friendly interface and precise results, the printer happens to be very popular among different niches. Almost 2 or 3 times faster than the usual desktop 3D printers, F120 can work for hours without any interruption to create parts with ABS, ASA along soluble support materials.

It’s a plug-and-play machine with an easy setup. What else one would need, if not F120 for attaining the best results at an affordable price for an industrial 3D printer?

|

Stratasys F900

If you need consistent results and want to print large models, you can depend on F900 without any confusion. The printer is designed to provide real manufacturing solutions to industries seeking quality and speed, coupled with ease of production.

With larger build space along with proven accuracy, the machine easily meets a variety of production demands.

Alongside, its compatibility with diverse materials, help users with a wide range of applications. You can choose from high-performance polymers to engineering-grade thermoplastics to suit your needs and manufacturing demands.

|

Best FFF 3D Printers

For consumers and hobbyists, being able to work with a 3D printer means a lot. And, the RepRap community has made that possible, though trading off with quality a little bit. However, making 3D printers accessible to end-users is itself an achievement.

So, why not explore some of the high-quality FFF 3D printers you can choose to work with?

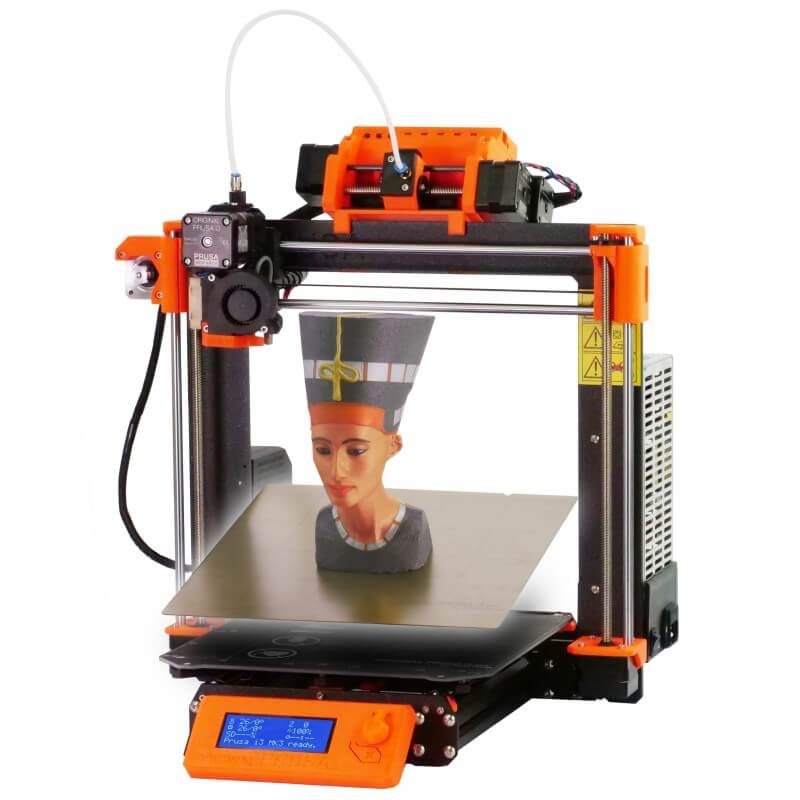

Prusa i3 MK3S

Hosting a build volume of 250 x 210 x 200 mm, the printer can help achieve a minimum layer resolution of 50-micron. Not just that, the printer is very accurate and reliable. Apart from that, you can certainly enjoy printing models on these simply designed machines, created for offering ease of operation.

The machine is available as a DIY Kit as well as in assembled design. You can choose what your pocket allows. At the end of the day, it’s still the same printer. One of the fastest desktop FFF 3D printers, Prusa i3 MK3S is a real gem offering a travel speed of up to 200 mm/sec.

|

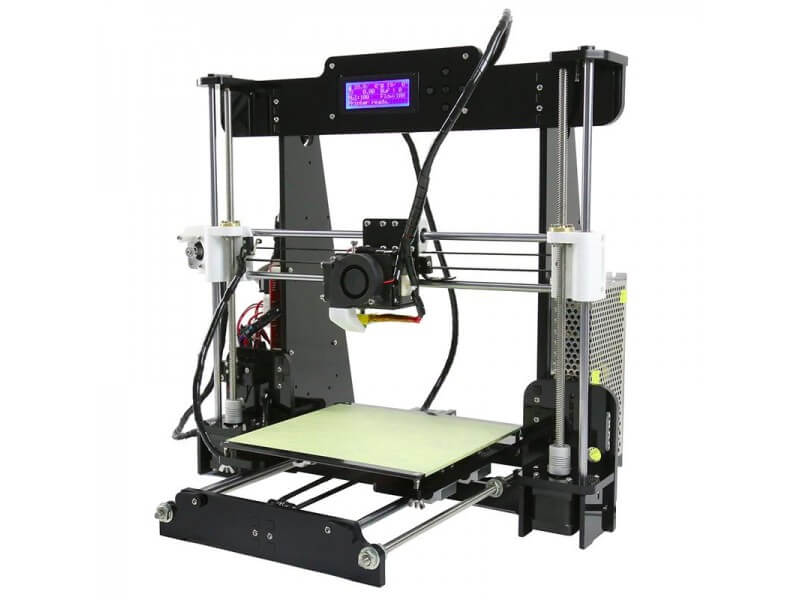

Anet A8

Yes, the printer is available for less than $200. However, do not judge its quality depending on its price. Its amazing performance, with a minimum layer height of 0.1mm is more like a dream come true for this price tag.

You may have to ignore the firm aluminum frame or the fascinating dual extruder. However, the Anet A8 does offer fair results at such an affordable rate. It comes with a build volume of 220 x 220 x 240 mm and is accurate in printing. You can design complex parts, expecting a few visible layers.

Overall, it’s a really budget-friendly printer, offering decent results.

|

The Conclusion

There have always been a lot of myths around FFF vs FDM differences. Overall, they do work in a similar fashion with a little here and there.

If you are operating a business, you might like to check out the expensive industrial-grade FDM printers. On the contrary, the FFF printers easily suffice for makers’ needs.