Filter

Showing 61–90 of 285 results

PROS:

- Easy to assemble

- Provide amazing prints

- Can print fast without compromising the quality of the prints

- Removable magnetic build surface

- Open-source

- Affordable

CONS:

- Filament loading may seem difficult

- Manual print bed leveling

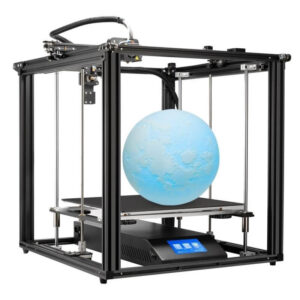

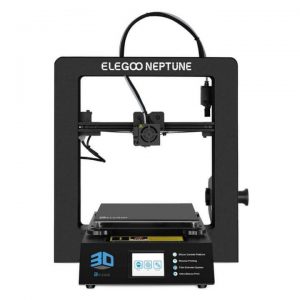

PROS:

- Generous build volume.

- Sturdy cubical frame.

- Good print quality.

- Flatbed for good adhesion.

- BLTouch probe for auto-leveling.

- The assembling process is easy as well as fast.

- Touch screen interface.

- Dual-axis and stepper motors permit stable movements for accurate prints.

CONS:

- Cheap Bowden extruder.

- PSU issues.

- Fans are noisy.

- The hot end is not able to keep up with larger nozzles when maintaining the same speed.

PROS:

- Reliable.

- Produces solid print quality.

- Affordable.

- Is super quiet in operation.

- Features a Capricorn Bowden tube.

- Comes semi-assembled.

- Hosts a sturdy, cubic build structure delivering an attractive look.

CONS:

- The printer’s bed leveling is tricky.

- Reusing the magnetic bed after cleaning is very difficult.

- Management of wire cables is not proper.

PROS:

- It offers a pretty large platform

- It has three different extruders

- By ensuring smart settings and design, the printer enhances the ease of use to the next level

- Support for a wide range of filament materials

- Wired as well as wireless connectivity available.

- High printing speed

CONS:

- The 3D printer is costly and isn’t affordable to all

- Few challenges with precision if the settings parameters are not adjusted properly

- Support for only proprietary filaments

PROS:

- The print speed of this printer is very fast compared to the print speed of other printers in the same price range.

- It offers high print temperatures because of which printing with materials that do not melt at low temperatures is possible.

- Delta Wasp 20 40 Turbo 2 is robust and reliable. It won’t vibrate or make a lot of noise during printing.

- Dual Extruders are optional when printing with this printer.

- The manufacturer of this printer has given freedom if a user wishes to print using third-Party filament support.

CONS:

- The price of this printer could seem expensive to the beginners. It is much expensive than the DIY kits

PROS:

- Excellent part quality.

- Competitive cost per part.

- Best in class repeatability.

- Wide material compatibility.

CONS:

- Although we should not mention price as a con of the production system, because this is either state of the art technology, but it seems way beyond the reach of small businesses.

PROS:

- Easy two-step processing.

- High-quality parts.

- Designed for office.

- Software controlled smooth workflow.

- Straightforward hardware.

CONS:

- Dekstop Metal Studio System 2 is meant for those who can afford a huge one-time investment. So, only for industrial manufactures interested in building high quality metal parts on demand.

PROS:

- No-hands on production concept.

- Printing happens at room temperature.

CONS:

- There is no gallery wherein pictures of parts and functional prototypes are displayed which gives you a little more idea about the accuracy that the company is stating all along.

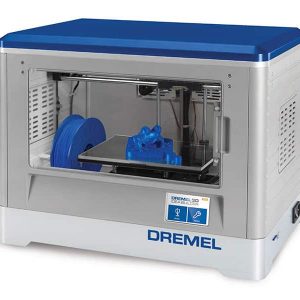

PROS:

- Easy to use

- Compact and affordable

- Fully assembled

- Decent quality prints

- The easy bed leveling process

CONS:

- Runs only with Dremel PLA filament

- Do not provide WIFI connectivity

PROS:

- Print removal is easy.

- 30 percent faster than 3D40.

- Reliable 3D printing.

CONS:

- Oozing of the filament is a bit of a problem.

PROS:

- The printer is easy to set up and use

- There is an excellent print quality that the printer produces, whether it’s a part of a functional prototype, regardless of the industry you wish to use it in, it will deliver up to the mark

- The printer sets in front of the world a perfect example of safety and reliability. Often those two are considered counterparts of each other and the printer that has the former lacks the latter. But with Dremel Digilab, the manufacturer has proven that both can be present in almost equal amounts

- 3D45 has a comprehensive ecosystem that is tailored for education

CONS:

- Whenever you are printing in this printer using a third-party filament, you’d notice that the print quality is lower than what it was

- Although it can print with some materials that are advance when you typically turn on to materials like Nylon, the printer starts to show some tantrums

- The closed system that this printer has limited creativity to an extent

PROS:

- Auto Calibration

- Moving print bed

- Accuracy and detailing in minute parts and their edges

CONS:

- Resin bottles are to be bought from the company

- The price of the printer makes it look un-affordable to the experimental beginner in the field of 3D printing

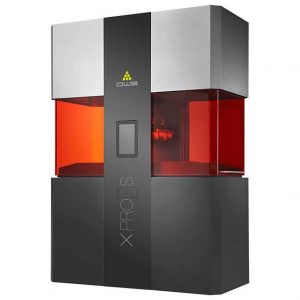

PROS:

- This printer's company is a leader in making additive manufacturing technology 4.0.

- Compatible with a wide range of DWS proprietary resins.

- Has the ability to produce transparent materials, nano-ceramic materials, and materials that are used to make investment casting models.

CONS:

- It is a single laser system.

- Post Processing Requirement.

PROS:

- The printer is accurate

- It provides amazing resolution

- Sturdy frame

- Power outage recovery

- Heated build plate

- Affordable

CONS:

- Manual calibration

- Only supports PLA

PROS:

- Extraordinary print quality.

- Minimal setup required before 3D printing.

- Simple yet effective construction.

CONS:

- USB connection is located at a little odd place.

- The fan’s operation produces a lot of noise.

- Heavy use can trip the printer’s firmware.

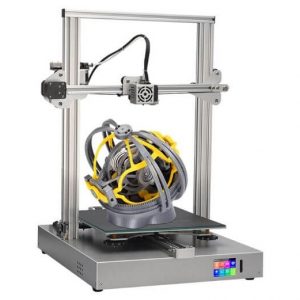

PROS:

- Fast printing and less maintenance.

- Outstanding prints and ultra-accuracy.

- Sturdy build quality.

- Multilingual interface.

- Good warranty and service.

CONS:

- Small build volume.

PROS:

- Faster part curing

- Decent build space when compared to other desktop resin printers

- Coupled with powerful slicer

- High quality parts

CONS:

- Parts possess a lesser pixel density when compared to its predecessors.

- It is not equipped with a top-down removable vat.

- The cooling fans are louder.

PROS:

- The 3D printer is simple to setup

- You can achieve high-quality print quality

- Compatible with a variety of materials

- Comes with titan extruder

- It has the glass carbide build plate

- Enough space for printing

- Includes necessary accessories to complete the setup and start 3D printing

- The SD card has the Elegoo Cura

CONS:

- Bed Leveling isn’t that easy

- Not assembled

PROS:

- Easy to operate

- Sleek design

- Plug and play

- High precision

- Comes with one year warranty

- Twice as fast as traditional methods

- Parts look and feel like traditional gypsum models

CONS:

- Very expensive

- Smaller build space

PROS:

- Intricate detailing of parts possible.

- User friendly.

- Industrial-grade 3D printing possible.

CONS:

- Small build volume.

PROS:

- Offers you printing with a lot of printing materials.

- You can print with four different build sizes and four different voxel preferences using P4K Series.

- The quality of parts manufactured using the printers is excellent.

CONS:

- The build size of parts and functional prototypes is very small.

PROS:

- It provides 10 times faster speed than other DLM machines

- It provides high-resolution printing

- Plug-and-play technology helps in easy operation

- The user-friendly interface provided with the screen touch system for ease of setting the printing parameters

- Compact and can be accommodated in small space as well

- Reduced need for the support structure

CONS:

- It is expensive

- Not accessible for those with low budget

- Post-processing requirement

PROS:

- There is a separate tab of success stories that tell about which printer was used in which industry to generate what!

- If you plan to be an EOS customer, there is a lot to gaze all over the website and learn from.

CONS:

- The website is too long. And, so if you are not used to navigating in a proper fashion, you might get lost!

PROS:

- Excellent management of various aspects of 3D printing process is possible using various parts of this 3D printing system.

- No need for any support structures.

- An extraordinary quality of parts and functional prototypes for various applications are possible using this 3D printing system.

- You can choose from a variety of different 3D printing materials.

CONS:

- The high cost of printing per part when compared with other 3D printing technologies.

- Relative to other melted parts, DMLS parts are porous and their porosity can be controlled but not eliminated in the 3D printing process during post-processing.

PROS:

- Huge build volume.

- Four different laser sources for melting and fusing, leading to consistency in the overall surface of the part or functional prototype.

- Multi-material printing.

- Good quality part and functional prototypes.

CONS:

- Requires huge one time investment.

PROS:

- Four high-power laser sources to ensure coherent melting and fusing of metal powder and excellent surface finish in parts and functional prototypes.

- Sophisticated material management and software systems for ease of use and operation after, before, and during the 3D printing process.

- Ability to print with various 3D printing materials.

CONS:

- Buying EOS M400-4 or even leasing it, requires a huge one-time investment, monetarily as well as in training and operation.

PROS:

- High-powered laser

- Laser Power Monitoring with Gas Management System

- Stand-alone automatic powder-sieving

CONS:

- The cost of the printer is something many might have a problem with.

PROS:

- Helps to achieve amazing print quality with high strength.

- Offers a huge range of materials.

- Supports third party slicing software.

CONS:

- Post-processing of every part and the functional prototype is required.

PROS:

- Capable of creating the most complex parts.

- No debinding is required.

- A furnace was built for the office.

- Two-step bound metal printing process.

- Allows users to print any part thickness.

CONS:

- The printer and sinter furnace are two different machines, managing both of them can be quite difficult even for professionals.

- The cost of the printing machine is a lot on the higher end.