Many new companies making 3D printers have stepped into the market. Thus, selecting the best 3D printer is getting tough.

The variety is HUGE! This may confuse you and leave a big question mark on your head. “Which one to get for yourself?”

Either to get the 3D printer which prints with high quality? Or the one that is easier to set up and use? Surely many such other queries will be on your mind.

Worried about these questions? Now you just don’t need to! This article will enable you to make an informed decision.

What Are Open Source 3D Printers And How Do They Work?

The term Open Source means a device or program that allows collaboration and sharing with the community for bringing further improvements in the existing version. This results in much faster, better, and innovative technology for everyone!

This means there is no IP holding you back and restricting you from experimenting. You can continue to improve and experiment with 3D printer design. This welcomes jaw-dropping revolutionary developments in this magical 3D printing world.

Open-source 3D printers can work with any software. It supports any resin that you want to use. This keeps them light on your pocket along with offering numerous advantages.

What Are The Benefits Of Open Source 3D Printers?

The benefits of open-source 3D printers are numerous for both manufacturers and users. Manufacturers win a great deal by having a strong relationship with their community.

Users can advance the products for the manufacturer using open source. This creates a process in which everyone involved contributes to the development of the 3D printer.

The 3D printing industry has a solid foundation. Depending on open source hardware and free software, its base continues to grow stronger. Some “closed” 3D printers provide a streamlined and easily understandable printing process.

Open-source 3D printing does all of that and more. With open source technology, users can improve performance and add new features. It makes the printing process easier and more reliable.

Open source printing equals user freedom. A 3D printer grows in capability alongside you. It gives you a more enjoyable experience with your 3D printing filaments.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Anet A8 | Most Advanced | 9.7 | |

| Original Prusa i3 MK2S | Extraordinarily Efficient | 8.4 | |

| LulzBot Mini | Nimble & Sturdy | 9.8 | |

| BCN3D Sigma R19 | Beginner friendly | 9.4 | |

| Ultimaker 2 Go | Most Consistent | 9.3 | |

| Creality Ender 3 | Safest option | 8.6 | |

| SeeMeCNC Rostock Max V4 | Incredibly Productive | 8.8 | |

| Monoprice Mini Delta | Most Reliable | 8.9 | |

| Flashforge Creator Pro | Office Friendly | 9.4 | |

| Creality CR 10 | Premium Pick | 8.7 |

List of The Best Open Source 3D Printers

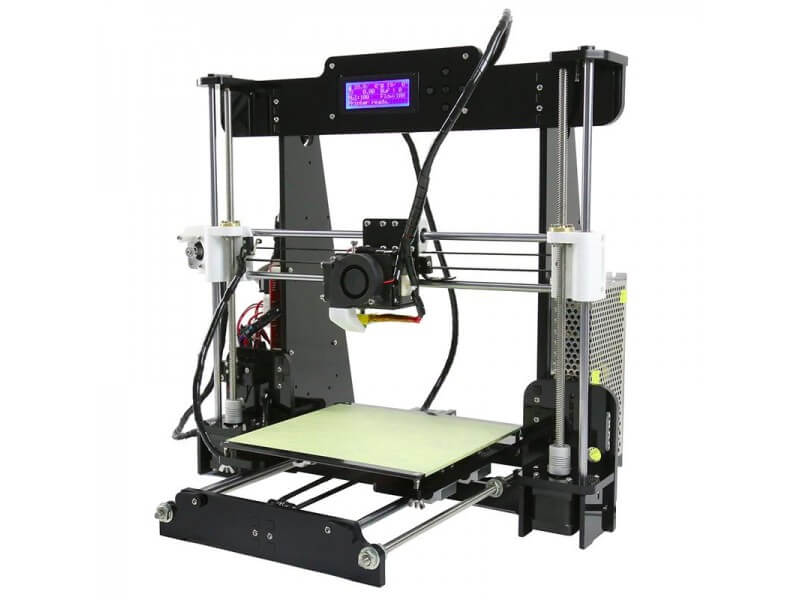

Anet A8

The Anet A8 has been on the market since 2015, and the model integrates R&D, production, and sales. It contains a magnetically movable LCD control panel that makes your operation more efficient and flexible.

The Anet A8 includes an upgraded heat bed and mainboard. This machine is delivered to your home as a kit.

The manufacturer’s information is mounted over it. The information states, for operating this printer you do not require any special knowledge or experience.

The LCD screen has five buttons for easy adjustment. It is compatible with materials, such as PLA and ABS, due to a heating plate that can reach temperatures of up to 100°C.

It supports OBJ, STL, and G-Code file format and material with a diameter of 1.75 mm. The Anet A8 has a single nozzle of 0.4 mm diameter. It prints with a speed of 100 mm/s offering a layer resolution of 0.1 to 0.3 mm.

Uses:

- The printer uses an automatic filament-feeding feature, which reduces your efforts

- The Anet A8 offers a print volume of 300 x 300 x 350 mm, ideal for large prints

- Features FDM technology

- Even if you are new to 3D printing, you can use the Anet A8 without hassle

- Affordable 3D printer kit

- Flexible to modifications

- Incorporates FDM 3D Printing technology

- Improved functionality with each tweak

- A number of 3D printable enhancements are available

- The user interface is not practical

- Need patience while operating

- Requires manual calibration

|

Original Prusa i3 MK2S

The Original Prusa i3 MK2 is a low-cost desktop Open Source 3D printer. It is an improved version of the well-known Prusa i3 3D printer.

All the parts for this 3D printer are open-source and part of the RepRap project. It has a 31% larger 3D print volume and can print up to 40% faster than other models.

This printer features automatic bed leveling. It eliminates the need for manual calibration. This open Source 3D printer is well known for its dependability, robustness, and upgradability. It is also easy to repair and maintain.

This model has E3D V6 full hot end for printing 3D models at a surprisingly faster rate. It has an impressive build volume of 250 × 210 × 200 mm.

This open-source 3D printer works with extrusion technology and has a print resolution of 50 to 200 microns.

Uses:

- Ideal for hobbyists and home users

- Uses a heated bed with cold corner compensation to avoid wrapping issues

- Heated PEI 3D print surface is ideal for a variety of 3D filaments

- Uses and supports PLA, ABS, PET, HIPS, Polycarbonates, and many other filaments, and thus it is used to work with a variety of materials and print your 3D models

- Doesn’t require any adhesives

- It uses specially adjusted firmware to reduce 3D printing noise

- Automatic bed leveling

- Noiseless printing

- Useful, professionally printed user guide

- Consistently high-quality prints

- Supports multiple filament types

- May require monitoring when surrounded by pets or children

|

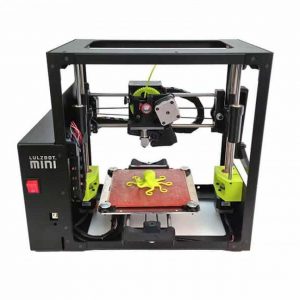

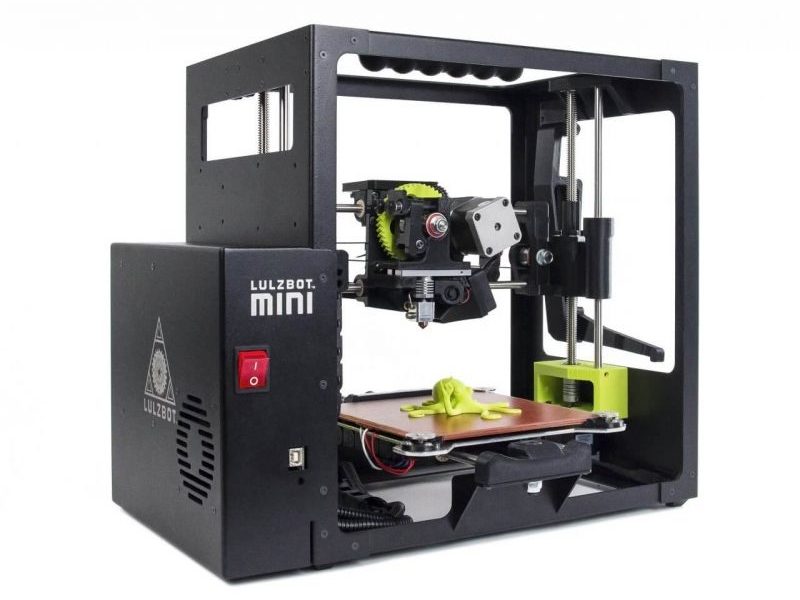

LulzBot Mini

The LulzBot Mini is a desktop 3D printer. This open-source printer is reliable and outperforms all other 3D printers in terms of usability and quality. It is agile yet sturdy and built on open-source hardware.

One thing to bear in mind is the size of the nozzle; LulzBot Mini will print larger and quicker prints if you opt for 0.5 mm over 0.4 mm nozzles.

A small nozzle is ideal for more detailed printing. It prints at an incredibly fast speed of 275 mm/sec. If you are looking for a high-quality desktop 3D printer for single extrusion, your search is over.

Uses:

- Lulzbot Mini is a joy to use daily as it is simple to operate and delivers extraordinary prints

- Produces high-precision prints, as its layer thickness ranges from 0.05 mm to 0.5 mm

- The construction surface area is 152 x 152 x 158 mm, which is large. It can easily accommodate enormous designs.

- Uses a 3 mm standard filament

- Creates products out of many filaments, including PVA, PLA, HIPS, ABS, wood filled filaments, and many other materials

- PEI print surface

- Expandable and hackable

- Produces reliable and consistent results

- Robust design

- Easy to use for beginners

- Great documentation

- Noisy

- Small build volume

- Needs PC tethering

- No onboard control

|

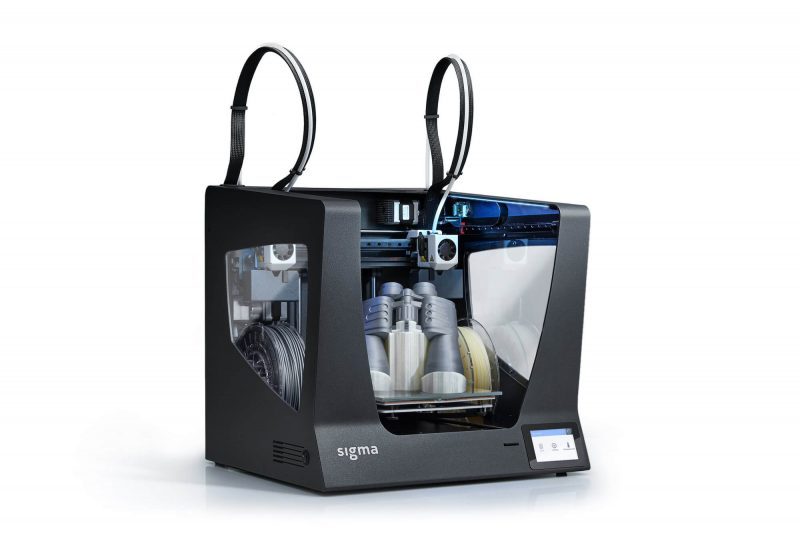

BCN3D Sigma R19

If you want to make a career out of 3D printing technology, you can start or scale up your experiments with this open-source 3D printer. BCN3D Sigma comes with the most up-to-date connectivity features.

It also offers a free workflow on the BCN3D cloud platform. Sending print files to the printer is now easier than ever with this open-source 3D printer!

This printer operates smoothly, as the manufacturers incorporated e3D Hotends, which are the most dependable extrusion hot ends.

The Sigma D25 features FFF 3D printing technology. The printer has a print volume of 420 x 300 x 200 mm and an independent dual extruder.

Uses:

- It uses an amazing filament runout sensor so that you are informed before the filament is about to end

- Sigma has a 5″ multilingual touchscreen to facilitate interaction between the user and the printer

- Print models of the desired size using its sufficient build space of 210 x 297 x 210 mm

- BCN3D features a unique and innovative system of the dual extruder. It allows printers to work independently, producing complex designs with ease

- Wireless printing

- Produces parts with large build volumes

- Delivers high-quality prints

- User-friendly interface

- Closed printing chambers make it hard for users to post-processing

|

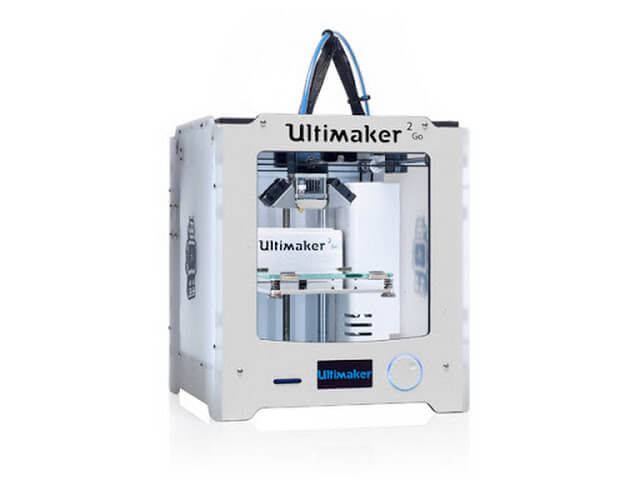

Ultimaker 2 GO

Ultimaker is known for producing larger and more stuffed machines. However, when it comes to portability, the Ultimaker 2 Go is the real ‘go to’ option for you!

This fits inside a special backpack provided by the company. This model is portable and therefore, easy to move around. Conversely, the print area is small, i.e. 120 x 120 x 115 mm.

However, in terms of performance and dependability, it is on par with its larger counterparts. You can enjoy the smoother Bowden system for flawless prints.

The price remains reasonable, and the benefits offered by this open-source 3D printer are numerous.

Uses:

- This small machine performs a wide range of tasks

- The Bowden System allows you to achieve the excellent printing quality that the Ultimaker is known for

- If you are looking for a simple to use and dependable printer that doesn’t require a lot of printing space, this model could be your best friend

- This 3D printer is compatible with ABS, PLA, and CPE 3D filaments

- The Ultimaker 2 Go has a high 3D printing resolution of 20 microns

- Uses filament with a diameter of 2.85 mm to 3 mm

- Ultimaker 2 Go employs a novel extruding system for better 3D print quality at high speed

- Affordable

- Easy to transport

- Produces high-quality prints at a faster speed

- Works with ABS, PLA, and CPE filaments

- Nozzles are difficult to unclog

Creality Ender 3

One of the best open-source 3D printers currently on the market is the Creality Ender 3. What distinguishes it from its competitor is its fast and efficient hotbed.

It has a dependable power supply that provides enough power to heat the bed quickly and uniformly. This ABS 3D printer’s build surface is one of its best features. It shields the heated bed from different elements.

This feature also contributes to the durability of the 3D printer; the heated bed stays clean and smooth.

After a power outage, the ABS 3D printer can resume printing. Creality Ender 3 comes with a Y-axis frame design of 40 x 40 inches.

Uses:

- Saves you a great deal of time as the hotbed needs only 5 minutes for heating up to 110° Celsius

- The build surface ensures 3D printing of high quality for a variety of materials

- You can assemble this printer quickly and easily. The process should not take more than a couple of hours, as you have to fix 20 nuts

- It uses the most advanced extruder technology. The extruder is upgraded to avoid the risk of plugging. It is V-shaped and has POM wheels. This makes it less noisy and durable.

- The Creality Ender 3 has ideal ABS filament characteristics

- Printing resumes from the point of interruption

- V-shaped extruder results in quiet operation

- Easy to assemble, thanks to the illustrated guide

- A user-friendly LCD interface makes it easy to use

- Cable harnesses may feel a bit cheap

- The guide does not include well-written explanations

|

SeeMeCNC Rostock Max V4

An American company based in Indiana manufactures the Rostock Max series, which is the market leader in desktop delta printers, based on a RepRap design from 2012 and several variations, including the Kossel.

One of the main selling points of the Rostock Max V4 is its delta design, which is somewhat uncommon in 3D printers.

It’s quite fascinating to watch the print head move around while printing. The three arms of this open-source 3D printer slide up and down in unison make it appear almost magical when in operation.

The Rostock Max V4 comes with a standard 32-bit Duet Wi-Fi board. It also has a touchscreen controller and auto-leveling capabilities. It consists of a large build volume, which is greater than typically considered in large format for desktop printers.

The size of the printer is 430 x 410 x 910 mm. It uses a nozzle of 1.75 x 0.5 mm and prints with a speed of 350mm/s. It has a layer resolution of 0.01 mm along with a maximum bed temperature of 110°C.

Uses:

- Suitable for 3D printing as a hobby as well as professional use

- Ideal for engineering projects and prototyping as it can print strong, industrial-grade materials, such as nylon

- Restock Max V4 can handle any task you throw at it while running smoothly and quietly

- The lighter Bowden print head moves faster and more easily than any Cartesian counterpart. This results in faster and smoother printing.

- Delta robot 3D printers are sometimes difficult to calibrate. However, they also provide tangible benefits.

- The Rostock Max V4 is an excellent choice in general. It has the added benefit of being open source.

- The large, improved heated bed

- The SE300 auto-leveling hot end ensures reliability and repeatability, ensuring each print comes out flawless

- Massive build volume

- Can print from a mobile device

- Extreme precision

- The extruder head is upgradable

- The price is reasonable for what it provides

- Top feed filament works well

- Most filament materials can be printed

- Bulky frame

- The unit is quite slow

Monoprice Mini Delta

The Monoprice Mini Delta is one of the best budget open-source 3D printers on the market, with excellent precision of up to 50 microns and a printing speed of 150 mm/s.

The size of the print bed is 220 x 220 x 240 mm. It offers a minimum layer thickness of about 100 microns. The Monoprice Mini Delta is a fantastic open-source 3D printer with a low price tag!

Uses:

- Comes pre-assembled and ready to use

- Because of the heated bed, you can print ABS and other more difficult 3D printer filaments as well

- Prints using Wi-Fi as well as a USB or SD card

- It consists of a sturdy metal frame, which improves part print quality by anchoring the printer down. Therefore, external factors, such as vibrations, do not affect quality.

- Starts printing right out of the box

- Delivers high-quality prints

- Easy to transport

- Auto bed leveling is not good

- Intermediate users may find it overly simple

|

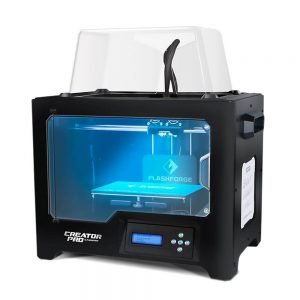

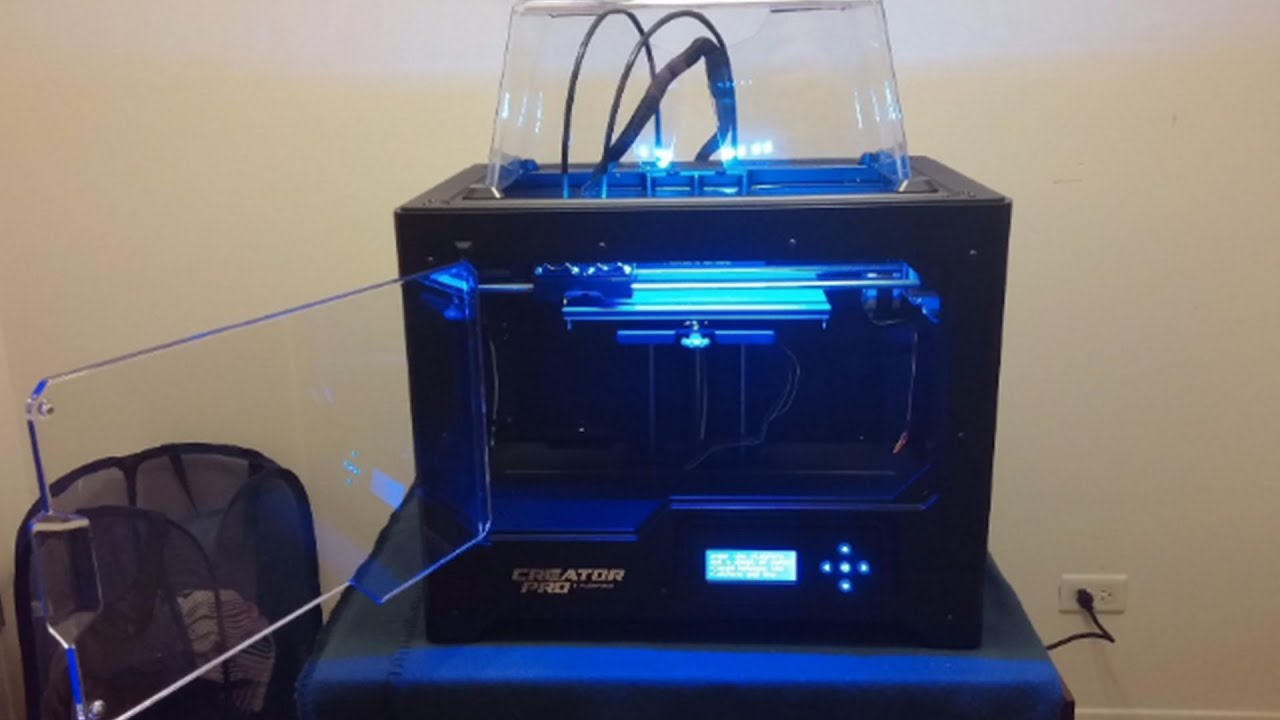

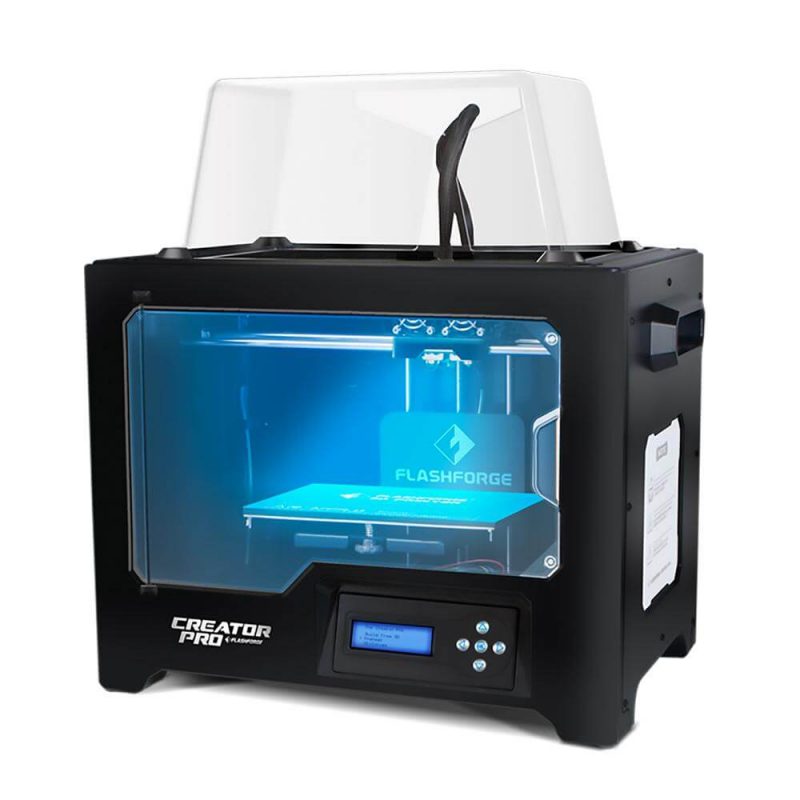

Flashforge Creator Pro

The Flashforge Creator Pro is a low-cost 3D printer with a sturdy metal frame. This open-source 3D printer produces high-quality prints.

The Creator Pro is based on MakerBot’s open-source Replicator. The Creator Pro comes has useful features. These include dual extruders, a metal build plate, and a guide rod.

One of our favorite features is the new guide rod, which significantly improves stability and durability.

It has a build area of 225 x 145 x 150 mm, but the lower price justifies the smaller build area. It prints with a layer resolution of 100 to 500 microns and has a filament diameter of 1.75 mm.

Uses:

- The Flashforge Creator Pro is most suitable for hobbyists and consumers, and for small to medium-sized businesses looking for a 3D printer for rapid prototyping

- This 3D printer is suitable for users of all skill levels. However, beginners to 3D printing may encounter a few issues that may cause them a headache

- There is a large online community of user groups, videos, and forums. You can use it to quickly resolve any issues you may encounter.

- The printer is compatible with parts from a variety of vendors. This makes it simple and easier for you to repair or improve your machine.

- It has a heated build plate and a completely enclosed build chamber. It enables multi-material printing of temperature-sensitive materials that would otherwise warp.

- Active and supportive user base and is also reasonably priced

- Comes mostly pre-assembled

- Average print quality

- 24/7 customer support

- Affordable

- Noisy

- Adjustments and upgrades required

- The difficulty may occur in the initial steps of setting it up, but the community is always there to help you out

|

Creality CR 10

The Creality CR 10 is a large Cartesian 3D printer with a separate control box and faster stripes. It has a massive build area of 300 x 300 x 400 mm. There are even larger versions with 400 mm and 500 mm-cubed print areas.

The CR-10 offers great value for money. It includes a heated glass print bed that allows you to print in PLA and ABS.

The CR-10 employs a Bowden extruder, which is incompatible with flexible filaments, such as TPU.

The CR-10 hot end has a PTFE liner and a maximum temperature of 260oC, which means that you can’t print with exotic filaments without upgrading.

Uses:

- You can use the CR-10 to print large models in one piece

- The large glass print bed offers great consistency and longevity

- The CR-10 can only work with PLA and ABS

- The amazing enhancement is the print bed of Creality CR 10, featuring special ceramic-coated glass. When warmed up, the filaments adhere well to the print bed. It eliminates the need for glue or tape. When the prints cool, they simply pop out on their own.

- The standard build volume outperforms a majority of printers

- Simple to assemble

- Simple design and few moving parts make troubleshooting simple

- Can handle large prints

- The print bed is made of removable glass

- Easy to use control panel

- The bed takes time to heat up

- Doesn’t work well with materials depending on consistent heat

- The filament holder is prone to tangling

- Extruder placement is awkward

Buyer’s Guide

Before getting an open-source 3D printer, you need to consider a few factors. Here we discuss several of the most important features.

- High Printing Quality: Every 3D printer manufacturer wants to get the highest quality prints with their machines. The technology and budget choices result in differences in performance levels. You might not get these features if you are on a limited budget. However, you can save some bucks on the print costs with 3D printer kits, and get a great 3D printing device.

- Company’s Support: In addition to all technical requirements, efficient support is vital. You should consider the quality of support offered by the company. You should seek out warranties as well as offline support, round the clock. You do not want to face any issue with your 3D printer, with no way to handle it immediately.

- Speed and Volume: If speed is important to you, look for a printer that produces a smooth finish to remove the need for post-processing. Furthermore, if you want to print multiple parts at the same time, choose a printer with a large build volume.

- Reliability: Regardless of the features you get in a 3D printer, you should not compromise on reliability. What if the 3D printer works for a few days and then stops performing well as once it used to? What if the 3D printer you bought occasionally stops working? You should expect consistent results. You can check out online communities to learn about the reliability offered by different models before you select one.

- Heated Bed: A heated bed plays an important role in improving the bonding strength of the initial layer. It keeps the bottom of the print hot, allowing for the wrap-free formation of the printed model.

Frequently Asked Questions (FAQs)

Can I Build My Own 3D Printer?

Yes, you can purchase a 3D printer kit or design and build one from scratch. Kit 3D printers are typically less expensive because the manufacturer saves on assembly costs. You can assemble and calibrate a majority of kits in a single day.

What Are 3D Printing Filaments? Why Are They Used?

The filament is the material used by a 3D printer for printing. In FDM printers, the material is in the form of a filament wound around a small spool. A guide tube feeds the filament into the extruder. Thermoplastics for 3D printers that use the FDM method are typically in the form of filaments.

Material pellets are used instead of filaments in some 3D printers, mostly industrial ones. This significantly reduces the cost of 3D printing material. Other 3D printers, i.e. SLA printers, use liquid resin rather than thermoplastic strands.

Which Materials Can’t Be 3D Printed?

It’s difficult to imagine a material that can’t be 3D printed. Theoretically, almost any material can be 3D printed under the right conditions, with the exception of liquids.

However, you will have to modify the printer’s settings to print with liquid, as well as make sure the temperature of the room is above 0oC. Other materials, such as natural gases, cannot be 3D printed under normal circumstances.

Which Printers Are Better: Open Source Or Closed Source?

There is a heated debate regarding Open Source vs. Closed Source! Every project must strike a balance between open source and closed source.

Some people prefer fully open-source hardware, while others want a plug & play machine.

Closed-sourcing machines encourage innovation toward specific markets, whereas open-source elements attract a community. It enables incremental improvements to the system.

Developers often don’t want to go completely open-source, but you also want community input. Therefore, this is a trade-off towards going open-source and finding optimal solutions together. Overall, open-source 3D printers are a win-win!

Conclusion

Open-source 3D printers are flexible to upgrade as needed.

The Anet A8 comes as a kit and can work with materials like ABS and PLA seamlessly!

The Original Prusa i3 Mk2 is best for hobbyists and home users with noiseless operation.

The LulzBot Mini 3D printer is ideal for you if you want to see high-quality prints faster. BCN3D is most suitable for printing large models.

The Ultimaker 2 Go is easily transportable and delivers high-quality prints, while the Creality Ender 3 can resume printing from the point of interruption.

The Flashforge Creator Pro has awesome user-friendly features. Its community is also supportive. Furthermore, the low price point of open-source 3D printers allows the end-users to access these printers easily.

Whether you are an enthusiast, a professional, or a home user, you can print with unlimited possibilities. For this, all you need is to select the best open-source 3D printer!