Worldwide

Filter

Showing 61–90 of 260 results

PROS:

- No-hands on production concept.

- Printing happens at room temperature.

CONS:

- There is no gallery wherein pictures of parts and functional prototypes are displayed which gives you a little more idea about the accuracy that the company is stating all along.

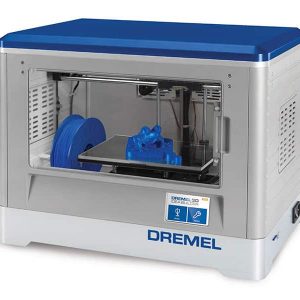

PROS:

- Easy to use

- Compact and affordable

- Fully assembled

- Decent quality prints

- The easy bed leveling process

CONS:

- Runs only with Dremel PLA filament

- Do not provide WIFI connectivity

PROS:

- Print removal is easy.

- 30 percent faster than 3D40.

- Reliable 3D printing.

CONS:

- Oozing of the filament is a bit of a problem.

PROS:

- The printer is easy to set up and use

- There is an excellent print quality that the printer produces, whether it’s a part of a functional prototype, regardless of the industry you wish to use it in, it will deliver up to the mark

- The printer sets in front of the world a perfect example of safety and reliability. Often those two are considered counterparts of each other and the printer that has the former lacks the latter. But with Dremel Digilab, the manufacturer has proven that both can be present in almost equal amounts

- 3D45 has a comprehensive ecosystem that is tailored for education

CONS:

- Whenever you are printing in this printer using a third-party filament, you’d notice that the print quality is lower than what it was

- Although it can print with some materials that are advance when you typically turn on to materials like Nylon, the printer starts to show some tantrums

- The closed system that this printer has limited creativity to an extent

PROS:

- Auto Calibration

- Moving print bed

- Accuracy and detailing in minute parts and their edges

CONS:

- Resin bottles are to be bought from the company

- The price of the printer makes it look un-affordable to the experimental beginner in the field of 3D printing

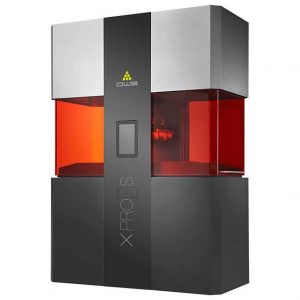

PROS:

- This printer's company is a leader in making additive manufacturing technology 4.0.

- Compatible with a wide range of DWS proprietary resins.

- Has the ability to produce transparent materials, nano-ceramic materials, and materials that are used to make investment casting models.

CONS:

- It is a single laser system.

- Post Processing Requirement.

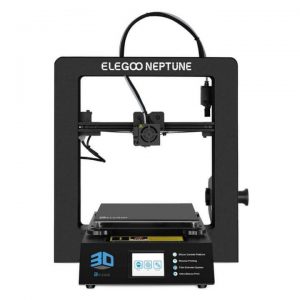

PROS:

- The 3D printer is simple to setup

- You can achieve high-quality print quality

- Compatible with a variety of materials

- Comes with titan extruder

- It has the glass carbide build plate

- Enough space for printing

- Includes necessary accessories to complete the setup and start 3D printing

- The SD card has the Elegoo Cura

CONS:

- Bed Leveling isn’t that easy

- Not assembled

PROS:

- Easy to operate

- Sleek design

- Plug and play

- High precision

- Comes with one year warranty

- Twice as fast as traditional methods

- Parts look and feel like traditional gypsum models

CONS:

- Very expensive

- Smaller build space

PROS:

- Intricate detailing of parts possible.

- User friendly.

- Industrial-grade 3D printing possible.

CONS:

- Small build volume.

PROS:

- Offers you printing with a lot of printing materials.

- You can print with four different build sizes and four different voxel preferences using P4K Series.

- The quality of parts manufactured using the printers is excellent.

CONS:

- The build size of parts and functional prototypes is very small.

PROS:

- It provides 10 times faster speed than other DLM machines

- It provides high-resolution printing

- Plug-and-play technology helps in easy operation

- The user-friendly interface provided with the screen touch system for ease of setting the printing parameters

- Compact and can be accommodated in small space as well

- Reduced need for the support structure

CONS:

- It is expensive

- Not accessible for those with low budget

- Post-processing requirement

PROS:

- There is a separate tab of success stories that tell about which printer was used in which industry to generate what!

- If you plan to be an EOS customer, there is a lot to gaze all over the website and learn from.

CONS:

- The website is too long. And, so if you are not used to navigating in a proper fashion, you might get lost!

PROS:

- Excellent management of various aspects of 3D printing process is possible using various parts of this 3D printing system.

- No need for any support structures.

- An extraordinary quality of parts and functional prototypes for various applications are possible using this 3D printing system.

- You can choose from a variety of different 3D printing materials.

CONS:

- The high cost of printing per part when compared with other 3D printing technologies.

- Relative to other melted parts, DMLS parts are porous and their porosity can be controlled but not eliminated in the 3D printing process during post-processing.

PROS:

- Huge build volume.

- Four different laser sources for melting and fusing, leading to consistency in the overall surface of the part or functional prototype.

- Multi-material printing.

- Good quality part and functional prototypes.

CONS:

- Requires huge one time investment.

PROS:

- Four high-power laser sources to ensure coherent melting and fusing of metal powder and excellent surface finish in parts and functional prototypes.

- Sophisticated material management and software systems for ease of use and operation after, before, and during the 3D printing process.

- Ability to print with various 3D printing materials.

CONS:

- Buying EOS M400-4 or even leasing it, requires a huge one-time investment, monetarily as well as in training and operation.

PROS:

- High-powered laser

- Laser Power Monitoring with Gas Management System

- Stand-alone automatic powder-sieving

CONS:

- The cost of the printer is something many might have a problem with.

PROS:

- Helps to achieve amazing print quality with high strength.

- Offers a huge range of materials.

- Supports third party slicing software.

CONS:

- Post-processing of every part and the functional prototype is required.

PROS:

- Capable of creating the most complex parts.

- No debinding is required.

- A furnace was built for the office.

- Two-step bound metal printing process.

- Allows users to print any part thickness.

CONS:

- The printer and sinter furnace are two different machines, managing both of them can be quite difficult even for professionals.

- The cost of the printing machine is a lot on the higher end.

PROS:

- Patented quality for 3D printing of parts and functional prototypes.

- Highest build volume offered.

- Adjustable print speed.

CONS:

- The price of the printer would be judged as on the higher end by the users of technology like FDM and SLA.

PROS:

- High-speed process for additive manufacturing.

- Large available envelope for substantial size parts.

- No melting characteristics.

- Bonding of dissimilar metals.

- Metal matrix composites.

- Smart or reactive structures.

- Low-temperature process.

- Complex internal geometries.

- Requires no post-processing on parts and functional prototypes.

CONS:

- Cost is a huge issue with every industrial printer and Fabrisonic Sonic Layer 4000 falls in that range. So no one can help it when users are more concerned about cost than quality and quantitative manufacturing in less time.

PROS:

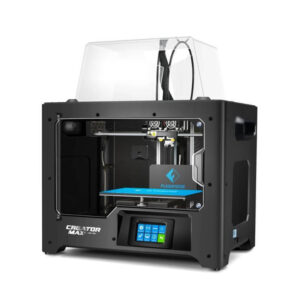

- Comes with dual extruders

- You can connect using USB and micro SD cards

- Allows use of third party filaments

- It is open-sourced

- The print bed is completely removable

- It has a touch screen interface

- Allows printing with various materials

CONS:

- Pro 2 has an open body because of which it can be subjected to danger if kids are around

- The temperature of the atmosphere will affect the overall quality of the print so some complex geometries can not be printed with dimensional accuracy

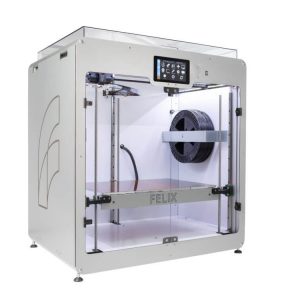

PROS:

- Comes with swappable print heads.

- Has a dual extruding system.

- Parts and prototypes of larger volumes can be printed using Felix Pro 3.

- Accommodates a touch screen on its top for monitoring and controlling.

- It comes with multiple options to connect.

CONS:

- The printer has an open body because of which temperature stability is an issue.

- The safety of parts, while they are in the printing process, is also an issue.

PROS:

- Huge build volume.

- Intuitive touch screen interface.

- Wifi-connectivity.

CONS:

- Enclosed chamber printing.

PROS:

- Huge Build volume.

- Removable and bendable flexplate.

- Dual extrusion system.

- High-quality surface finish.

- Dimensional accuracy even in intricate parts and functional prototypes.

CONS:

- Enclosed print chamber.

- Post-processing of part is difficult because cooling takes more time than in any open-body 3D printer.

PROS:

- Optional dual extruders.

- Flexible build plates.

- Semi-automatic leveling.

- Heated bed.

CONS:

- Open body.

PROS:

- Third-party filaments are supported in the printer

- The printer has a user-friendly touchscreen display

- There’s a filament runout sensor in Adventurer 3 that’s coupled with a resume print feature that allows parts to resume printing exactly from the same point from which they were left off after changing filaments

- Multiple connectivity options in Adventurer 3 include USB, Wi-Fi, ethernet, and cloud printing

CONS:

- The build plate can move around too much and sometimes cause the part to fail so it has to be calibrated before printing which takes a lot of time every time!

- The instruction manual that comes with this printer can be confusing to get through

- The Wi-Fi connection is known to present some issues while updating the software

PROS:

- Independent dual extrusion system.

- Built-in camera.

- Can be monitored from anywhere.

CONS:

- Compact in size, small build volume.

- Enclosed body.

PROS:

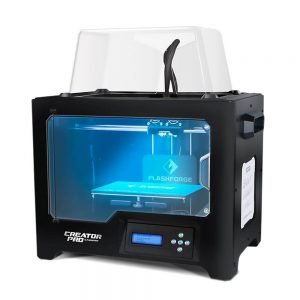

- Dual extrusion.

- Considerable build volume.

- Easy to set up.

- Decent print speeds.

CONS:

- Printing support materials is a little confusing.

- It’s difficult to deal with the SD card slot and there are complaints about the way it functions.

PROS:

- Pre-Assembled

- Decent Print Quality

- Dual Extruder

- Affordable

- Heated Bed

CONS:

- No Auto Calibration

- A Bit Noisy