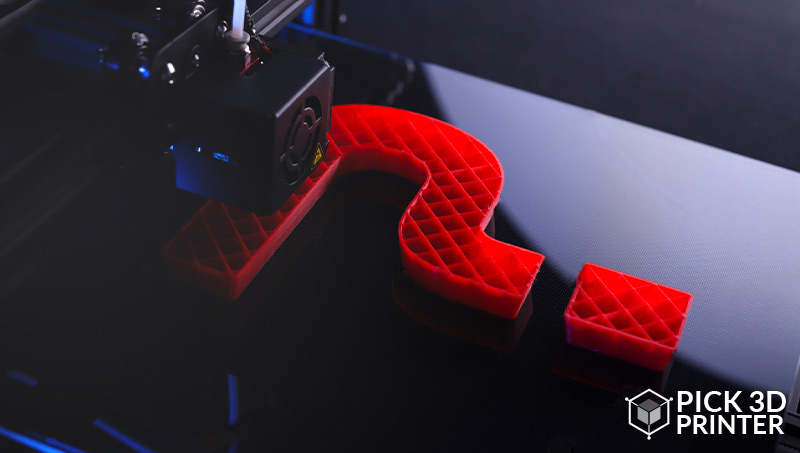

3D printing technology, also known as Additive Manufacturing or Rapid Prototyping, is a manufacturing process that converts a digital 3D model into a solid object by depositing material layer by layer.

There are different types of 3D printing technologies. These include Fused Filament Fabrication, Stereolithography, Selective laser Sintering, Digital Light Process, PolyJet, and Electron Beam Melting, etc.

In this article, we will focus on Fused Filament Fabrication (FFF) technology and list down the best 3D printers based on it.

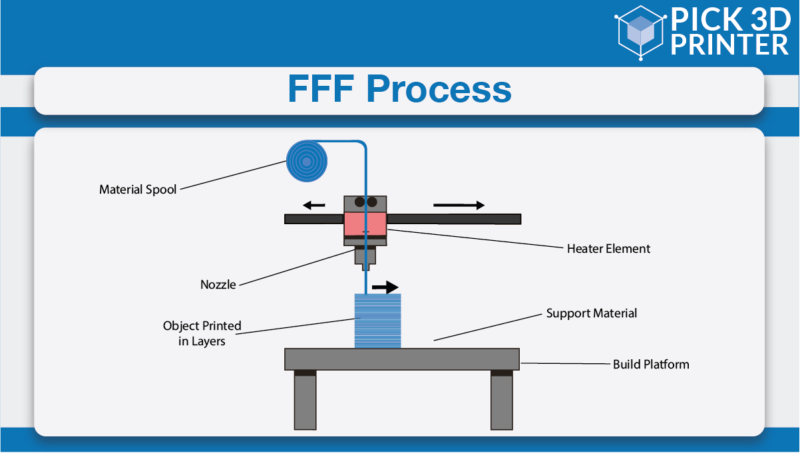

Fused Filament Fabrication (FFF)

The Fused Filament Fabrication or FFF is a material extrusion process that creates a 3D object by depositing molten filament layer by layer on a build plate. The deposition occurs in a specific way by the slicing software.

The term Fused Filament Fabrication is also often referred to as Fused Deposition Modeling (FDM) as there is no such difference in their additive manufacturing process.

FDM was invented by Stratasys in 1989. It was used to produce industrial-grade 3D printers. The entire printing chamber was heated up to 90 degrees to create a 3D part through a material extrusion process. Later, in 2009, its patent expired. However, Stratasys maintained its trademark.

RapRep came up with a new name (FFF) for similar technology to use to produce low-budget desktop 3D printers without violating the copyright law before the patent expired.

FFF 3D printers were designed without a heated chamber in order to be as cost-effective and value-engineered as possible. This movement enabled a wide range of consumers to access 3D printing technology as its price dropped ten times. Now, even home users and hobbyists can easily own it.

After the expiry of the patent, other companies also came up with 3D printers that had heated chambers for quality printing. Since then, the terms ‘FDM’ and ‘FFF’ started to mean the same.

Now every manufacturer uses the words ‘FDM’ and ‘FFF’ for all 3D printers that extrude and use thermoplastic filaments despite having a heated chamber or not.

Advantages of FFF 3D Printers

FFF-based 3D printers are widely used in various industries for manufacturing parts, rapid prototyping, and educating. These include automotive, architecture, aviation, learning institutions, and even the food industry.

Home users and individuals also acquire these as they are more economical as compared to other 3D printers. Their prices are comparatively low.

Moreover, they use materials that are widely available and cost less. This further reduces your production cost. Moreover, there are a wide variety of materials with which these printers are compatible. These include plastic polymers, mixtures of wood, ceramics, carbon, and metal, etc. There are colored filaments available and they can be customized.

The FFF technology is easy to understand and handle. It is ideal for beginners, small business owners, and students who have little technical experience.

Lists of the Best FFF 3D Printers

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Original Prusa i3 MK3 | 9 points auto calibration | 7.9 | |

| Creality Ender 3 | Budget Friendly | 7.2 | |

| Lulzbot Taz Workhorse | Next Generation tool head | 7.7 | |

| Zortrax M300 | Plug and Play | 8.8 | |

| Makerbot Replicator Plus | Fastest | 8.8 | |

| Ultimaker 3 | Workhorse | 9.2 | |

| Modix Big 60 | Runner up | 9.1 | |

| ZMorph VX | All in One | 7.7 | |

| Monoprice MP Maker Pro Mk.1 | User Friendly | 7 | |

| Raise3D Pro 2 | Precise | 8.7 |

Original Prusa i3 MK3

|

The Original Prusa i3 MK3 is the successor of its award-winning predecessors. It also gained popularity among customers due to its new extruder system and other updated features.

The printer is open source with a build volume of 250 x 210 x 200 mm and a PEI coated removable print bed. You can connect to it through a USB port or an SD card. It uses proprietary software for slicing and is compatible with MAC, Windows, and Linux. It comes both as assembled and a DIY kit.

The kit costs $900. You can buy the kit and assemble it yourself to save money.

Uses:

- It is a great option for beginners and serious learners as there is a lot to learn from assembling and operating it.

- You can create miniatures for fun and sell those for money.

- The new extruder placement enables easy changes of the nozzle without the need of redoing the whole assembly line and improves print quality by minimizing resonance and enabling better cooling of the parts.

- The optical filament sensor is reliable and is compatible with all types of filaments.

- Due to quiet operation, you can use it in homes and small offices without disturbing others.

- You can use a third-party filament to minimize the material cost.

- Power recovery

- Open-source

- Third-party filament

- 9 points auto-calibration

- Quiet operation

- Requires assembling or have to pay extra for fully assembled one

- Poor layer adhesion

- Open frame

Comgrow Creality Ender 3

|

The Creality Ender 3 by Comgrow is a gem. It offers advanced features that not even expensive 3D printers offer at an extremely low price of around $200. It is easy to handle and a very compact device with a build space of 220 x 220 x 250 mm.

The printer has a nozzle with 0.4 mm diameter and 200 m/s speed. The maximum layer resolution is 0.1 mm. You can connect it through a USB port or an SD card. The machine comes semi-assembled. You are required to set it up before starting to print.

Uses:

- It has a heated print bed that offers proper adhesion of the first layer and enables using tricky materials like ABS, PLA, TPU, and PETG.15512

- The power outage recovery function stops printing when there is a power failure and resumes it from where it stopped after the power comes back.

- You can use third-party filament as it is open source.

- It can be used in offices and homes without disturbing others due to its quiet operation via the TMC2208 stepper motor.

- Very cheap

- Easy assembling

- Adequate print space

- Open-source

- Good resolution

- Quiet operation

- Fast

- Compact design

- Manual calibration

- Hard to do bed leveling leading to print failure

Lulzbot Taz Workhorse

|

Lulzbot 3D printers have always been reliable and powerful. They are open source and allow printing with a wide range of materials. These have impressed various users and professionals.

Lulzbot Taz Workhorse has a 14% larger build volume with various advanced features. It offers better output quality and highly accurate results. It has a build volume of 280 x 280 x 285 mm with layer resolution that varies between 0.05 to 0.4 mm.

The machine costs $2950.

Uses:

- It is designed for professional use. It can be used in niches such as automobile, aerospace, and medical industries, etc.

- The printer has a heated borosilicate glass print bed that is coated with PEI. It helps in better adhesion of the first layer and allows printing with materials like nylon.

- The studier frame of the machine offers stability during printing.

- You can print with a wide range of materials due to the steel tool head. These also include strength composite polymers and high heat composite polymers.

- It is able to print with great accuracy and precision due to the hardened steel E3D Titan Aero hot end along with 360-degree cooling.

- In addition, the automatic nozzle cleaning and auto-calibration make it user-friendly and ease out the task of users.

- The users can control all the settings through a 3.5 inches graphical LCD. It is beginner-friendly.

- Its modular print bed system quickly heats up the print plate further enhancing the versatility of the machine.

- Due to the open design, it gives a complete view of the print progress and works best with materials like PLA.

- The printer uses a next-generation tool head that is swappable.

- Accurate

- High speed

- Auto calibration

- Auto nozzle cleaning

- E3D extruder

- Swappable tool head

- Expensive

- No Wi-Fi connectivity

- No remote access

Zortrax M300

|

A Polish company, Zortrax has gained a lot of fame for continuously contributing to the additive manufacturing niche market. It aims to offer a complete ecosystem that includes great 3D printers along with a wide range of materials and an in-house slicing application to its consumers.

M300 by Zortax is easily accessible and offers high-quality results. The printer has a build volume of 300 x 300 x 300mm with a nozzle of 0.4mm. The layer thickness varies from 90 to 290 microns. It is inbuilt with a filament run-out sensor, three cooling fans, and other features that inspire people in every walk of the profession.

The machine costs $3590.

Uses:

- It is best for serious buyers and creators. It serves businesses in a wide range of applications.

- It is safe to use this printer due to its enclosed chamber. The closed frame also allows printing with tricky materials by maintaining a consistent temperature inside.

- The automated bed leveling eases calibration for beginners.

- You can remotely monitor the 3D printer through WI-FI due to the inbuilt camera.

- You can control the machine through an intuitive 4 inches touchscreen that is easy to operate. It allows users to preview the 3D model before printing and make necessary changes.

- The machine is also compatible with third-party filament Thus; it enables you to manage the production cost.

- HEPA filter helps to filter out harmful dust particles and fumes up to 99%. Thus, making it safe to be used in a closed and less ventilated area.

- The enclosed frame makes it safe

- Eco friendly

- Easy to set up

- Plug and play

- Wi-Fi connectivity

- Remote monitoring

- Pricey

Makerbot Replicator Plus

|

Makerbot Replicator Plus is the improved version from the Makerbot 3D printers’ family. It is quieter and has many unique features that make it stand out among other printers of a similar price range. The device is 25% larger and 30% faster than its predecessors. It has a black sleek body with an open frame.

The printer has a large built volume of 6.5 x 11.6 x 7.6 inches and weighs 18.3 kg. It is easy to set up. You can connect to it through WI-FI or USB. It is compatible with Makerbot Software, which is user-friendly.

You can have a hand on this professional machine by investing only $2499. The company offers great customer service after the purchase.

Uses:

- Makerbot Replicator Plus is best for architectures to create precise models, small businesses for general 3D printing, and trainers for teaching 3D printing.

- Due to hollow sides, front and top, it allows you to keep an eye on the printing process.

- You can easily control the printer’s settings through a control panel that is located at eye level. There is one push button wheel and two other buttons that help in navigating the display. Before printing, that preview of the design can be easily viewed on a cellphone or desktop.

- It enables you to choose between 30 different filaments. The filament is stored externally which enables you to check its level of usage and easily load and unload it.

- Buy a smart extruder with the printer to keep track of the low level of filament.

- The machine produces straight lines with perfection. It is good for 3D printing complex geometric structures and sculptures.

- Sturdy body

- Large print space

- Easy to set up

- Wi-Fi connectivity

- Decent output quality

- Remote monitoring

- High speed

- Bit pricey

- USB connectivity issues

- Nonheated print bed causes warping

- Cannot use third party filament

- Open frame poses a risk of burning upon touch.

Ultimaker 3

|

Ultimaker 3 is a workhorse that exceeds all the expectations and is used for various specialized purposes. It is a next-generation machine with astonishing features. It requires low maintenance and is easy to operate. It allows you to create complex designs at a high speed with great accuracy.

The printer has dual extruders with a large build space of 215 x 215 x 300 mm and a maximum speed of 300 mm/s. It has a nozzle of 0.4 mm diameter that can print with a resolution of up to 20 microns. It uses Cura for slicing, which is open-source software. You can connect to it either through a USB port, WI-FI or LAN.

It will cost you only $3500 for this extraordinary printer.

Uses:

- It is great for small businesses that want to scale up their production. It is used in the aerospace, medical, and jewelry industries to produce highly detailed parts.

- The printer can operate for hours without any hassle.

- Due to dual extruders, it allows you to print with two colors and materials simultaneously.

- The machine is also compatible with PVA, allowing you to create a support that is water-soluble.

- You can remotely control and operate the printer through WI-FI connectivity, cloud access, and an inbuilt camera.

- It offers plug-and-play features an automatic calibration to ease out beginner’s tasks.

- It is compatible with the third-party filament; both standard and premium.

- Open-source

- Dual Extruder

- Accurate

- Hot swappable print core

- Low maintenance

- Expensive

- Open design

Modix Big 60

This printer comes from Modix Large, launched in 2017 as a DIY Kit. You can now find the third version of this machine on the market. This 3D printer is available for $3700.

Uses:

- You can use this printer for research, restoration, as well as prototyping in a variety of industries

- The models are easy to remove thanks to the print bed, which is removable

- The fast print speed reduces your production time

- You can connect the printer to multiple devices

- Compact footprint

- Large build volume

- Reliable

- Easy to operate

- Requires assembling

ZMorph VX

|

If you are looking for an ‘All in One 3D printer, ZMorph VX is a great option to be considered. It offers various functions with great features. It comes with two extruders and one printing head that can have a diameter from 0.2 to 0.4 mm.

The printer has a build volume of 250 x 235 x 165 mm and layer resolution from 25 to 400 microns. The machine costs $2800 and comes with a one-year warranty. However, you can extend it to two years by paying a further $699.

Uses:

- You can use it to do 3D printing, laser engraving, and CNC milling.

- It is a multi-tool 3D printer that has CNC pro, and laser pro tool heads.

- The printer helps in mass printing. It holds up to four filament rolls. The dual extruders will use two rolls at one time and the other two are kept as backups.

- You can use different materials. These include plastic, ceramic, chocolate, or dough.

- The touch screen offers an easy user interface to control and monitor the printing process.

- It enables precise and accurate printing with automatic bed leveling.

- High print quality

- Versatile

- User friendly

- Efficient

- Automatic bed leveling

- Costly

- The print head usually get clogged

Monoprice MP Maker Pro Mk.1

|

MP Maker Pro Mk.1 is the last 3D printer introduced by the company. It resembles Wanhao Duplicator D9 in many ways. It comes fully assembled by the company and has an open sturdy aluminum black frame.

The printer has a print space of 300 x 300 x 400 mm and a speed of 70 mm/s. It has a nozzle of 1.75 mm, an intuitive LCD screen, and is compatible with Cura. It requires an investment of $339 only.

Uses:

- It enables you to start a small venture by producing large-size parts and functional prototypes for aerospace, jewelry, and miniatures for the toy industry or teaching children.

- The open frame allows for consistent airflow that helps to cool down the object simultaneously for better accuracy.

- The machine itself detects the filament run-out and indicates it to the user by pausing printing.

- It is also great for beginners due to automatic calibration and magnetic removable print bed.

- You can use third-party filament and print with ABS, PLA, and PETG.

- Huge build space

- Easy to use

- User-friendly interface

- Magnetic build plate

- A sturdy frame minimizes vibration

- Slow speed

- Not for temperature sensitive materials

- Risky to use around children

Raise3D Pro 2

|

Raise3D Pro 2 has raised the bars for others. It provides the consumers and prosumers with all the features they need for day-to-day work. It has all the great features of its predecessors along with other improved ones. It is appealing to all those who tend to seek professional experience.

The printer has a build volume of 305 x 305 x 300 mm with a speed of 150 mm per second. It comes pre-calibrated and fully assembled. You can connect through WI-FI, LAN, and a USB port.

The machine costs $3999.

Uses:

- It is used for a wide range of applications from producing prototypes to end products. In addition, it is compatible with various materials. This extends the possibilities to a greater extent.

- The printer has a dual gear-driven extruder that is 50 percent faster than those in predecessors. It includes an enhanced filament grip that offers reliable extrusion of material.

- It enables you to create precise and highly detailed geometric structures with a minimum resolution of 0.01 mm.

- HEPA filter helps to filter out harmful dust particles and fumes up to 90%. Thus, making it safe to be used in a closed and less ventilated area.

- The machine indicates when the filament is running low and pauses printing for the user to refill it.

- When there is a power failure the printing pauses and the print process is saved. After power recovery, printing resumes from where it stopped. This saves from huge losses.

- You can remotely monitor the 3D printer through WI-FI due to the inbuilt camera.

- Supports multiple materials

- High precision

- Reliable

- The heated and removable print bed

- Enclosed chamber

- Eco friendly

- Expensive

- Large in size

- Tricky slicing software

- Difficult user interface

Buyer’s Guide

There are numerous factors one should consider when buying a FFF 3D printer. These include:

High Nozzle Temperature

The temperature that a nozzle can sustain determines which materials you can use to print. The higher the temperature, the printer is compatible with a wider range of materials and can print with tricky materials like nylon.

Heated Print Bed

The heated build plate offers better adhesion of the first layer and enables you to print with tricky materials like ABS.

Auto Bed Leveling Feature

The auto-calibration eases users’ tasks and prevents print failure.

Print Speed

The size of your model, the complexity of design, and the material used determine the speed of your 3D printer. However, you should look for one that prints fast as it will save your production time.

Build Volume (Width X Breadth X Height)

The larger the build volume, the bigger models you will be able to produce. If you want to produce large size parts, then you should consider a printer with a huge build space. Otherwise, you will have to produce different small parts of an object and assemble them later. This will affect your product’s quality.

Price of Printer

It is one of the most important factors to be considered. It depends on your budget and how much you can invest to buy a 3D printer.

Frequently Asked Questions (FAQs)

Are FFF 3D printers expensive?

FFF 3D printers are comparatively cheaper than other 3D printers like SLA or DLP. Moreover, they use low-cost materials. Thus, this further reduces the production cost.

What material do FFF 3D printers use?

They usually use filament of thermoplastic material such as ABS, Nylon, and PLA, etc to print parts or functional prototypes.

How to choose the best 3D printer filament?

The filament is the food of your product. A sustainable filament will increase the life of your output and a bad filament will impact your brand name. Therefore, you should search thoroughly about those before purchasing in bulk. You can even ask for samples from a few companies for trial.

Can I produce multi-color objects with a FFF 3D printer?

Most FFF 3D printers can only print in one color. If you want to produce multi-color 3D prints, then you should buy one that has dual extruders and allows you to print with at least two colors simultaneously.

Conclusion

The market for 3D printers is expanding exponentially. There are hundreds of FFF3D printers available. Each of them has its own pros and cons. You cannot get the desired results until you find one of the top-performing FFF 3D printers that best fit your printing goals. So, carefully check out the above-listed printers and then make your final discussion.