Modern 3D printers are capable of performing specific functions. A ceramic 3D printer features industrial additive manufacturing systems.

These systems may vary from printer to printer as ceramic 3D printing involves various processes, including binder jetting and powder sintering. Ceramic 3D printers generate parts that require heavy post-processing.

This guide includes a comprehensive selection of ceramic clay 3D printers tried and tested by our experts.

What is a Ceramic 3D Printer?

A ceramic 3D printer offers a high level of detail while printing. The way a ceramic 3D printer works depends on the technology installed in the printer. A ceramic 3D printer features multiple technologies, such as SLA, DLP, LCD, and so on.

The printer employs these technologies to create crisp and high-resolution models at a high speed. These technologies, however, do differ in the way they print ceramic models.

While FDM is a process commonly used to produce clay and ceramics, processes such as SLA and binder jetting produce more accurate ceramic models.

Uses of a Ceramic 3D Printer

Ceramic materials come with many desirable properties, which is why a ceramic 3D printer can have multiple uses. Having a ceramic 3D printer at your disposal can help create various ceramic products. You can use a ceramic 3D printer for

Ceramic Art, Pottery, and Sculptures

Traditionally, pottery and sculpture making is a delicate process that requires a lot of time and patience. With a ceramic 3D printer, you can achieve intricate and complicated designs in no time.

You can use the printer to create art including pottery and sculptures. Moreover, you can also create ceramic items, such as vases, watches, or even ceramic jewelry, using the printer.

Biomedical

There are a number of applications with ceramic 3D printing when it comes to the field of medicine. Medical processes can require complicated tools.

A ceramic 3D printer allows you to produce high-quality tools that are consistent and accurate for every stage of the process.

The printer allows you to work on tools and devices that you can customize to serve individual patient needs.

Manufacturing

Ceramic 3D printing has a wide variety of applications in various industries, including aerospace, automotive, chemical, electrical, and environmental.

With the customizable functions of the printer, you can experiment with various designs. You can also use this multifunctional tool for immersive learning and advanced research in many fields.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| StoneFlower 3.0 | Strong and Sturdy | 9.8 | |

| ExOne X1 160Pro™ | Premium Pick | 9.6 | |

| Formlabs Form 3 | Strong and Practical | 9.5 | |

| Delta WASP 2040 Clay | Most Functional | 9.5 | |

| ZMorph VX | Most Reliable | 9.3 | |

| CeraFab S Series | Editor’s Choice | 9.8 | |

| Tethon3D Bison 1000 | Honorable Mention | 9.3 | |

| Admaflex 300 | High-quality | 9.7 | |

| 3DCeram C3600 | Industrial Printer | 9.0 | |

| KWAMBIO Ceramo Two | Runner-up | 9.7 | |

| 3D PotterBot Scara v4 | Best Usage | 9.1 | |

| Cerambot Cerambot | Best Value | 8.9 | |

| VormVrij LUTUM 5 | Most Practical | 8.8 | |

| XJet Carmel 1400C | Strong and Durable | 9.1 | |

| Lynxter S600D | High-Temperature | 8.7 |

List Of Best Ceramic 3D Printers

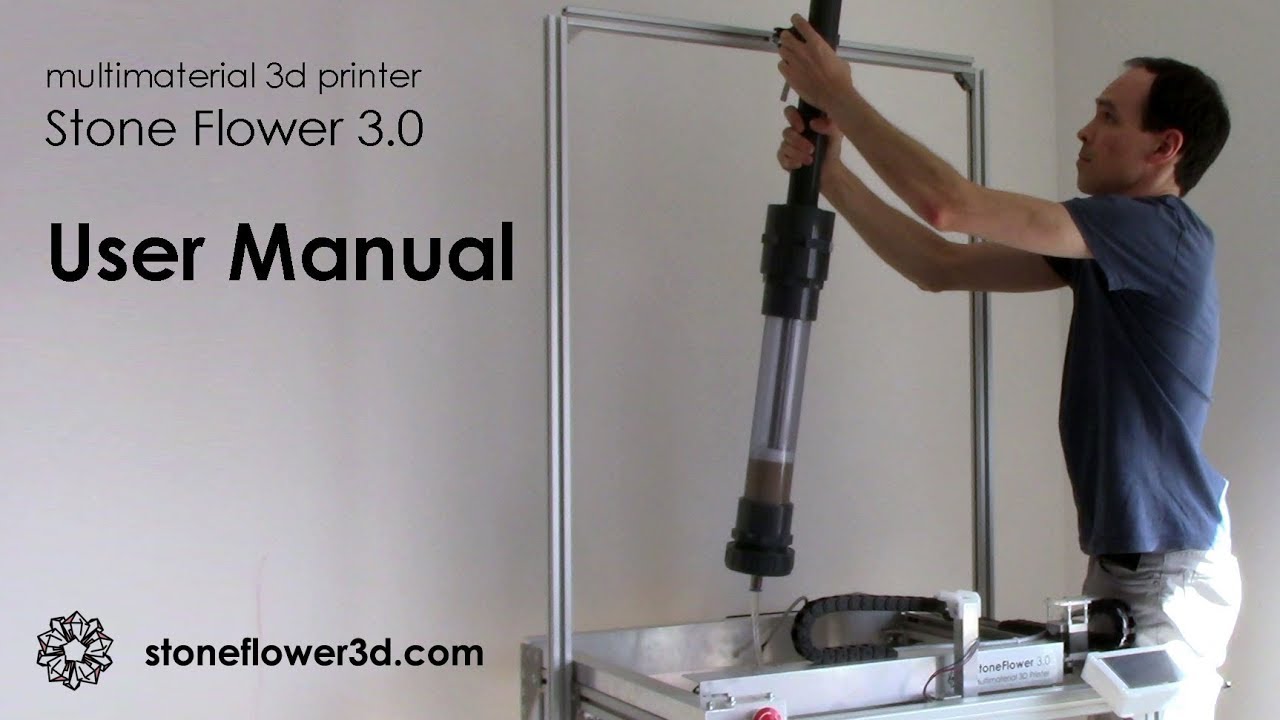

StoneFlower 3.0

|

The Stone Flower 3.0 is a ceramic 3D printer suitable for prototyping and small production of all kinds, including arts, design, architecture, and more.

The printer comes with an impressive build volume of 480 x 480 x 500 mm, and it can produce large-scale products.

The printer not only produces ceramics and porcelain products but can also work with materials, such as plaster, pulp, wax, and even soldering paste.

The printer consists of an extruder that allows it to adapt to third-party materials. The Stone Flower 3.0 also comes with a tray that you can place anywhere freely.

The ceramic 3D printer has an emergency stop button that allows you to cancel the printing process in case of any emergency.

The printer also comes with IGUS bearings that prevent damage to the printer from dusty and humid conditions. These bearings do not require any regular lubrication and are easy to maintain.

Salient Features:

- This printer is equipped with modern technology, such as a 5″ touchscreen control panel and Wi-Fi. These features make for easier operation.

- The 3D printer has a closed enclosure, which keeps the device dust proof.

- Network compatibility through Wi-Fi, USB, and Ethernet cable.

- Easy to assemble and it takes less than 30 minutes to put the printer together.

- The 3D printer has some latest technological advancement, which ensures an excellent user experience.

- Easy to assemble

- Compact footprint

- Affordable option

- Doesn’t have clear operating instructions

- Temperature generation requires improvement

ExOne X1 160 Pro

|

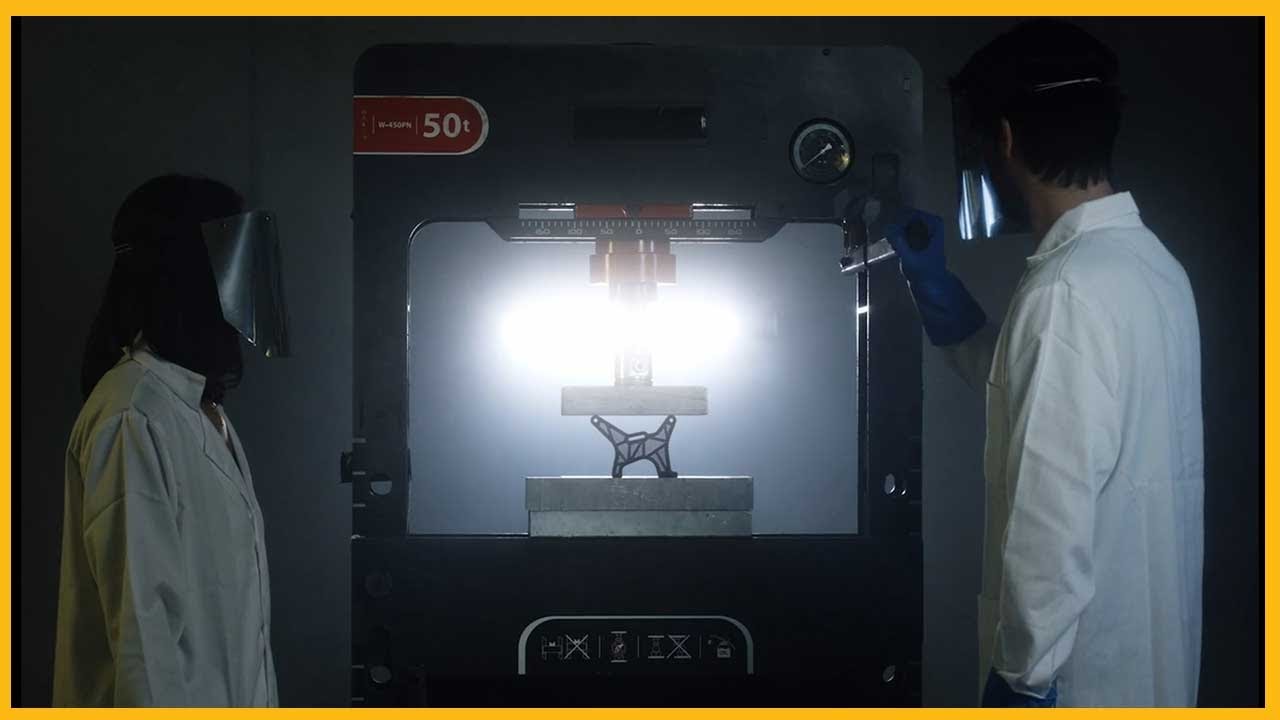

German manufacturer company ExOne is best known for its 3D printing systems. Its ceramic 3D printer 160 Pro is one of the best-known ceramic 3D printers.

Using the binder jetting technology, the X1 160 Pro is capable of printing different types of ceramic, such as alumina, silicon carbide, and materials often used in the medical and aerospace industries.

The 160 Pro has a huge build volume of 800 x 500 x 400 mm, which makes it large enough for mass-scale production, such as producing investment casting parts. The layer thickness for the printer lies between 30 and 200 μm.

The printer functions with ExOne Scout, a secure Industry 4.0 app that allows you to monitor your machine in real-time. The app also provides an analysis of 3D production.

This printer is ideal for users doing business based on binder jetting technology.

Salient Features:

- The printer has a wide material flexibility as it can print more than 20 metals, including ceramics

- Balances printing speed and printing quality pretty well as the speed can reach up to 10,000 cm3/hour

- Patented quality features that deliver industry-leading density and repeatability

- X1 160 Pro is a great option for those who want to produce manufacture industrially

- High print resolution

- Accurate designs

- Easy to set up and handle

- User-friendly interface

- Accompanying products can be expensive

Formlabs Form 3

|

The Formlabs Form 3 is a stellar ceramic 3D printer, which has become hugely popular in the manufacturing world owing to its professional prowess.

Magnificent on the outside, the inside of the printer houses SLA technology based on Low Force Stereolithography. This technology results in superior texture objects.

Employing ceramic resins, the Form 3 ceramic 3D printer allows you to produce precise and detailed ceramic parts easily.

Form 3 has a build volume of 145 x 145 x 185 mm, which allows it to cater to high consumer needs. The large resin 3D printer employs a large 5.5-inch touchscreen for a hassle-free user interface.

With a range between 25 and 300 microns, the printer offers accurate printing at a high resolution.

Salient Features

- Allows real time monitoring and cartridge sensors to the introduction of a new form of resin

- The closed compartment body makes it a safe choice

- Supports a wide range of printing materials

- An advanced form of SLA, known as Low Force Stereolithography

- Closed body for added safety

- Can support multiple users and printers at a time

- Great quality prints at fast speed

- Expensive

ExOne X1 160 Pro

|

German manufacturer company ExOne is best known for its 3D printing systems. Its ceramic 3D printer 160 Pro is one of the best-known ceramic 3D printers.

Using the binder jetting technology, the X1 160 Pro is capable of printing different types of ceramic, such as alumina, silicon carbide, and materials often used in the medical and aerospace industries.

The 160 Pro has a huge build volume of 800 x 500 x 400 mm, which makes it large enough for mass-scale production, such as producing investment casting parts. The layer thickness for the printer lies between 30 and 200 μm.

The printer functions with ExOne Scout, a secure Industry 4.0 app that allows you to monitor your machine in real-time. The app also provides an analysis of 3D production.

This printer is ideal for users doing business based on binder jetting technology.

Salient Features:

- The printer has a wide material flexibility as it can print more than 20 metals, including ceramics

- Balances printing speed and printing quality pretty well as the speed can reach up to 10,000 cm3/hour

- Patented quality features that deliver industry-leading density and repeatability

- X1 160 Pro is a great option for those who want to produce manufacture industrially

- High print resolution

- Accurate designs

- Easy to set up and handle

- User-friendly interface

- Accompanying products can be expensive

Delta WASP 2040 Clay

|

Entering the ceramic printing industry, WASP produced one of the leading ceramic 3D printers. Delta WASP 2040 Clay is an extrusion-based delta machine specifically designed for clay printing.

Using material extrusion, the machine has an extrusion system that consists of an output pressure multiplier of up to 40 bars. The printer also has an optional retraction system.

The printer is extremely versatile as you can use it to print any soft paste material that you can extrude under 4-6 bar pressure.

For precision, the printer uses a 1mm nozzle. The printer also has a generous build volume of 200mm x 400 mm and retains a printing speed that can reach up to 300 mm/s.

For accuracy, the printer uses LDM (Liquid Deposition Modeling) extruders.

With Wi-Fi compatibility, the Delta WASP 2040 Clay is operatable even from long distances. You can also control the printer remotely. You can customize the settings to your preferences.

The printer has a resurrection system composed of a resistive divider. The divider maintains the power input in the printer and allows it to function properly without any hindrance.

Salient Features:

- Resumes printing in case of a power failure from the point it stopped

- Compatible with all major 3D slicers

- The build platform ensures high-quality 3D printing for a variety of materials

- User-friendly, thanks to a super intuitive LCD interface

- Allows for mass production with repeatable designs

- Solid and sturdy build

- Open design for easy monitoring

- Expensive

- Not ideal for use at home

ZMorph VX

|

The Z Morph VX printer is not like other ceramic 3D printers as it is a plastic FDM 3D printer that is capable of producing ceramic parts.

The Z Morph VX can perform various functions, including CNC milling, laser engraving, and other tool-head-enabled functions.

This ceramic 3D printer can also print other materials using its thick-paste extruder. The printer has a large build volume of 530 x 555 x 480 mm that enables it to work well in industrial ceramic production.

Featuring robust and sturdy construction, the Z Morph VX is an ideal tool for dynamic and versatile printing. The printer features interchangeable tool heads, a paste extruder, and a dual extruder, which allows it to print variably.

The Z Morph VX also lets you perform multi-tone printing with its dual pro tool head. This feature lets you print multiple materials at a time for a wide range of results. This printer is a multi-tool solution to your industrial needs.

The printer also has an efficient design that allows it to hold four rolls of filaments at a time. This makes filament switching easy during the mass printing process.

Salient Features:

- The modular heating element heats up the area when experiencing a clog for easier cleaning

- This printer is compatible with all the printing materials available in the market

- Highly durable

- The magnetic print bed allows easier switching from CNC carving to 3D printing

- Allows auto-calibration

- High-quality technology that allows for above-average print quality

- Unmatched printing speed

- Allows you to use various types of materials for printing

- Easy removal of media

- Can be printed from computer using Wi-Fi

- Efficient design

- Expensive option

Cera Fab S Series

|

When it comes to ceramic additive manufacturing, Cera Fab has made quite a name for itself. The French company developed a ceramic 3D printer based on a stereolithography process. The process allows the ceramic layers to harden layer-by-layer using laser technology.

The S series ceramic 3D printer has a large build volume of 600 x 600 x 300 mm, making it suitable for large-scale production.

The printer consists of four lasers and a resolution of 30 microns over the entire surface. The printer can print different kinds of ceramics, including alumina and silica.

Moreover, the printer photopolymerizes these materials layer after layer. The S series ceramic 3D printers have an ergonomically advanced design.

The printer allows you to operate it comfortably while allowing accessibility as well. The printer has barrier-free access to the inside of the machine. You also get an unobstructed view of the inside to help you monitor the printer process.

The S series ceramic 3D printers have a cascade system with four production units. This allows you to manufacture four different models simultaneously.

These production units are protected and partitioned so that the printing process is not disturbed in any of the units.

The printer also makes use of the WQXGA projectors for high resolution. This allows for finer prototypes.

Salient Features:

- Optional water-cooled LED light source for cleaner visuals of the installation

- The printer comes completely assembled

- High printing quality with the ability to produce intricate designs at the ends and edges and curves due to the light source used by the machine, which does not spread that easily and stays focusedHigh resolution printing

- Wide range of functional materials for prototyping and production

- With multiple features, this ceramic 3D printer is a top pick for industrial production.

- Delivers consistent and reliable production

- Easy resin loading feature

- Large build volume for mass production

- High functioning software

- The machine is a bit on the pricier side

Tethon3D Bison 1000

|

The 3D Bison 1000 from Tethon has an impressive build volume of 110 x 60 x 130 mm along with 57-micron pixels. Its layer thickness is adjustable and can be set at 25, 50, or 100 microns.

The printer has a 1920 x 1080 FHD resolution. The printer is compatible with various materials, including Porcelite, Ferrolite, Castalite, Vitrolite, and more.

Salient Features:

- Heated chamber temperature can reach a maximum of 80 degrees

- Can work with two different build plates .e. PEI or PP

- Interchangeable tool head allows for easy switching

- Can create complex geometries with superfine details

- Enclosed design for safety purposes

- Can be calibrated automatically

- User-friendly touchscreen interface

- Sleek and stylish appearance.

- All-in-one 3D printer with high performance

- Low printing noise levels

- Produces high-quality prints

- Easy connection to your devices

- Printing speed is average

Admaflex 300

|

Specializing in 3D printing techniques, Admaflex came up with the Admaflex 300. The printer relies on stereolithography and uses the DLP process for ceramic printing.

The printer mixes the ceramic powder with liquid resin to produce ceramic models. The Admaflex offers a build volume of 200 x 200 x 300 mm, with a layer thickness in the range of 10 to 200 µm.

This printer is a modular machine, which means that you can adjust its printing volume and resolution easily to work on different projects.

The Admaflex 300 also features a patented feedstock system. The ceramic 3D printer has an integrated high-volume material handling system that allows it to print large components.

This feature is accompanied by automatic vision-controlled dosing. The printer effectively handles high viscosity materials, which means greater reliability and higher speed for the production process.

The feature also allows the reusing of the excess material, thereby reducing waste.

The Admaflex 300 is also an open system that provides full printing control to the user. The printer allows the user to customize the settings before and during the printing process.

The settings can also be stored on a centralized data server for easy preparation.

Salient Features:

- The printer allows for a quick and easy material switch and is also able to process multi-material printing

- An in-process monitoring system that observes temperature, humidity, and foil usage

- Sensors that receive warnings and pause the print automatically when a problem occurs

- The Admaflex 300 is a first-rate printer, which is quite popular in the world of manufacturing. Its ability to produce quality prints makes it one of a kind.

- Super accurate and precise in function

- Easy to use, which makes it suitable for beginners

- Increased efficiency output

- Easy to customize functions

- High printing cost

3DCeram C3600

|

The 3D Ceram C3600 is one of the best ceramic 3D printers available today. The printer comes with an impressive build volume of 600 mm x 600 mm x 300 mm.

The large build volume allows you to use the printer for the mass production of ceramic models. The printer is also capable of processing rare ceramics, such as zirconia, alumina, and a range of other materials.

You can use the C3600 to develop advanced ceramic parts in different industries, such as aerospace and medical.

The C3600 features four laser sources that allow it to offer printing time that is ideal for industrial needs. With a high printing speed, the C3600 printer uses stereolithography printing technology for high printing quality as well as the accuracy of the printed parts.

This ceramic 3D printer uses Support Free Link technology that enables you to build models without leaving support marks. The C3600 is also adaptive to serial 3D printing as it opts for a co-operation method.

Salient Features:

- Uses a fast technique that results in high-speed printing

- Comes fully assembled with an easy setup procedure

- Uses SLA technology combined with laser for the printing process

- Excellent print quality

- Highest speed in the industry

- Requires minimal cleaning

- Large print volume and formatting with its massive build volume

- Maintenance and running cost is high

Ceramo Two

|

If you are looking for a reliable ceramic 3D printer, the Ceramo 2 is an ideal option. The printer has a build volume of 400 x 250 x 400 mm with a minimum layer thickness between 50 and 200 micrometers.

Apart from this, the printer offers layer resolution up to 600 dpi. Each print head jet has a capacity of 500 and 1000 respectively.

It also has an impressive speed of 1000mm/sec, which allows you to speed up the manufacturing process.

This printer is ideal for mass-scale production as it can easily accommodate continuous printing of prototypes.

With a glass-based powder, you can shorten the manufacturing process using the Ceramo 2. Ceramo 2 uses Inkjet Binder Technology that allows it to print in high quality.

The ceramic 3D printer does not use a syringe mechanism for deposition. Instead, it takes a binder jetting approach, as the machine is equipped with a 128 nozzle print head.

The water-based binder helps in the formation of the model in a layer-by-layer process.

With its advanced features, this printer is surely a steal.

Salient Features:

- The printer is compatible with a wide range of materials. This allows you to be flexible in terms of production.

- In case of a power failure, the printer’s resume print function allows you to start from where you left off.

- Compatible with Windows XP and Vista 7-10, with IP network connectivity.

- Provides fast printing with accuracy

- Easy to assemble

- Decent build volume

- High-quality printing

- User manual needs to be more detailed

3D PotterBot Scara V4

|

You can consider the 3D Potter Bot series a truly dedicated ceramic 3D printer. This printer is ideal for pottery making. With a build volume of 254 x 254 x 305 mm, the printer can output large volumes of ceramic models.

The printer comes with a sizable ram extruder, which allows it to maintain continuous flow as well as precise printing. Unlike other ceramic 3D printers, the 3D Potter Bot series gets rid of the usual hose feedstock system, which causes lag.

The printer, instead, features constant extrusion resulting in precise printing throughout. The 1000 ml extruder doesn’t use any external power sources or air compressors.

The printer also has a competing print speed of 35 to 60mm/s. The 3D Potter Bot Series uses its direct extruder to print real ceramic directly. The 3D Potter Bot can also print via Wi-Fi.

Salient Features:

- Easy to use touchscreen user interface to perform various function including importing graphic and customizing your model

- Requires no maintenance or high-cost materials

- Sophisticated harmonic drive units that cause no backlash or jittery movements while printing

- Layer to layer printer that allows complex designing as well

- Quick layering time

- Simple, easy-to-use workflow

- Also offers Wi-Fi connectivity for easier control

- Open design for easy monitoring

- Easy post-processing

- The temperature generation is slow and needs to be improved

CeramBot

|

The CeramBot printer is an affordable ceramic 3D printer that is ideal for beginners and hobbyists.

This printer comes with two different types of extruders where the pro extruder allows you to make adjustments through the LCD screen and the air extruder requires you to adjust the pressure manually for printing.

The company also offers a version where you can have both extruders at the same time.

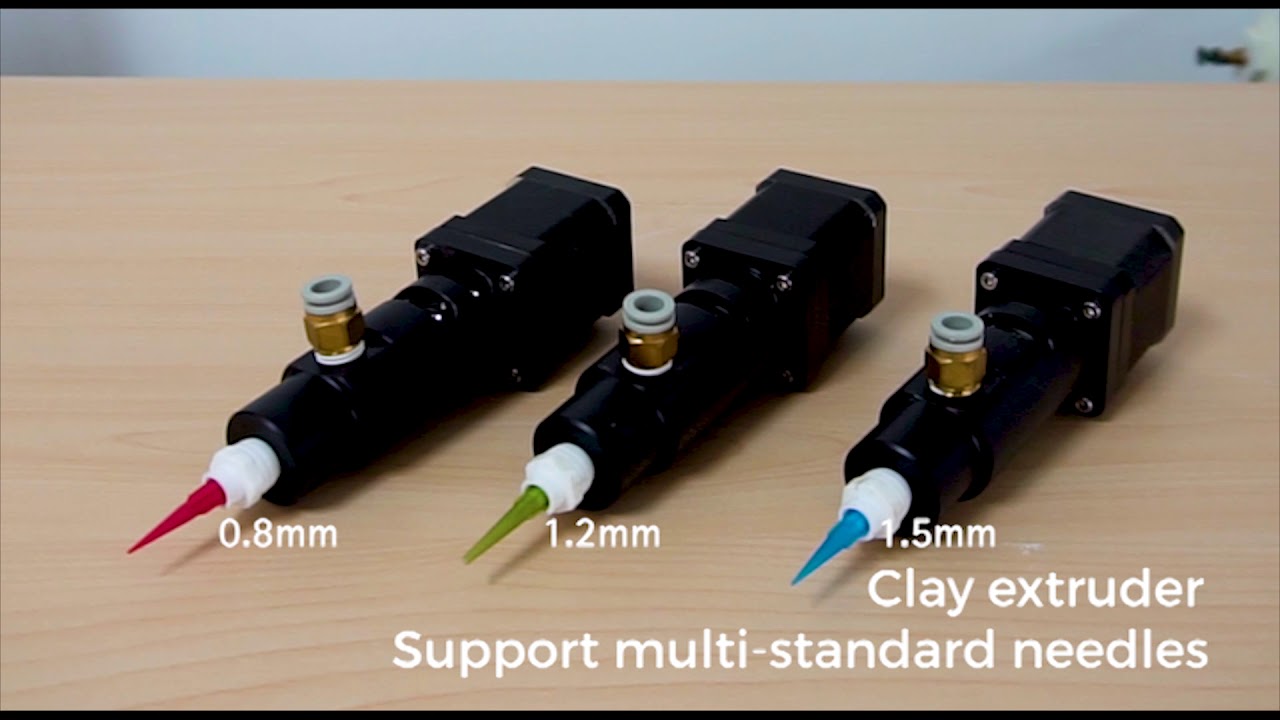

The CeramBot printers have an exceptionally high speed that is 20% higher than their counterparts. The printer comes with different nozzle diameters that range from 0.8 to 2 mm.

This printer works with materials such as clay, which is inexpensive and eco-friendly. The CeramBot has a unique motor design that enables it to work without any air compressor.

The motor works in a way that guarantees print quality and stability even when you are printing complex designs. The motor also eliminates air bubbles while printing.

Salient Features:

- The aluminum and steel structure makes it solid and sturdy while guarantying stability and precision

- This printer is compatible with most software and slicing tools

- Delta design that enables it to print large and tall objects

- Comes fully assembled so you can use it right out of the box

- Affordable option

- Customizable and adjustable printing settings

- Can be printed from a computer using Wi-Fi

- Efficient design

- Not recommended for industrial use

VormVrij LUTUM 5

|

Manufactured by a Dutch company, the VormVrij LUTUM is one of the best ceramic 3D printers. The printer has an air pressure system that helps the clay transport easily from a cartridge with a volume between 0.65 and 8L.

After transportation, this clay is extruded. You can easily control the pressure settings with a single manual control system and a corresponding large 128 × 64 LCD screen.

With this ceramic 3D printer, ceramic printing becomes more accessible. The printer has many applications in different fields, including industrial use as well as medicinal use.

The printer has a build volume of 430 x 460 x 510 mm, which is quite impressive. The printer has arranged its internal electronics in an enclosed box for better protection against the outside environment.

Salient Features:

- Solid and sturdy build with more strength, balance, and weight

- Compatible with most software and slicing tools

- High printing speeds between 20 mm/s and 100 mm/s

- Easy to operate as it allows settings to be adjusted

- Easy to maintain

- Comes fully assembled

- Can be connected to other devices using Wi-Fi

- Efficient and solid design

- Produces high-quality prints

- Printing speed can be improved

XJet Carmel 1400C

|

The Carmel 1400C is a ceramic 3D printer launched by XJet. This printer uses NanoParticle jetting to produce ceramic 3D models.

This method consists of additive manufacturing that employs liquid dispersion to form 3D printed parts rather than using melted powder.

Because of this technology, the resulting products are detailed and produced with high levels of accuracy. This ceramic 3D printer has a build volume of 500 × 280 × 200 mm that allows it to manufacture multiple parts simultaneously.

Carmel 1400C is known for its medicinal uses as it helps develop bone replacements and more.

Salient Features:

- The printer can print separate nanoparticle fluids for versatile metal and ceramic parts

- One of the largest build trays that enables it to print extremely fine layers, down to only a few microns thick

- Can create complex geometries with superfine details

- Easy operation due to a user-friendly interface

- Structurally and architecturally well-built

- Can print complex and high-quality models

- Sleek and graceful design

- Easy to operate software that can also be accessed through the cloud

- Printing speed can be improved

Lynxter S600D

|

The Lynxter S600D is a high-temperature ceramic 3D printer recommended for professional use. This printer has a delta design with a build volume of 390 x 600 mm.

The S600D printer can support multiple materials, including PEI or Nylon. This is due to its impressive heat generation. The printer bed can go up to 180°C and the extruder can reach temperatures up to 450°C.

Thanks to the high temperature, the printer can print three high-performance materials at a time. This 3D printer also prints silicone.

Salient Features:

- Heated chamber temperature can reach a maximum of 80o

- Can work with two different build plates .e. PEI or PP

- Interchangeable tool head that allows for easy switching

- Can create complex geometries with superfine details

- Enclosed design for safety purposes

- Can be calibrated automatically

- User-friendly touchscreen interface

- Print resume feature allows you to start from where you left off

- Fast heating system

- Sensors built-in for secure and dependable operation

- Requires safety precautions while using

Buyer’s Guide

As an alternative to plastic, ceramic 3D printing is quite useful. There are many things you need to look out for while purchasing a ceramic 3D printer.

Here are some of the key points, which can help you make an informed decision while purchasing a ceramic 3D printer.

- Speed: High-speed printing allows you to print many products in a limited time. This feature helps you save time. It is recommended to select a printer that allows high printing speed without compromising the print quality to get the best possible results.

- Size of the Printer: A small printer is compact and portable, which helps you save more space. The downside of a small 3D printer is that you will have limited space for making items. A larger printer offers more space for building items but requires larger storage space and an extended surface for working.

- Printing Quality: For a high-quality ceramic model, the printing quality should be exceptional. You should look for this critical feature when selecting a ceramic 3D printer.

- User Interface: An interface can change your printing experience. A good user interface helps you save time while navigating through the settings with ease. A touchscreen user interface allows you to adjust the settings easily and helps you customize your models. A good interface also allows you to see the status of your printer, i.e. how much resin is left.

- Enclosed and Open: While purchasing a ceramic 3D printer, you will come across two categories: enclosed and open. An open model printer does not have anything surrounding the build area, unlike enclosed models. An enclosure has its benefits as it prevents contamination, like dust, wind, and changes in temperature. An enclosed printer also prevents your room from filling up with harmful gases produced during the printing process. An enclosed printer is a suitable choice for good quality prints and safety but they can be a bit pricey.

- Budget for Ceramic Printer: The cost of the printer depends on the features you are looking for. An average 3D printer will cost anywhere from a few hundred to a few thousand dollars. If you are new to 3D printing and are not willing to spend a lot of money, a small machine that is affordable seems like a good option. However, if you are a professional, invest in a pricier printer with a wide range of features.

- The Build Volume: You have to consider the dimensions of your printer as well. A build plate is usually shaped as a square or rectangle. If you are a beginner, a small printer will be suitable. However, if you are venturing into the manufacturing business, you might need to look for a device with a larger build volume. All the printers mentioned above have a large build volume.

Frequently Asked Questions (FAQS)

What Are The Professional Applications Of Ceramic 3D Printing?

Using ceramic 3D printing, you can create a variety of products that are applicable in different industries, including medical, aerospace, art, architecture, décor, and so on.

Why Does Ventilation Matter While 3D Printing?

When your filament or resin is heated, it releases intense and reeking fumes, which may lead to irritation and headaches. Therefore, a properly ventilated room is required for 3D printing.

However, some printers already have an enclosure or a fan, which will reduce your contact from the fume extraction.

Is There A Limitation To What Shapes You Can 3D Print?

3D printing allows you to build any shape that you desire, depending on the scale. Some 3D printer models come with built-in model designs that you can use for printing. 3D printers also allow you to customize and design models.

Conclusion

There are different types of ceramic 3D printers available with a unique selling point. From the printers reviewed above, CeramBot is the most cost-effective ceramic 3D.

The Cera Fab S series printers are a strong contender for the best 3D ceramic printers that have multi-function capabilities and feature advanced engineered technology.

All these ceramic 3D printers have unique selling points and this article provides the ultimate buyer’s guide for selecting the best ceramic 3D printers.