3D printers are among the most advanced and innovative inventions of the 21st century, with their ability to create anything that we can conceive in our beautiful minds.

In the past, the closest we could get to bring a thought to reality was to draw things on paper or make them out of clay or other materials.

3D printing is a new age concept that converts a digital image to a physical model or manifestation. It only requires a design and sending it to the 3D printer, which starts whirring and bringing your design to life.

An innovative extension to the 3D printer is a carbon fiber 3D printer, which is essentially a 3D printer that uses carbon fiber to make objects other than the regular polymer filaments.

Basically, carbon fiber features a long chain of carbon atoms bonded together. It’s highly durable and has a high tensile strength, which makes it lightweight yet strong.

It’s being used for a lot of things nowadays, such as tennis rackets, arrows, bicycles, car parts, phone cases, and many other things that need to be strong and lightweight.

While typical carbon fiber has chains of 5 to 10 micrometers, short carbon fibers are used for 3D printing. These consist of chains that are short, i.e. less than one millimeter long.

They are combined with a thermoplastic that acts as the base material. This can include materials like Nylon, ABS, Polycarbonate, PLA, and other similar materials.

What is a Carbon Fiber 3D Printer?

Normally, a 3D printer features filaments made out of ABS or PLA, which are polymers. On the other hand, a carbon fiber 3D printer uses a filament made out of carbon fiber with short chains of carbon atoms bonded together.

They are different from normal 3D printers in their function, as they’re repurposed to print with carbon fiber filaments. One of the main changes is the replacement of the nozzle with a hardened steel nozzle.

Another way carbon fiber work is by using carbon fiber reinforcement, which makes carbon fiber even stronger and suitable for printing harder and more durable objects. Their strength would equal that of aluminum but at half the weight.

Carbon fiber can be mixed with different base materials, such as:

Nylon

Nylon carbon fiber is one of the most common combinations when it comes to carbon fiber 3D printers.

Nylon has high tensile strength and high heat resistance, which already makes it suitable for most objects. Since carbon fiber is generally brittle, nylon makes it more durable.

ABS

Acrylonitrile butadiene styrene, or ABS, is a strong polymer with a great surface finish that makes it perfect for use with carbon fiber.

ABS carbon is commonly used for higher-end carbon fiber 3D printers, because of its requirement of a heated build chamber.

PETG

Polyethylene terephthalate glycol, or PETG, is stronger against chemicals and is also hydrophobic, which makes it wonderful for 3D printing applications that require less moisture.

You can use it to build auto parts that come in contact with coolants or chemicals, or items that you can use in a rainy climate.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Ultimaker S5 | Editor’s Choice | 9.8 | |

| XYZprinting PartPro300 xT | Best Budget | 8.5 | |

| Delta WASP 2040 INDUSTRIAL X | Best Cooling System | 8.0 | |

| Raise3D Pro2 Plus | Best For Large-Scale Production | 8.6 | |

| Markforged Mark 2 | Runner Up | 9.4 | |

| Markforged X7 | Best Accuracy | 9.0 | |

| Makerbot METHOD Carbon Fiber Edition | Best Design | 8.2 | |

| Roboze One +400 | Best Filament Monitoring | 9.6 | |

| Roboze Argo 500 | Highest Selling | 9.3 | |

| Fusion3 F410 | Best Resolution | 8.8 |

List of Top 10 Carbon Fiber 3D Printers

The list mentioned below has the best 10 carbon fiber 3D printers currently in the market.

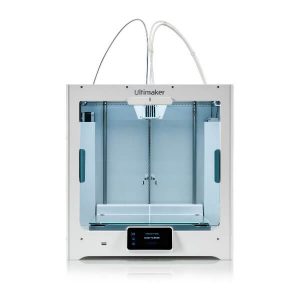

Ultimaker S5

|

Ultimaker is one of the top manufacturers of carbon fiber 3D printers and has been in the business for around 10 years. It’s renowned for providing open-source 3D printing solutions to its valuable customers.

The Ultimaker S5 is the Dutch manufacturer’s latest offering and has a build volume of 330 mm * 240 mm * 300 mm, which provides you to design and print various items.

The Ultimaker S5 is quite convenient to use, and can also be used with other filaments. With a maximum nozzle temperature of 280o Celsius, it can’t be used for many high-temperature applications, but it still makes for a great 3D printer.

This carbon fiber 3D printer comes with double extruders, as well as a removable glass print bed that’s suitable for general printing. For more complex printing jobs, you can make use of a flat anodized aluminum bed.

You can easily control the printing with the color touch screen display, and keep an eye on the built-in filament flow sensor that displays the flow after printing has begun.

The Ultimaker S5 is suitable for home-based and non-commercial projects, but it’s also used for designing and printing parts and prototypes for several industries.

Its filament flow sensor is one of the premium features that’s quite useful, especially if you do a lot of printing.

Its compact design and advanced features also let you build carbon fiber models that are strong and durable.

- Contains double extruders

- Has removable glass print bed for general printing

- Contains a color touch screen display for easy control

- Has the lowest print head temperature

- Not suitable for high-temperature printing applications

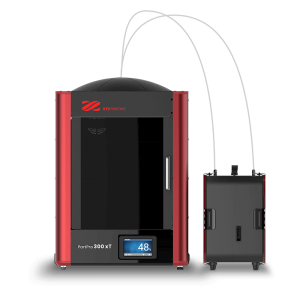

XYZprinting PartPro300 xT

|

The PartPro300 xT is a world-class carbon fiber 3D printer with high-speed dual extruder nozzles that makes it highly suitable for carbon fiber filaments and reinforced carbon fiber.

It also features auto-leveling and calibration features that ensure high precision and accuracy. Its heated chamber allows for a consistent print quality for complex designs and matrices.

Built on the FFF 3D printing technology, the printer provides two different options for build volume: 195 mm * 270 mm * 300 mm for the dual setting and 295 mm * 300 mm * 300 mm for the single setting. It also has a maximum extruder temperature of 260 to 350 o Celsius.

This carbon fiber 3D printer has space for two 3kg filament spools, which make it easy for you to use them and change the filaments less often.

In addition, a humidity control system maintains the quality of the filament and protects it from moisture. This printer helps you create top-quality parts and prototypes for numerous industries.

- Provides great print quality for complex designs

- Has auto-leveling and calibration features

- Quite affordable

- Doesn’t provide too much build area

Delta WASP 2040 INDUSTRIAL X

|

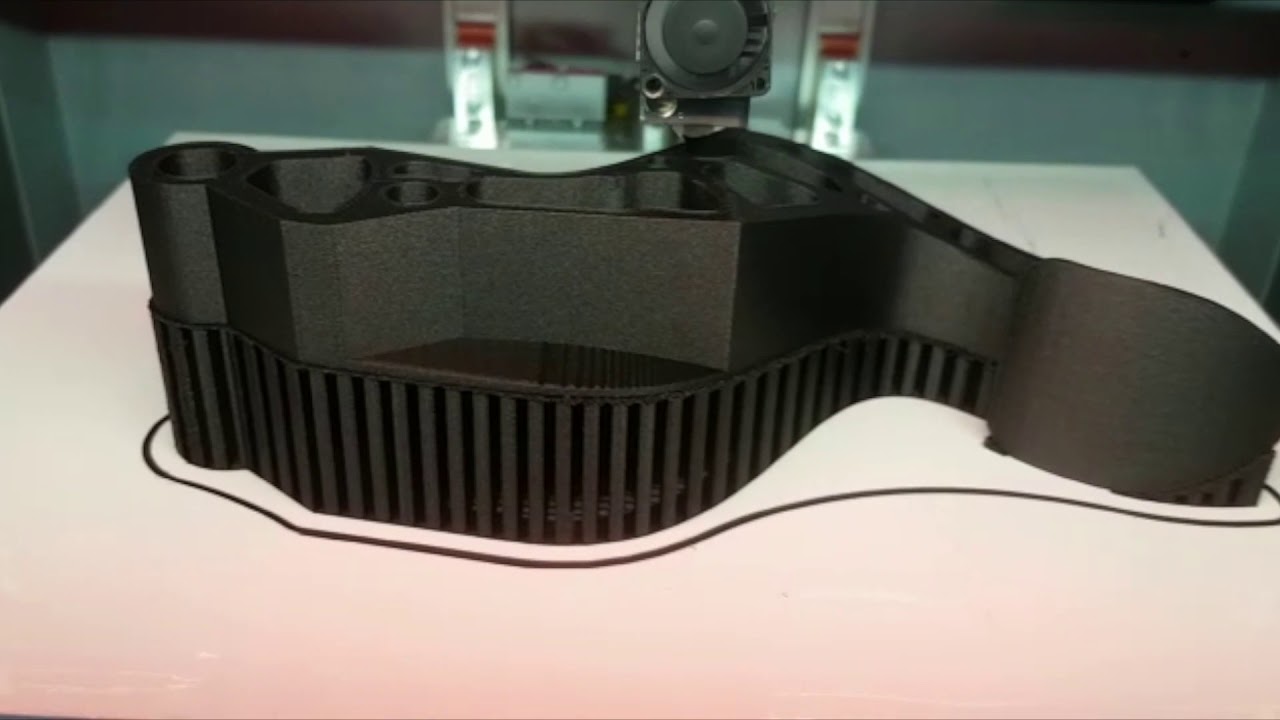

Last, but not least, the Delta WASP 2040 Industrial X is another futuristic carbon fiber 3D printer that relies on FDM 3D printing technology.

Manufactured in Italy, it allows you to use a wide range of carbon fiber composites for printing parts, prototypes, and more.

It has a signature “Hot and Cold technology” that allows you to alter the heat between room temperature and 80 o Celsius. It allows for quick cooling of the machine, which makes printing technical materials more convenient.

Its build volume measures Ø mm * 200 mm * 400 mm, as well as a minimum layer height of 50 microns. This leaves you with endless possibilities for printing all of your designs and concepts.

You can choose between two types of extruders for your carbon fiber 3D printer: the Zen X extruder, which is suitable for single and multi-material printing, and the Flex extruder, which helps you print more flexible materials.

The printer also comes with Wi-Fi connectivity and a camera that helps you control the printing remotely.

- Options to choose between single and multi-material printing

- Equipped with dual gear filament driver

- Has a user-friendly interface

- Has low-temperature generation

Raise3D Pro2 Plus

|

The Raise3D Pro2 Plus is one of the best carbon fiber 3D printers for large-format production, with its impressive build volume of 305 mm * 305 mm * 605 mm.

It offers a reliable and premium-quality printing experience that gives the best carbon fiber 3D printers a run for their money.

It also prints at a minimum layer height of 5 microns, which makes it suitable for various applications.

The Pro2 Plus has a maximum nozzle temperature of 300 o Celsius, as well as a maximum bed temperature of 110 o Celsius, which makes it highly suitable for use with carbon fiber reinforced filaments.

Even though such filaments cause a lot of abrasions, you can always equip yourself with nozzle replacements to handle the issues.

The carbon fiber 3D printer also comes with various stellar features, such as Wi-Fi connectivity. Other features include dual extrusion, print recovery, a 7-inch color touch screen, and a full enclosure.

It’s perfect for people interested in experimenting with 3D printing, as well as parts and prototypes.

Another thing that puts the Pro2 Plus in the spotlight is its affordable price point, which makes it much better than other 3D printers. It can also be used for printing with other strong filaments.

- Provides a large build area

- Has the most precise extruder nozzles

- Compatible with other filament materials

- Has a high price point

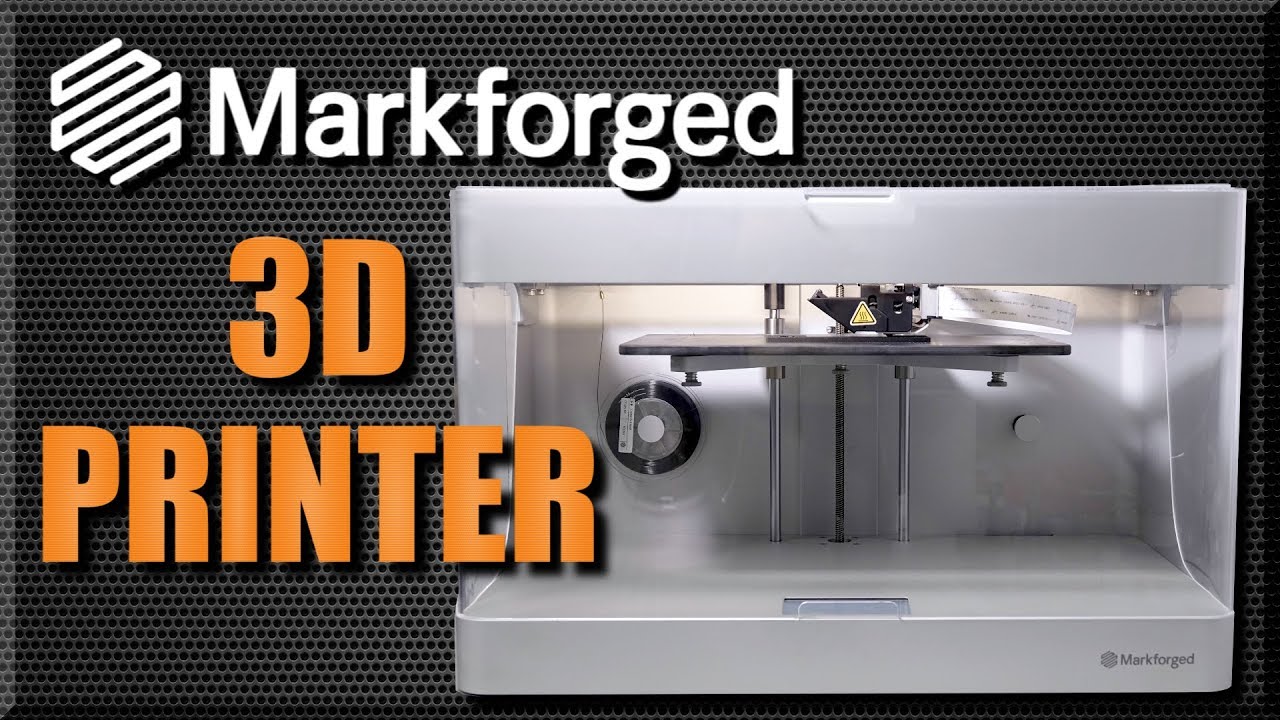

Markforged Mark 2

|

The Mark 2 by Markforged is an excellent carbon fiber 3D printer that has a wide array of excellent features, making it one of our top choices.

It uses carbon fiber reinforcement technology to build objects with higher tensile strength and durability and has a build volume of 320 mm * 132 mm * 154 mm, which provides you with a large printing area.

Mark 2 is popularly known for printing high-temperature glass fiber and Kevlar, and can also be used to create other types of wonderful and durable objects.

It’s also capable of printing at a layer resolution of 100 microns, which is quite remarkable and gives it an edge over most other carbon fiber 3D printers. It also comes with its own software, called ‘Eiger’.

Using Eiger, you can easily import and slice designs meant for high-performance production of parts and prototypes. This makes the Mark 2 an industrial-grade 3D printer with the capability of mass production.

It can be used in various industries, such as automotive, aerospace, dentistry, jewelry, defense, and many others.

According to Markforged, this is a powerhouse termed “workhorse reliability”, which means that you can keep using it to create several objects and items for the entire day and it won’t give up on you at all.

This is why Mark 2 is a strongly recommended carbon fiber 3D printer for mass production and provides versatility in build volume.

Therefore, whether you’re a 3D printing enthusiast or have an industry that could benefit from the technology, the Mark 2 is a stellar choice for either application, and it can run for a solid number of years before you swap it out with the updated model.

- Has a specialized software for importing and slicing designs

- Suitable for operating throughout the day without heating up

- Can be used for mass production

- Needs to be calibrated manually

- The price point makes it unaffordable for domestic use

Markforged X7

|

Another valuable addition from the Markforged products is the Markforged X7, which has a unique and functional design with a build volume of 330 mm * 270 mm * 200 mm and a minimum layer height of 50 microns.

This makes it suitable for building various types of parts, prototypes, and other objects.

The Markforged X7 is much more advanced than the Mark 2, also built by the same manufacturer. It’s built on the FDM/FFF 3D printing technology.

It also has some similar features, such as the ability to print using continuous reinforced carbon fiber and Kevlar, along with other parts and prototypes.

The X7 has some interesting features, like a dual nozzle system and a laser inspection process.

It has the ability to scan the prints during the process, to check for their dimension accuracy, which is crucial for evaluating critical tolerances.

Coupled with continuous carbon fiber technology, it helps create strong and lightweight parts.

It’s also equipped with a dual extruder system that allows for the layer-by-layer production of composite parts.

The first nozzle builds the plastic matrix of the design, and the second nozzle pumps carbon fiber into the matrix.

- Allows continuous printing of carbon fiber

- Has user-friendly hardware and software for ease of use

- Has a huge build volume

- A closed print chamber makes the production of large parts difficult

Makerbot METHOD Carbon Fiber Edition

|

The Makerbot METHOD Carbon Fiber Editions have a futuristic and advanced design that sets them apart from all of the carbon fiber 3D printers that you’ll find out there.

Featuring the METHOD and METHOD X 3D printers, they’re specially designed for building carbon fiber replacement parts in place of metal parts. These printers use nylon reinforced with carbon fiber, ensuring high resistance and strength.

The METHOD Carbon Fiber Editions feature a new composite extruder optimized for handling abrasive materials without any damage to the printer.

The model comprises a hardened steel nozzle, which is replaceable, along with a metal filament switch and hardened metal drive gears. It can print many carbon fiber materials, as well as reinforced carbon fiber.

What sets the METHOD and the METHOD X apart is that the former prints carbon fiber and polymer mixtures inside a 60 o Celsius heated chamber, whereas the latter prints carbon fiber and Makerbot’s signature engineering composites and polymers in a 110 o Celsius heated chamber.

- Contains carbon fiber-ready printhead

- The heated chamber provides better layer bonding

- Interchangeable nozzles have to be bought separately

Roboze One +400

|

Another wonderful carbon fiber 3D printer that’s worth mentioning is the Roboze One +400, which has a unique design and an industrial-grade extruder that can bear up to 500o Celsius of temperature without any difficulty.

This makes it suitable for many high-powered projects that expel more heat. Made by an Italian manufacturer, it’s one of the best-selling products in the market right now.

The Roboze One +400 comes with various amazing features that expand your horizon for 3D printing, and it also allows you to use reinforced carbon fiber for making different models and objects, all thanks to its high-temperature range.

The build chamber inside the carbon fiber 3D printer can easily take a temperature of 130 o Celsius with ease.

The printer has a vacuum plate system that provides better adhesion between each layer of the printed matter.

It can be termed as an industrial-grade 3D printer, owing to the fact that it provides a print area of 300 mm * 200 mm * 200 mm.

The mechanism of the Roboze One +400 works with stainless steel pinions and racks, which gives the 3D printer fluid movement and helps control the materials inside it.

The printer is wear-resistant and durable by way of a C7 ball screw on its Z-axis. Another great thing about this 3D printer is that all of its components are produced in the manufacturer’s factory using CNC techniques that allow for high accuracy printing.

If you want to try out other types of carbon fiber reinforced filaments, you can try them out with this 3D printer.

Overall, the Roboze One +400 is a reliable carbon fiber 3D printer that can be used for commercial and non-commercial 3D printing tasks with ease.

- Can withstand up to 500 degrees Celsius of temperature

- The vacuum plate system helps layers stick together strongly

- Suitable for industrial-level printing

- Costlier than other 3D printers

- The price point makes it unsuitable for home use

Roboze Argo 500

|

With its attractive design and state-of-the-art features, there’s no doubt that the Roboze Argo 500 has become one of the highest-selling carbon fiber 3D printers in the world right now. Some might even say that it’s a much more advanced version of the Roboze One +400.

Named after a ship in Greek mythology, this 3D printer can expand the scope of FDM 3D printing and bring innovation into the field.

Roboze’s Argo 500 offers you a build volume of 500 mm * 500 mm * 500 mm, which is where the “500” in its name comes from.

This provides you with sufficient printing area to build a number of parts, prototypes, objects, products, and much more.

Various industries are currently benefiting from the efficient performance of this 3D printer, some of which are automotive, aerospace, and many others.

Using this printer, you can use filaments from high-performance polymers. The options include Carbon PEEK and Carbon PA, which are hard materials.

Its extruder can withstand up to 550 o Celsius, while its build chamber can easily bear up to 180 o, thus allowing for high-powered printing.

This carbon fiber 3D printer is also great for mass production and can be used to print with reinforced carbon fiber, which allows you to print parts and prototypes that are stronger and suitable for more functional applications.

- Allows the use of other filaments as well

- Can print large parts and prototypes with ease

- Capable of bearing high temperatures

- The nozzle wears out quickly

- The extruder gets clogged up

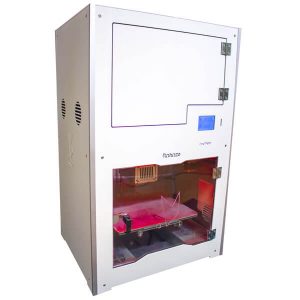

Fusion3 F410

|

Next on our list is the Fusion3 F410, an excellent carbon fiber 3D printer, which is relatively affordable than its competitors.

It has a large build volume of 355 mm * 355 mm * 315 mm and a maximum nozzle temperature of 300 o Celsius, which makes it suitable for all types of carbon fiber composite and reinforced materials.

The F410 has a state-of-the-art enclosed print chamber that provides sufficient heat to ensure that all your prints have a wonderful surface finish.

It also prints at a minimum layer resolution of 20 microns and a print tolerance of 0.003 inches, which allows you to print fine objects easily. It can also be used for mass production and large-format printing easily.

- Fast and reliable printing speed

- Can be remotely operated through the Ethernet

- Comes with interchangeable nozzles

- Doesn’t have a WiFi connection

- Less affordable than other variants

Buyer’s Guide

If you have some experience with regular 3D printers, you won’t have any trouble in exploring the various carbon fiber 3D printers that we outlined for you in this guide. You can make a better choice by following certain criteria listed below:

- Quality of the 3D Printer: Carbon fiber 3D printers have the same basic functionality as other 3D printers, most of them manufactured by companies that design and create both kinds of products. Therefore, it’s important to evaluate the output and effectiveness of the 3D printer that you’re considering buying.

- Type of Filament: Naturally, a carbon fiber 3D printer uses carbon fiber filaments to print various objects, but there are different types of carbon fiber composites that you can use for this purpose. In addition, some 3D printers allow the use of reinforced carbon fiber for printing, which results in more hardened and strong parts. So, make sure that you know the type of filament used in the 3D printer you choose.

- Build Volume: The build volume of a 3D printer refers to the dimensions on which you can print carbon fiber models. If you know what you are buying the 3D printer for, make sure you have an idea of the dimensions as well. This way, you will be able to buy one that can easily print your required designs in the size you want.

- 3D Printer Style: While this may not seem to matter as much, but it’s always best to know the kind of printer styles you can opt for. Commonly, you could choose the Fused Deposition Modeling (FDM) style, and other styles include Digital Light Processing (DLP), Stereolithography (SLA), Selective Laser Sintering (SLS), and much more.

- Safety Features: 3D printers are built with many safety features to ensure the effectiveness of the printing process and the efficiency of the machine. Usually, FDM 3D printers cool the nozzle and heated bed after the printing process is complete. Some 3D printers also move the nozzle away after the job is paused or completed to avoid heat damage or excess filament.

Benefits of Using Carbon Fiber for 3D Printers

There are a number of benefits that you can reap while using carbon fiber for 3D printing and the main ones are listed below:

High Tensile Strength

When it comes to tensile strength, carbon fiber composites have a higher value than ABS, PETG, Nylon, or any other materials used in 3D printers.

This makes them ideal for building parts, prototypes, and many other products in various industries, such as automotive, aerospace, and many others.

Lightweight

Another benefit of carbon fiber filaments is that they’re lightweight, as they have a low weight-to-strength ratio.

This is why they’re used for various applications where they can replace metal products, especially those made from aluminum. They provide the same amount of strength with a much lower weight.

Low Thermal Expansion

Carbon fiber filaments don’t deform or change their shape easily when exposed to heat, which means that they’re more heat-resistant and corrosion-resistant than other composite materials used in 3D printing.

In addition, the fiber prevents the model from shrinking after cooling down, and this results in a better finish.

Base Material Enhancement

Not only is carbon fiber a strong material, but it also strengthens and enhances the base material it’s mixed with. By mixing it with Nylon, ABS, or any other strong base material, increases the resultant material’s rigidity and stability, thus preventing warping or shrinking.

Cost-Effectiveness

Since carbon fiber filaments are used to print objects that can replace metal and plastic parts, this makes them automatically more cost-effective than other materials.

This also brings about a decrease in production costs for various industries.

Disadvantages of Using Carbon Fiber for 3D Printers

Just as there are advantages of using carbon fiber, there are also a few disadvantages, listed below:

Nozzle Damage

Carbon fiber filaments don’t melt during extrusion as other materials do. This is why they are more abrasive and can easily damage or block the extruder nozzle.

One major reason for this is that the carbon fiber material is stronger than the nozzle material. To remedy this, you will have to buy hardened steel nozzles.

Clogging

Another problem with carbon fiber filaments is that they are more brittle and hard than other composites.

Therefore, they can easily break on the way from the spool to the nozzle, which severely affects the quality of prints. Avoiding this issue can be quite difficult, as it requires you to remove any sharp bends in the path from the spool to the nozzle.

Surface Finish

Different carbon fiber filaments have different kinds of surface finishes, which is due to the varying ratios of base material and carbon fiber material that companies mix.

Lower amounts of carbon fiber may improve the quality, but if a certain level is crossed, it may deteriorate the quality of your prints. Therefore, you have to pay close attention to the ratios.

Conclusion

This brings us to the end of our buyer’s guide for the best carbon fiber 3D printers you can buy. Our top pick is the Ultimaker S5, as it’s highly affordable and can be easily used for industrial-level printing.

No matter which carbon printer 3D printer you choose to fulfill your printing requirements, make sure to weigh it against the factors that we’ve outlined above.

They’ll help you make an informed decision and pick a 3D printer that not only provides you with high-quality prints but also has a range of helpful features and value-added options.