Compare 3D Printers and 3D Scanners Offers

Best place to find additive manufacturing equipment for beginners and professionals. Compare great value prices or get quotes now.

Filter

Showing 1–30 of 58 results

PROS:

- Modularity for a Scalable Factory Solution.

- Uniform, Repeatable Quality

- Metal 3D Printing with Lower Part Costs

- High Productivity

- Seamless Large Parts

CONS:

- Cost may be an issue for most of the people willing to buy this 3D printer.

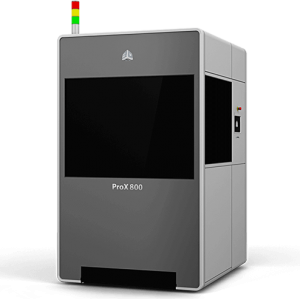

PROS:

- Easy changing of materials.

- Single source solution.

- Ease of use because of integration.

- Good quality parts and functional prototypes

- Integrated management system.

- Large-scale application of parts and functional prototypes.

CONS:

- The cost of this printer is something not everyone can afford. So, one needs to see a long-term future in the 3D printing industry before buying this printer.

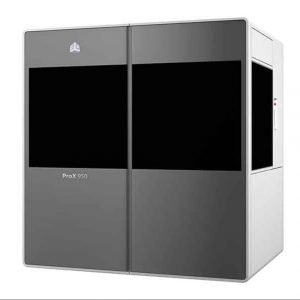

PROS:

- Huge build volume.

- High-quality parts and functional prototypes.

- Great print speed.

CONS:

- The cost of printing per part is greater.

- Resins are expensive.

PROS:

- Big build volume

- High accuracy of parts and functional prototypes

- Cleaner and safer printing environments

- Integrated solution for manufacturing parts and functional prototypes

- Builds objects that can be used in various industries

- Conformal Cooling

- Large tool inserts

CONS:

- By mentioning the features of this printer in a little more detail would have done tons of good in explaining the printer, rather than just plainly stating the claims

- The printer is very expensive and is hardly affordable for someone who runs a small business

- The overall printing cost per part on this printer, when compared with other printers in the same price range but built on a different technology is higher

3DCeram C3600 Ultimate

C3600 Ultimate is an industrial-grade 3D printer based on the Stereolithography technique of 3D printing which comes with a free link support technology at a reduced price per part is available on there. PROS:

- Bigger build volume.

- Reduced cleaning time.

- Good speed.

CONS:

- Expensive in cost.

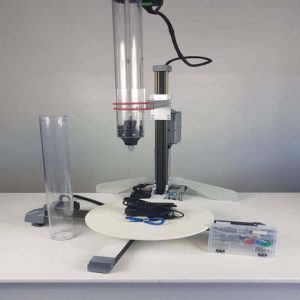

PROS:

- The printer has an open design, so there is a lesser issue while post-processing.

- The company uses real clay in making and also offers factory-made clay for you to use.

CONS:

- The printer is a little on the expensive side.

PROS:

- Open design.

- Post-processing is easy.

CONS:

- Temperature generation is an issue.

PROS:

- Scara V4 has an open design, so there is a lesser issue while post-processing.

- The company uses real clay in making and also offers it to its customers. This is a factory-made clay for you to use so that increases the overall quality of parts and prototypes manufactured by it.

CONS:

- The printer is a little on the expensive side. So, if you are a small business owner you may not find it as affordable as you may other printers.

PROS:

- By displaying complete information about the technology, the company has given the complete idea to its users to compare with other technologies out in the market.

- You can print with powder as well as with wire using Additec uPrinter.

- The company gives you an option to customize your printer to your needs, in terms of an upgrade.

CONS:

- There are not many pictures of parts or functional prototypes that are manufactured using this printer.

PROS:

- You can produce large components.

- Quickly switch materials.

- You can custom your needs.

- The machine has increased efficiency.

CONS:

- For those who haven’t used DLP printing technology, the cost of this printer may seem very high.

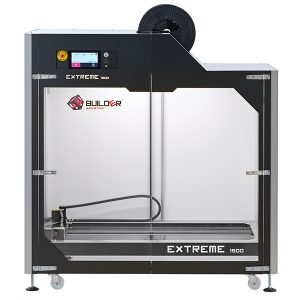

PROS:

- Seven in touch screen display lets you operate as well as monitor the 3D printer from one screen.

- The printer is easily transportable from one place to the other.

- It has filament detection as well as a UPS system.

- The bed calibration, as well as leveling of this printer, is automatic.

- It offers a huge build volume.

- The printer lets you print with nozzles of different diameters.

- It comes with an easy operate software i.e., Simplify 3D.

CONS:

- Price might be an issue for a lot of small enterprises functioning in the field of 3D printing technology.

PROS:

- Scalable solution for the users

- Creates isotropic parts

- Compatible for various different applications

- Easy to operate

- Can work in tandem with Carbon’s part washer

- High-speed resin printing

CONS:

- Build space is not very large

- Costly for small businesses

- Detailed Information about the product isn’t available handy on the website

PROS:

- t is huge and can manage to print a complete car frame in one go

- Allows for open source material use

- Multiple material support

- Faster than almost every other industrial printer out there offering large model 3D printing

CONS:

- Very Expensive

- Not available commercially for purchasing

- The accuracy and details may feel unsatisfactory to many

PROS:

- Concept Laser XLine 1000R is a very precise SLM 3D printer

- It is reliable

- One can create multiple metal parts in a matter of hours.

- It offers the user a smoother finish and can create complex geometries without any restrictions

- One of the best Metal 3D printers for industrial use

- The speed is also faster than most of the SLM 3D printers out there

CONS:

- The 3D printer is very huge, hence it's not easy to move from one place to another weighing around 8000 kgs. Hence, not suitable for personal use at home. Dedicated to industrial applications only.

- Moreover, the price is way too high for an individual to afford

PROS:

- No-hands on production concept.

- Printing happens at room temperature.

CONS:

- There is no gallery wherein pictures of parts and functional prototypes are displayed which gives you a little more idea about the accuracy that the company is stating all along.

PROS:

- Easy to operate

- Sleek design

- Plug and play

- High precision

- Comes with one year warranty

- Twice as fast as traditional methods

- Parts look and feel like traditional gypsum models

CONS:

- Very expensive

- Smaller build space

PROS:

- Intricate detailing of parts possible.

- User friendly.

- Industrial-grade 3D printing possible.

CONS:

- Small build volume.

PROS:

- There is a separate tab of success stories that tell about which printer was used in which industry to generate what!

- If you plan to be an EOS customer, there is a lot to gaze all over the website and learn from.

CONS:

- The website is too long. And, so if you are not used to navigating in a proper fashion, you might get lost!

PROS:

- Excellent management of various aspects of 3D printing process is possible using various parts of this 3D printing system.

- No need for any support structures.

- An extraordinary quality of parts and functional prototypes for various applications are possible using this 3D printing system.

- You can choose from a variety of different 3D printing materials.

CONS:

- The high cost of printing per part when compared with other 3D printing technologies.

- Relative to other melted parts, DMLS parts are porous and their porosity can be controlled but not eliminated in the 3D printing process during post-processing.

PROS:

- Huge build volume.

- Four different laser sources for melting and fusing, leading to consistency in the overall surface of the part or functional prototype.

- Multi-material printing.

- Good quality part and functional prototypes.

CONS:

- Requires huge one time investment.

PROS:

- Four high-power laser sources to ensure coherent melting and fusing of metal powder and excellent surface finish in parts and functional prototypes.

- Sophisticated material management and software systems for ease of use and operation after, before, and during the 3D printing process.

- Ability to print with various 3D printing materials.

CONS:

- Buying EOS M400-4 or even leasing it, requires a huge one-time investment, monetarily as well as in training and operation.

PROS:

- High-powered laser

- Laser Power Monitoring with Gas Management System

- Stand-alone automatic powder-sieving

CONS:

- The cost of the printer is something many might have a problem with.

PROS:

- Helps to achieve amazing print quality with high strength.

- Offers a huge range of materials.

- Supports third party slicing software.

CONS:

- Post-processing of every part and the functional prototype is required.

PROS:

- Patented quality for 3D printing of parts and functional prototypes.

- Highest build volume offered.

- Adjustable print speed.

CONS:

- The price of the printer would be judged as on the higher end by the users of technology like FDM and SLA.

PROS:

- High-speed process for additive manufacturing.

- Large available envelope for substantial size parts.

- No melting characteristics.

- Bonding of dissimilar metals.

- Metal matrix composites.

- Smart or reactive structures.

- Low-temperature process.

- Complex internal geometries.

- Requires no post-processing on parts and functional prototypes.

CONS:

- Cost is a huge issue with every industrial printer and Fabrisonic Sonic Layer 4000 falls in that range. So no one can help it when users are more concerned about cost than quality and quantitative manufacturing in less time.

PROS:

- Highly productive.

- Reduces cost per part by 10 percent.

- Powered by highly effective 4.5 Kilowatt electron beam.

- Capable of mass-producing.

- Amazing design freedom.

- Able to print faster.

- Comes with an efficient PRS-30.

CONS:

- The printer and its components take up huge space so users will have to have a good amount of infrastructure dedicated for this giant piece of industrial 3D printer.

PROS:

- The machine is capable of maintaining powder integrity to ensure optimal part production;

- It features a 100% increase in power as well as 50% faster build times

- Withstand higher heat more than 1000 degree Celsius allowing the incorporation of more alloys

- Allow larger parts 3D printing and more numbers of parts at a time

- Automating most of the processes that needed manual intervention before and providing optimal quality control

- Faster speed and takes lesser time for production

- Increased part printing quality

- User-friendly and simplified processes introduction for operators

- Easy to validate and improvement in the uptime

- Increased efficiency

CONS:

- Post-processing requirement

- Not compatible with plastic or polymer or ceramic materials

- Expensive and huge in size

- Specific to industrial use

PROS:

- Automated mixing, sieving, and loading of material

- Plug and Play

- Fast cooling

- External storage tank

- Large build volume

CONS:

- Expensive

- Occupies large space

PROS:

- Printing with five different 3D printing materials.

- Post-processing of parts and functional prototypes is easy.

- High-class software solutions.

- Huge build volume.

- Good quality parts and functional prototypes.

CONS:

- The cost of this 3D printer is too high for any beginner to even think of paying it. Even if you are a 3D printing professional you have many other options to deliver a similar range of quality at a much lower price.

PROS:

- Accurate functional parts with intricate detailing.

- Complete coloring of parts is possible with voxel control.

- The speed of this 3D printing system is tremendous.

- You need no support material.

- It reduces waste.

CONS:

- Although the company claims it as a suitable 3D printer for offices as well as domestic use, you can hardly manage the complexities the printing systems bring to your place.