Are you willing to establish your own 3D printing venture? If yes, then there are endless possibilities. Additive manufacturing is the latest technology. Initially, it was only accessible to the elite class and industrialists. But now companies have come up with various affordable 3D printers.

Its market is continuously innovating and extensively expanding providing various opportunities to small entrepreneurs to start a business by offering creative solutions.

The technology uses Computer Aided Designs (CAD) to create different 3D objects that you can sell and earn millions. It has aided various industries.

These include medical, automobile, architecture, aeronautic, and agriculture, etc. By 2025, it is expected that the global 3D printing market and services will reach $50 billion.

This article assists you with numerous additive manufacturing business ideas and lists down the 15 best 3D printers mostly used for establishing these startups.

3D Printing Startup Opportunities

Here are a few ideas for starting a small business by using a 3D printer:

Children Toy Shop

There is always a great demand for children’s toys as these keep them busy and entertained for a couple of hours. Thus, this venture is quite profitable. You can easily create unique 3D dolls, figures, bath toys, toy cars or trucks, and blocks.

Customized chess and board game 3D pieces are also in great demand as these enhance the game experience due to personalization. You cannot only target the local market but also the international market by selling online and exporting those.

Prototyping

3D printers enable rapid prototyping. Many industrialists look for 3D printing experts to efficiently and quickly produce high-quality models of their designs for testing and evaluation before manufacturing their final products commercially.

You can successfully start a business by creating prototypes for others. The production cost is low. Thus, there are great profit margins.

Jewelry

Many jewelry artists use 3D printers to create unique fancy accessories such as rings, earrings, and bracelets.

These devices help you to create highly intricate designs efficiently and quickly. Now companies have come up with printers that use metal, nylon, and other materials that are specific to jewelry making.

Spare Parts

Specializing in making cheap 3D spare parts of vehicles, machines and other tools will be quite lucrative. Many giants face difficulty in producing individual parts in-house and stocking them.

Also, there might be a delay in shipping those parts when repair and maintenance are required. Thus, you can collaborate with local service providers and tradesmen to offer these parts.

Custom Made Tools

Doctors, dentists, engineers, mechanics, and manufacturers require customized tools to offer their services efficiently. By specializing in producing and selling these tools, you can earn millions.

3D Printing Educational Centre

You can also start a business by teaching additive manufacturing technology to children and others who are willing to learn it for their personal or business use.

You can educate them with basics and advanced things related to 3D printers. One can also learn by writing blogs and vlogs about 3D printing.

The list of ideas goes on and on. You can also produce and sell 3D printed shoes, apparel, home decorative items, kitchen cutleries, medical pills, and architecture models, etc. You can also set up a small 3D cinema and selfie studio for people’s entertainment.

15 Best 3D Printers to Start a Small Business

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Original Prusa i3 MK3 | auto calibration | 7.9 | |

| Makerbot Replicator Plus | Fast Print Speed | 8.8 | |

| Elegoo Mars 2 Pro | Best for Jewelry | 8.9 | |

| Lulzbot Taz Pro | Open Source | 8.6 | |

| Monoprice MP Maker Pro Mk. 1 | User friendly | 7 | |

| Zortrax M300 Plus | Plug and Play | 8.8 | |

| Toybox | Best Toy 3D Printer | 8 | |

| Raise3D Pro 2 | Most precise | 8.4 | |

| Ultimaker 3 Extended | Top Rated | 9.4 | |

| Modix Big 60 | Runner up | 9.1 | |

| Formlabs Form 2 | Best Slicer Software | 7.6 | |

| Raise 3D N2+ | Versatile | 8.1 | |

| 3D Systems FabPro 1000 | Highly professional | 8.8 | |

| Sintratec Kit | Most Compact | 8.6 | |

| ZMorph VX | All in One | 7.7 |

Original Prusa i3 MK3

|

The Original Prusa i3 MK3 is the successor of its award-winning predecessors. It also gained popularity among customers due to its new extruder system and other updated features.

The printer is open source with a build volume of 250 x 210 x 200 mm and a PEI coated removable print bed. You can connect to it through a USB port or an SD card.

It uses proprietary software for slicing and is compatible with MAC, Windows, and Linux. It comes both as assembled and a DIY kit.

The kit costs $900. You can buy the kit and assemble it yourself to save money.

Uses:

- It is a great option for beginners and serious learners as there is a lot to learn from assembling and operating it.

- You can create miniatures for fun and sell those for money.

- The new extruder placement enables easy changing of the nozzle without the need of redoing the whole assembly line and improves print quality by minimizing resonance and enabling better cooling of the parts.

- The optical filament sensor is reliable and is compatible with all types of filaments.

- Due to quiet operation, you can use it in homes and small offices without disturbing others.

- You can use a third-party filament to minimize material costs.

- Power recovery

- Open-source

- Third-party filament

- 9 points auto-calibration

- Quiet operation

- Requires assembling or have to pay extra for fully assembled one

- Poor layer adhesion

- Open frame

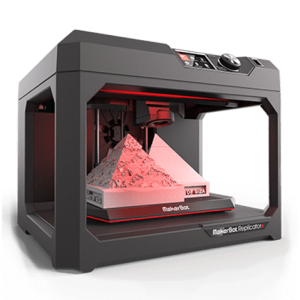

Makerbot Replicator Plus

|

Makerbot Replicator Plus is the improved version from the Makerbot 3D printers’ family. It is quieter and has many unique features that make it stand out among other printers of similar price ranges.

The device is 25% larger and 30% faster than its predecessors. It has a black sleek body with an open frame.

The printer has a large built volume of 6.5 x 11.6 x 7.6 inches and weighs 18.3 kg. It is based on Fused Deposition Modeling (FDM) technology and is easy to set up. You can connect to it through WIFI or USB. It is compatible with Makerbot Software, which is user-friendly.

You can have a hand on this professional machine by investing only $2499. The company offers great customer service after the purchase.

Uses:

- Makerbot Replicator Plus is best for architectures to create precise models, small businesses for general 3D printing, and trainers for teaching 3D printing.

- Due to hollow sides, front and top, it allows you to keep an eye on the printing process.

- You can easily control the printer’s settings through a control panel that is located at eye level. There is one push button wheel and two other buttons that help in navigating the display. Before printing, the preview of the design can be easily viewed on a cellphone or desktop.

- It enables you to choose between 30 different filaments. The filament is stored externally which enables you to check its level of usage and easily load and unload it.

- Buy a smart extruder with the printer to keep track of the low level of filament.

- The machine produces straight lines with perfection. It is good for 3D printing complex geometric structures and sculptures.

- Sturdy body

- Large print space

- Easy to set up

- Wi-Fi connectivity

- Decent output quality

- Remote monitoring

- High speed

- Bit pricey

- USB connectivity issues

- Nonheated print bed causes warping

- Cannot use third party filament

- Open frame poses a risk of burning upon touch

Elegoo Mars 2 Pro

|

Interested in setting up a 3D jewelry business? If yes, then Elegoo Mars 2 Pro should be your go-to option. It has made a name for itself in a highly competitive market as an easy-to-use machine with high functionality.

It is the successor of the Elegoo Mars 3D Printer and you can get it just by paying $50 extra. It offers 5% faster print speed, a special filter, and high-quality output.

The printer has a built volume of 4.53 x 2.68 x 5.9 inches with a print speed of 30 to 50 mm/sec. It has a matrix UV Led that prints with a layer resolution of 0.01 to 0.2 mm.

You can connect to it through a USB or WIFI. Also, it has an aluminum sturdy body that minimizes vibration during producing large parts or functional prototypes.

The machine costs $329 only.

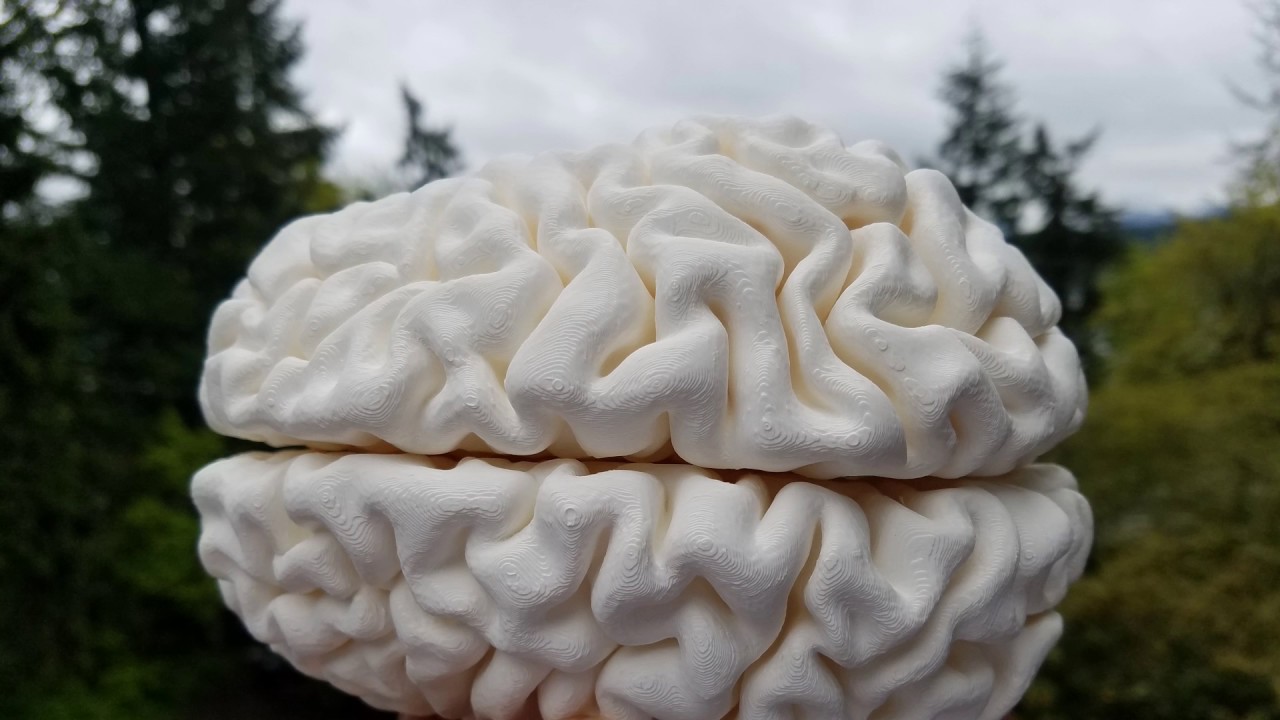

Uses:

- It is great for jewelers and architects to produce highly detailed complex geometric patterns with fine lines using the matrix UV LED.

- It is also best for bioprinting and creating historical structures and sculptures for schools and museums.

- The carbon filter removes any harmful particles and smells, making it safe to be used in homes and small offices.

- The lightweight and compact design make it portable.

- Simple to use

- High speed

- Precise

- Sturdy frame

- Carbon filter

- 1 year warranty

- Loud

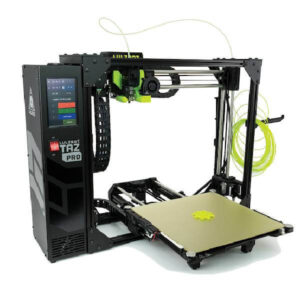

Lulzbot Taz Pro

|

Aleph Objects has always impressed users with its affordable 3D printers that offer professional results. It has come up with great options and each one has raised customer expectations.

To cater to high expectations, it launched Lulzbot Taz Pro in March 2019. It is their first industrial-grade 3D printer with a large build volume and dual extruder.

The printer has a build volume of 280 x 280 x 285 mm. The layer resolution varies from 0.05 to 0.4 mm. It is compatible with a wide range of materials and Cura software. It costs around $4950.

Uses:

- It is best suited for professional and industrial applications due to the E3D Titan Aero extruder and 0.5 mm steel nozzle. It allows printing with abrasive materials.

- The PEI-coated print bed enables better adhesion of the first layer.

- The open frame ensures consistent airflow and allows a better view of the printing process.

- The machine offers accuracy with 360 degrees part cooling. It enables printing complex designs with ease.

- The automatic nozzle cleaning system cleans the hot ends against the pads inside the machine before every print.

- The automatic bed leveling has been upgraded by X/Y/Z axis offset calibration.

- The 5 inches LCD screen offers an intuitive interface and helps to control the settings of the printer.

- The dual extruder allows printing with two different materials and also supports water-soluble to create models with a smoother surface finish.

- Automatic bed leveling

- Good print speed

- Large build space

- Filament run-out sensor

- Open-source

- No Wi-Fi connectivity

- No remote monitoring

- Pricey

Monoprice MP Maker Pro Mk. 1

|

MP Maker Pro Mk.1 is the last 3D printer introduced by the company. It resembles Wanhao Duplicator D9 in many ways and is based on FDM technology. It comes fully assembled by the company and has an open sturdy aluminum black frame.

The printer has a print space of 300 x 300 x 400 mm and a speed of 70 mm/s. It has a nozzle of 1.75 mm, an intuitive LCD screen, and is compatible with Cura. It requires an investment of $339 only.

Uses:

- It enables you to start a small venture by producing large-size parts and functional prototypes for the aerospace, jewelry, and toy industry or teaching children.

- The open frame allows for consistent airflow that helps to cool down the object simultaneously for better accuracy.

- The machine itself detects the filament run-out and indicates it to the user by pausing printing.

- It is also great for beginners due to automatic calibration and magnetic removable print bed.

- You can use third-party filament and print with ABS, PLA, and PETG.

- Huge build space

- Easy to use

- User-friendly interface

- Magnetic build plate

- A sturdy frame minimizes vibration

- Slow speed

- Not for temperature sensitive materials

- Risky to use around children

Zortrax M300 Plus

|

A Polish company, Zortrax has gained a lot of fame for continuously contributing to the additive manufacturing niche market. It aims to offer a complete ecosystem that includes great 3D printers along with a wide range of materials and an in-house slicing application to its consumers.

M 300 by Zortax is easily accessible and offers high-quality results. The printer has a build volume of 300 x 300 x 300mm with a nozzle of 0.4mm. The layer thickness varies from 90 to 290 microns. It is inbuilt with filament run-out sensor, three cooling fans, and other features that inspire people in every walk of the profession.

The machine costs $3590.

Uses:

- It is best for serious buyers and creators. It serves businesses in a wide range of applications.

- It is safe to use this printer due to its enclosed chamber. The closed frame also allows printing with tricky materials by maintaining a consistent temperature inside.

- It enables seamless 3D printing due to its sturdy metallic body that minimizes vibration at high speed.

- The automated bed leveling eases calibration for beginners.

- You can remotely monitor the 3D printer through WIFI due to the inbuilt camera.

- You can control the machine through an intuitive 4 inches touchscreen that is easy to operate. It allows users to preview the 3D model before printing and make necessary changes.

- The machine is also compatible with third-party filament Thus; it enables you to manage the production cost.

- HEPA filter helps to filter out harmful dust particles and fumes up to 99%, thus, making it safe to be used in a closed and less ventilated area.

- The enclosed frame makes it safe

- Eco friendly

- Easy to set up

- Plug and play

- Wi-Fi connectivity

- Remote monitoring

- Pricey

Toybox 3D Printer

|

Are you interested in creating unique children’s toys and selling them? If yes, then the Toybox 3D printer is a great option to be considered. With just an investment of $325, you can have a simple and compact device to produce toys quickly and easily.

The printer has a print space of 3.5 x 3.1 x 2.8 inches and a speed of 60 mm/sec. You can print with PLA non-toxic plastic with a resolution of 200 microns. It has an open frame with an easy-to-peel print bed.20463

Uses:

- It enables you to start a new small venture of unique and innovative toys for kids at home.

- You can involve kids in making their own plastic dolls, cars, cutlery, miniatures, etc through this printer. This will enhance their knowledge of science and technology.

- The machine settings can be controlled through an LCD touchscreen or Make. Toys application.

- A wide range of toy designs is available. You can either print those or modify them or create your own design from scratch through its Creator Space.

- The open frame allows you to keep track of the printing process and easily access the print bed.

- Easy setup

- Portable

- Sturdy body

- User friendly

- Cheap

- Small build volume

- Cannot leave with kids unsupervised

Raise3D Pro 2

|

Raise3D Pro 2 has raised the bars for others. It provides the consumers and prosumers with all the features they need for day-to-day work.

It has all the great features of its predecessors along with other improved ones. It is appealing to all those who tend to seek professional experience.

The printer has a build volume of 305 x 305 x 300 mm with a speed of 150 mm per second. It comes pre-calibrated and fully assembled. You can connect through WIFI, LAN, and a USB port.

The machine costs $3999.

Uses:

- It is used for a wide range of applications from producing prototypes to end products. Also, it is compatible with various materials. This extends the possibilities to a greater extent.

- The printer has a dual gear-driven extruder that is 50 percent faster than those in predecessors. It includes an enhanced filament grip that offers reliable extrusion of material.

- You can easily change the magnetic swappable aerospace-grade build plate when required.

- It enables you to create precise and highly detailed geometric structures with a minimum resolution of 0.01 mm.

- HEPA filter helps to filter out harmful dust particles and fumes up to 90%. Thus, making it safe to be used in a closed and less ventilated area.

- The machine indicates when the filament is running low and pauses printing for the user to refill it.

- When there is a power failure the printing pauses and the print process is saved. After power recovery, printing resumes from where it stopped. This saves from huge losses.

- You can remotely monitor the 3D printer through WIFI due to the inbuilt camera.

- Supports multiple materials

- High precision

- Reliable

- The heated and removable print bed

- Enclosed chamber

- Eco friendly

- Expensive

- Large in size

- Tricky slicing software

- Difficult user interface

Ultimaker 3 Extended

|

Ultimaker 3 Extended is a workhorse that is used for specialized purposes. It is extremely reliable with dual extrusion.

It enables you to create unimaginable designs with high accuracy and speed. It is easy to use and requires less maintenance. This device is a next-generation machine with great features.

The printer has a large build volume of 215 x 215 x 300 mm with a speed that varies between 30 to 350 mm/s. It has a nozzle diameter of 0.4 mm that can print with a resolution of 20 to 200 microns.

It is compatible with Cura, open-source software that is user-friendly. You can connect to it either via LAN, USB port, or WIFI.

You only require an investment of $4295 to get this amazing printer.

Uses:

- It is best for small businesses that are willing to scale up their setup. It is used in the medical, aerospace, and jewelry industries to produce intricate outputs.

- You can work on this printer for hours without any hassle.

- The machine allows you to print with two colors and materials simultaneously. It is also compatible with PVA, allowing you to create a support that is water-soluble.

- Due to the material recognition feature, Ultimate 3 extended automatically recognizes the material used and optimizes its setting automatically through Cura.

- You can remotely control and operate the printer through WIFI connectivity, cloud access, and an inbuilt camera.

- It is also great for beginners due to plug-and-play features and automatic calibration.

- It enables you to use third-party filament; both standard and premium.

- Open source

- Noiseless

- Dual Extruder

- High precision

- Low maintenance

- Bit pricey

- Auto calibration sometimes does not work properly.

Modix Big 60

Big 60 is the flagship 3D printer of the company, Modix Large. It was launched in 2017 as a DIY kit and now its third upgraded version is available. It is affordable with a large build volume and premium components. It comes with an E3D Titan Aero extruder and E3D volcano hot end.

The printer has a print space of 600 x 600 x 660 mm and is based on FDM/FFF technology. The layer resolution varies from 40 to 800 microns.

It has a PEI coated heat build plate with an automatic bed leveling feature. You can connect with an SD card, Wi-Fi, and USB. Big 60 is compatible with Slic3r, Cura, and Simplify3D software.

The machine is priced at $3700.

Uses:

- It is mainly used for prototyping, restoration, and research and development in industries such as automatic, education, entertainment, and consumer products.

- The removable print bed enables you to easily take out the models after completion.

- It saves your production time due to exceptional print speed.

- The Duet3D WIFI mainboard enables you to connect it with multiple devices.

- The dual-zone silicon heater helps to save power while printing efficiently.

- Compact footprint

- Large build volume

- Reliable

- Easy to operate

- Requires assembling

Formlabs Form 2

|

The most highly demanded SLA 3D printer from Formlabs is Form 2. It is economical, reliable, and professional with numerous features for consistent quality and high-resolution 3D printing. It has great power and potential to produce complex structures.

The printer has a print space of 145 x 145 x 175 mm with a resolution of 25 microns. It weighs 13 kg and has auto heating technology. It is compatible with Mac OS, Windows 7, and later versions. You can connect through Ethernet, USB port, and WIFI.

The machine costs $3499 and comes with a one-year warranty.

Uses:

- It is used for batch production and commercial use. You can use it to produce dentures, jewelry, and prototypes.

- It enables hassle-free printing without any connection once the file is uploaded.

- The Preform software enables the positioning of models to eliminate errors and enhance accuracy.

- You can import, resize, duplicate and align the 3D design through the layout tools.

- The smart support structure supports the constructions of the objects to get clean 3D prints.

- The touchscreen display indicates the printing progress and helps to control other parameter’s settings.

- Great output quality

- Hassle-free operation

- Best slicer software

- Good user interface

- Noise-free

- Post processing is required

- Slow

- Messy and difficult to change resin

- High consumable costs

Raise3D N2+

|

A US-based company offers two 3D printer lines for all types of projects. It is versatile in terms of volume and material. It is easy to use with an intuitive touch screen and Wi-Fi connectivity. It has an enclosed chamber with a heated build plate that allows you to print with tricky materials like Nylon and ABS.

The printer has a build volume of 12 x 12 x 12 inches with a print speed of 10 to 150 mm per second. The layer resolution varies from 0.01 to 0.25 mm and the accuracy is 0.00125 mm. It is priced at $999.

Uses:

- It is used to manufacture parts and functional prototypes in industries such as health care, jewelry, automotive, etc.

- The battery backup stores your progress before shutting down when there is a power failure. It ensures that you do not lose your work.

- The aluminum frame offers sturdiness and avoids wobbling during 3D printing. It is fully enclosed in an acrylic frame that enables one to keep an eye on the printing progress.

- The enclosed structure traps the heat inside and makes it safe to be used around children.

- The 7 inches color touchscreen allows you to control the machine. It is also accessible with WIFI and LAN. Thus, you can remotely monitor it easily.

- The heated bed and hot end enable you to print with a wide range of materials. These include PLA, ABS, PETG, Nylon, Carbon fiber, TPE, and TPU. You can also use metal composites by upgrading nozzles to wear resistance.

- The dual extruders enable you to print with two different colors or materials.

- Great print quality

- Large build volume

- Precise and accurate

- Versatile

- Safe to use

- Battery backup

- Large size

- Expensive

- Software compatibility

3D Systems FabPro 1000

|

A desktop 3D Printer, FabPro 1000 is specialized in the production of small objects with high resolution. It has a build space of 125 x 75 x 120 mm and a layer resolution between 30 to 50 microns.

The print speed is 21 mm/h. It is based on the DLP Stereolithography technology for 3D printing.

The printer will cost you $4126 and has a year warranty.

Uses:

- It is widely used by professionals in the dental, engineering, jewelry, and manufacturing fields.

- It prints three times faster than Formlabs Form 2 with great accuracy and surface finish. It also enables printing multiple parts simultaneously.

- The post-processing is simple. After printing, the user needs to clean the build plate with a solvent and then UV cure with the finishing kit that comes along with the printer.

- The machine is compatible with a wide range of materials from regular resin to the toughest engineering thermoplastics.

- 3D Sprint, the software, minimizes material wastage and supports structures.

- Fast

- Supports numerous materials

- Simple post-processing

- 22% lower production cost

- Highly professional

- Hard to set up

- Difficult to use

- Not for beginners

Sintratec Kit

|

A Swiss company, Sintratec, is known for its SLS 3D printers. In 2014, it launched its DIY desktop 3D printer kit for $5350. It takes four days to assemble but in return, it offers exceptional quality 3D prints.

The printer has a closed frame with a build space of 110 x 110 x 110 mm and a minimum layer resolution of 100 microns. It is only compatible with TPE and Nylon PA 12. You can connect to it through an SD card or USB and use third-party filament.

Uses:

- It serves various professional needs. It is used in making medical tools, durable industrial parts, rapid prototyping, mechanical engineering, education, research, and development.

- It enables you to print at a speed of 20 mm/h despite its complex design. However, it drops by 50% when printing with high resolution.

- The residual and unsintered powder serves as a support for 3D models. Once printing is completed, you can easily lift the model and brush off the excess powder.

- The printer enables you to minimize the production cost by using less material.

- You can print highly detailed complex structures with a tricky material like Nylon. This makes it stand out among other similar printers.

- Great print speed

- Good output quality

- Can print with Nylon

- No touchscreen

- A laptop required with an internet connection

- No built in camera

- Pricey

ZMorph VX

|

If you are looking for an ‘All in One’ 3D printer, ZMorph VX is a great option to be considered. It offers various functions with great features.

It comes with two extruders and one printing head that can have a diameter from 0.2 to 0.4 mm. By using proprietary software, Voxelizer 2, you can do advanced color mixing and texture mapping.

The printer has a build volume of 250 x 235 x 165 mm and layer resolution from 25 to 400 microns. There is a glass print bed for 3D printing and an aluminum print bed for CNC and laser engraving. You can easily connect to the printer via a USB port or SD card.

The machine costs $2800 with a one-year warranty. However, you can extend it to two years by paying a further $699.

Uses:

- You can use it to do 3D printing, laser engraving, and CNC milling.

- It is a multi-tool 3D printer that has CNC pro, and laser pro tool heads.

- The printer helps in mass printing. It holds up to four filament rolls. The dual extruders will use two rolls at one time and the other two are kept as backups.

- You can use different materials. These include plastic, ceramic, chocolate, or dough.

- The touch screen offers an easy user interface to control and monitor the printing process.

- It enables precise and accurate printing with automatic bed leveling.

- High print quality

- Versatile

- User friendly

- Efficient

- Automatic bed leveling

- Costly

- Print head usually get clogged

Buyers Guide

Choosing a 3D printer to start a small venture is not a piece of cake. You need to consider various parameters before making a purchase decision.

What Items Will You Print and Sell?

This is the first thing you should consider before even starting to search for a 3D printer for your business. It will help you to identify your goals and shortlist a few that best serve your needs. I

f you want to produce consumer goods with less turnaround time and more flexibility, then an FDM printer would be fine. But if you want to produce complex geometric structures and tools then go for an SLS or SLA 3D printer.

Price

It is one of the most important factors to be considered. It depends on your budget and how much you can invest to buy a 3D printer. If you have less than $500, do not worry! You can still buy a 3D printer with various advanced features and start up your business from home.

Multi Color 3D Prints

Most 3D printers only print in one color. If you want to produce multi-color 3D prints, then you should buy one that allows you to print with at least two colors simultaneously. These printers are easy to use and have full-color compatibility.

Build Volume (Width X Breadth X Height)

The larger the build volume, the bigger models you will be able to produce. If you want to produce large size parts, then you should consider a printer with a huge build space. Otherwise, you will have to produce different small parts of an object and assemble them later. This will impact your product’s quality.

Print Speed

The size of your model, the complexity of design, and the material used determine the speed of your 3D printer. However, you should look for one that prints fast as it will save your production time.

Material

Different 3D printers use different materials to print. Some use plastic and others use metal or ceramic.

The type of part or functional prototype you need to produce can determine the type of 3D printer that you need, as it should use the same material to print. You should buy a printer that uses a wide range of materials.

Working In an Office or Home

This impacts greatly. If you are starting your business from home, then you should buy a noise-free machine to not disturb old people at home. Also, when working around children and pets, ensure safety by buying a closed frame printer.

Frequently Asked Question (FAQs)

Is Starting A New Venture Of 3D Printing Profitable?

There is a great demand for 3D printed objects. Like all other businesses, it will take time and energy to set it up and turn your imagination into profit.

You can start by working as a freelancer if you have no experience. And then grow slowly once you gained confidence and made trustable clients.

Are There Any Courses Available For 3D Printing?

To have a better understanding and know-how of 3D printers, you can take up a course based on your expertise level. There are numerous courses available to cater to all learners’ needs from beginners to experts.

How to Choose the Best 3D Printer Filament?

The filament is the food of your product. A sustainable filament will increase the life of your output and a bad filament will negatively impact your brand name.

So, you should search thoroughly about those before purchasing in bulk. You can even ask for samples from a few companies for trial.

Conclusion

There are unlimited opportunities to start a small 3D printing business. Companies have come up with numerous 3D printers that cater to almost all professional needs. Choosing one to start up a new venture is difficult as you have limited time and a low budget. Thus, purchase one that is safe and has great reviews.